Pacbrake is a registered trademark of Pacbrake Co.

HP10002 & HP10089 AMP AIR SUSPENSION KITS L5682

3

L5682_REV19_ECN1-2194_01.13.2020

Thank you and congratulations for your purchase of a AMP air suspension kit.

IMPORTANT: The air suspension kit will not increase the GVWR (gross vehicle weight rating), as this is determined by the axle rating. Do not exceed the

maximum capacity listed by the vehicle manufacturer.

Before starting, ensure the application information is correct for the make, model and year of the vehicle you are installing it on. Please read the entire

installation manual prior to starting the installation to ensure you can complete it once started.

If installing a 10002 in a RAM 3500 Chassis Cab truck, install the appropriate Breather Relocation Kit (10136 for 2007-2018, 10349 for 2019+) BEFORE

installing the 10002 air springs. Follow the instructions provided within the 10136/10349 to do so. Installing the 10136/10349 Breather Relocation Kit is

only required for 3500 Chassis Cab vehicles with round axle tubes having the breather located approximately 7” from the drivers side leaf spring pack.

Pacbrake recommends using a good quality anti-seize on all fasteners, this will reduce the chances of corrosion of the fasteners, and help facilitate

removal if required at a later date.

1

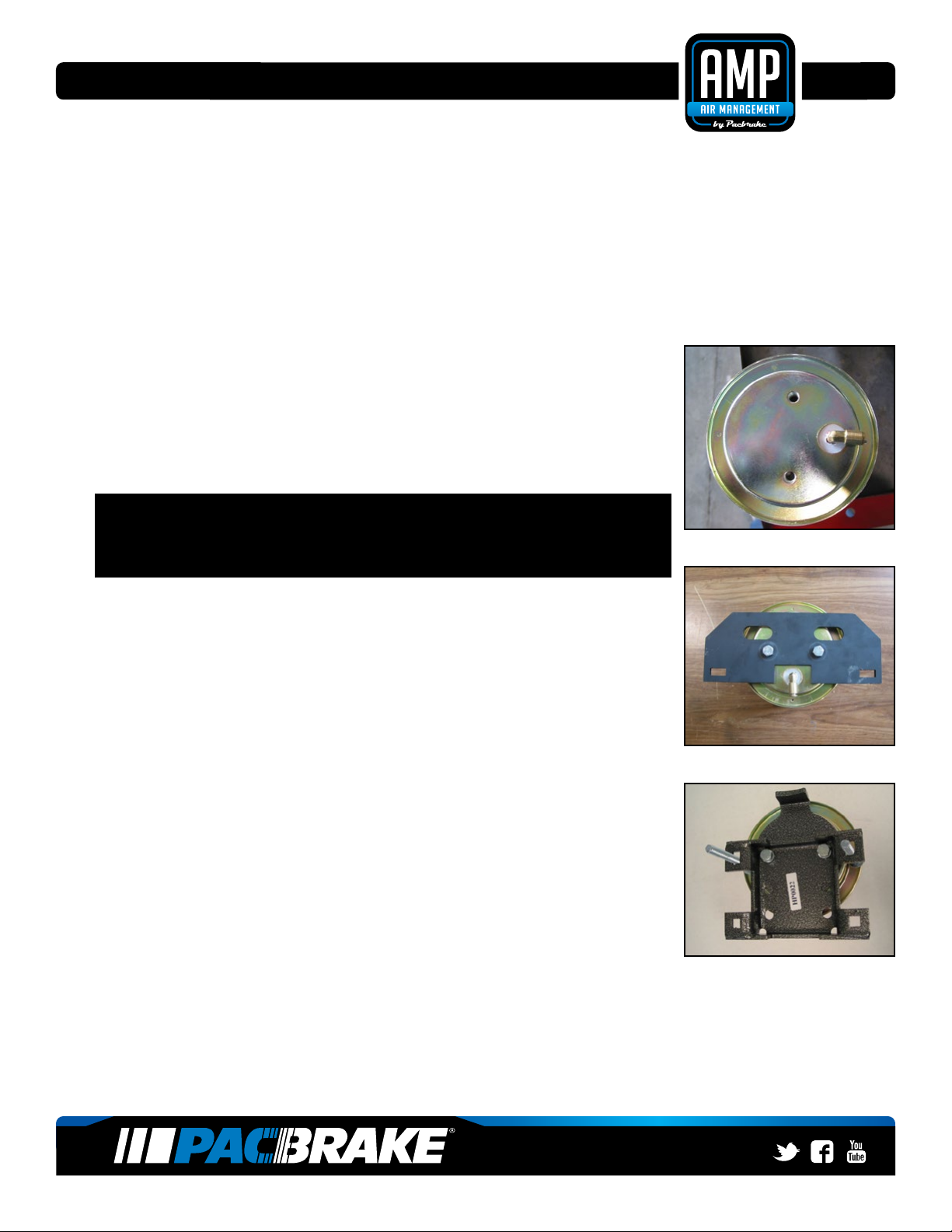

THE UPPER ROLL PLATE

Place the upper roll plate (with the rounded side towards the air spring) on the

top of the air spring (top being the end with the air inlet port). Install the air tting

supplied, use thread sealant to prevent air leaks. Repeat on the other air spring.

2

THE UPPER ROLL PLATE

NOTE: This kit contains 4 pieces of a 3/8”NF x 7/8” capscrews (upper bracket),

and 4 pieces of a 3/8”NF x 1” capscrews (lower bracket). It is Imperative that

these capscrews be identied before proceeding. Installing the incorrect capscrew

WILL cause the air spring to leak (and this will NOT be covered under warranty).

Place the upper air spring mounting bracket on top of the air spring and roll plate.

The upper air spring mounting bracket is identied by the two 3/8” holes next to the

air tting cut out. Using 2 - 3/8” NF x 7/8” capscrews provided, fasten the bracket to

the air spring. Torque both capscrews to 20 ft-lbs, 27 N•m.

3

THE LOWER PLATE & BRACKET

Place the lower roll plate on the bottom of the air spring (rounded side towards the

air spring). Locate the lower air spring mounting brackets and support plates.

Place the lower support bracket on the roll plate with the bent leg to the same

side as the air tting in the upper end of the air spring. The bent leg of the support

bracket must be pointing away from the air spring. Align the two holes in the

bracket with those in the roll plate and air spring.

The lower bracket is designed to be installed oset to the lower end of the air

spring. The oset must be opposite the air tting installed in Step 1. Two 3 long

arriage bolts must be installed into the two elongated holes of the lower bracket

before it can be fastened to the air spring and roll plate. Using 2 - 3/8NF x 1” long

capscrews and lock washers provided, fasten the bracket to the air spring. Torque

both capscrews to 20