- 4 -

1300_GB-INHALT_2862

EN

Table of conTenTs

Observe

Safety

Hints in the

supplement!

Table of contents

TABLE OF CONTENTS

CE sign ...................................................................... 5

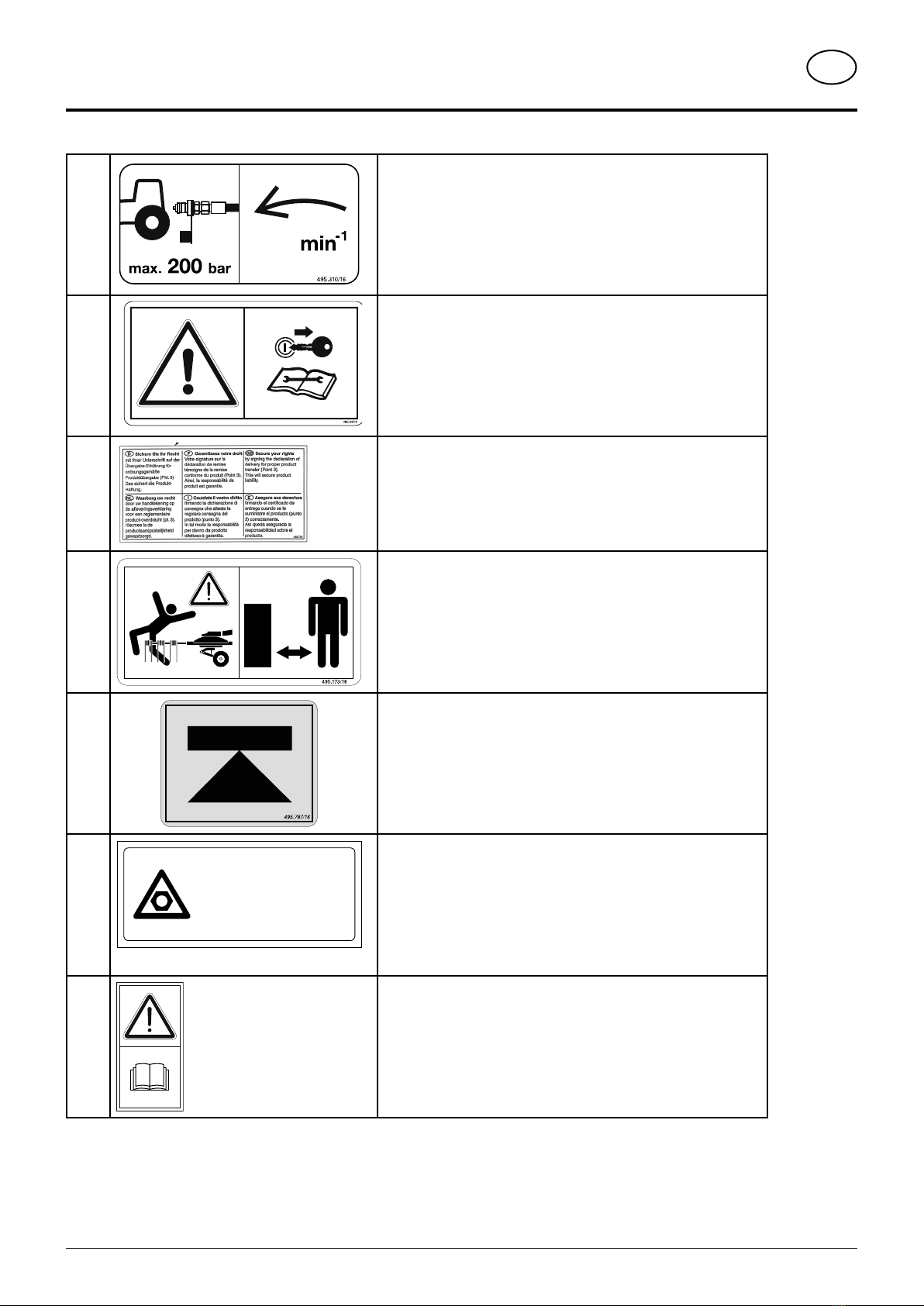

Meaning of warning signs.......................................... 5

SYMBOLS USED

CE mark..................................................................... 6

Safety hints: ............................................................... 6

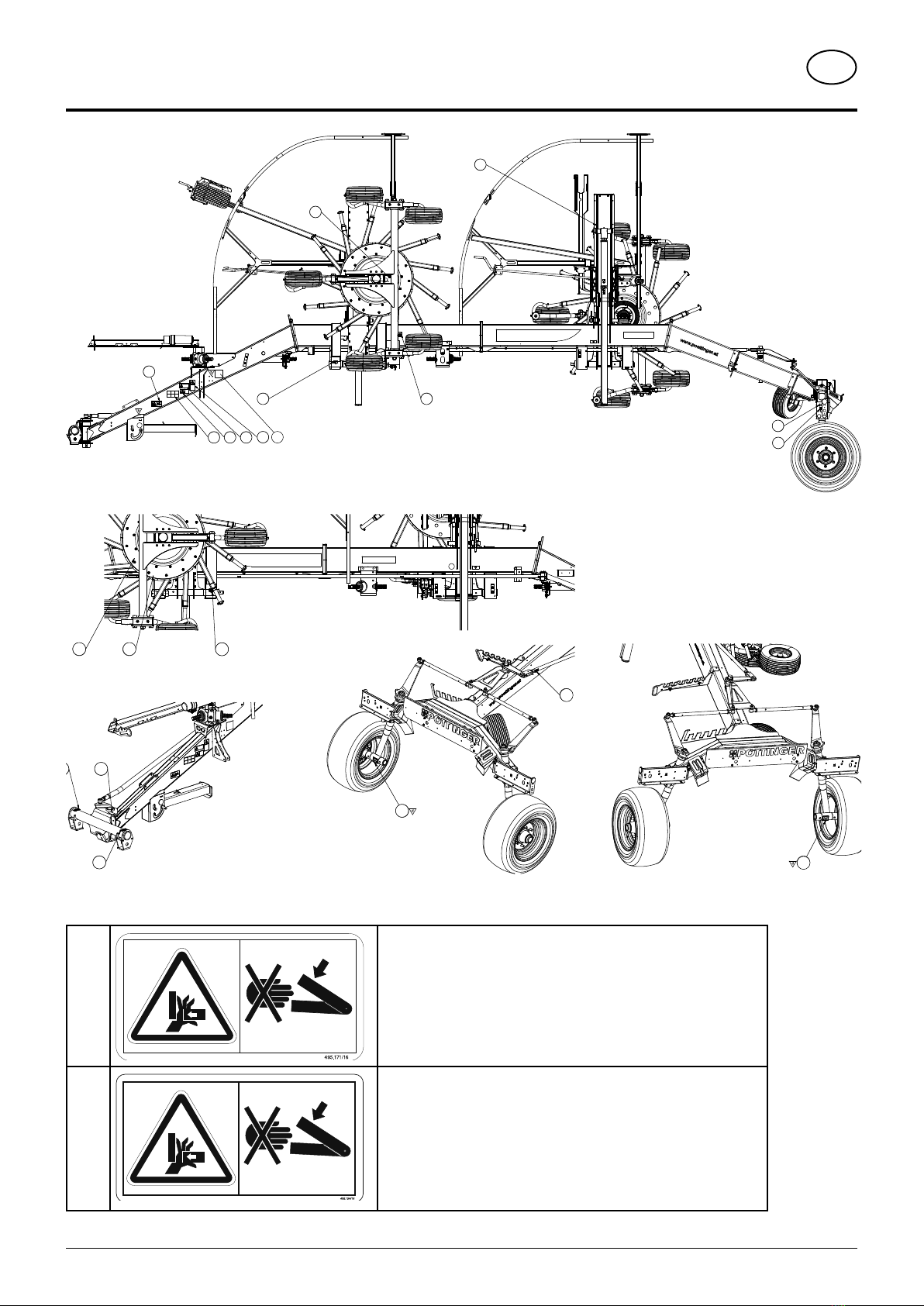

WARNING SIGNS

GENERAL SAFETY TIPS

Travelling with implement in tow .............................. 10

Coupling and uncoupling the implement ................. 10

Regulations for Use ................................................. 10

Travelling on roads................................................... 10

Before starting work................................................. 10

Checking before operation....................................... 10

DESCRIPTION OF SERVICES

Overview...................................................................11

Tractor...................................................................... 12

Ballast weights......................................................... 12

Lifting unit (three-point linkage) ............................... 12

Necessary hydraulic connections ............................ 13

Power connections required .................................... 13

ATTACHING THE MACHINE

Attach the machine...................................................14

Fold up support stand...............................................14

Make electrical connections......................................14

Hydraulic connections...............................................14

Fit cardan shaft.........................................................14

Securing of unbraked devices by means of a tear-off

chain .........................................................................14

Adjusting the linkage at the transport securing

device ...................................................................... 15

Setting the rotor relief (optional)............................... 15

Parking the machine ................................................ 16

Adjusting the rotor stabilisation.................................17

Safety advice ........................................................... 18

TRANSPORT

Conversion from working position to transport

position .................................................................... 19

Driving on public roads ............................................ 20

Machine dimensions in transport position................ 20

Frame - chassis ....................................................... 21

Reducing the transport height ................................. 22

Operation of the tine holder ..................................... 22

OPERATION

General guidelines on working with the machine .... 23

Conversion from transport to working position......... 23

Settings on rotor chassis.......................................... 24

1. Set the lateral incline............................................ 24

2a Set raking height (mechanically)......................... 24

2b. Set raking height (hydraulic) .............................. 25

3. Align indicators to one another ............................ 26

Adjust feeler wheels................................................. 26

Cardan shaft speed ................................................. 27

Rear swath apron..................................................... 27

Dual-swath function (Optional equipment for TOP

722).......................................................................... 28

Swivelling from working to field transport position ... 29

Step sequence control............................................. 29

Single rotor operation (variant) ................................ 30

Setting the cam track............................................... 31

WORKING ON INCLINES

Take care when turning on inclines!......................... 32

GENERAL MAINTENANCE

Safety advice ........................................................... 33

General maintenance information............................ 33

Cleaning of machine parts....................................... 33

Parking in the open.................................................. 33

Winter storage.......................................................... 33

Articulated shafts..................................................... 34

Hydraulic unit........................................................... 34

General instructions regarding maintenance work... 35

Transmission (1.2).................................................... 35

Chassis.................................................................... 35

Set tyre tracking....................................................... 35

Tyres ........................................................................ 36

Tine arms................................................................. 36

Spring tines.............................................................. 37

Lubrication diagram ................................................. 38

Rotor unit ................................................................. 39

Disposal of old equipment ....................................... 40

Raising the machine ................................................ 40

AIR BRAKE SYSTEM

Coupling the air brake hoses ...................................41

Safety advice ............................................................41

Maintenance .............................................................41

Line filter cleaning ................................................... 42

Adapting to the tyres................................................ 42

HYDRAULIC BRAKE SYSTEM

Safety advice ........................................................... 43

Coupling the brake hose.......................................... 43

Maintenance ............................................................ 43

Adapting to the tyres................................................ 43

HYDRAULIC PLAN

TOP 722 hydraulic plan ........................................... 44

TOP 722 hydraulic plan - single rotor operation....... 45

TOP 722 hydraulic plan - single rotor operation and

hydraulic release...................................................... 46

TOP 722 hydraulic plan - single rotor operation,

hydraulic release and raking height ......................... 47

TOP 722 hydraulic plan - dual swath operation ....... 48

TOP 722 hydraulic plan - flow divider (optional) ...... 49

Hydraulic plan for TOP 812...................................... 50

TOP 812 hydraulic plan - single rotor operation........51

TOP 812 hydraulic plan - flow divider....................... 52

TECHNICAL DATA

Technical data.......................................................... 53

Connections required TOP 722................................ 53

Connections required TOP 812................................ 53

Optional equipment:................................................. 54

Designated use of the swath rotor ........................... 54

Type plate ................................................................ 54

Type plate position................................................... 54

SUPPLEMENT

Lubricants ................................................................ 61

Combination of tractor and mounted implement...... 64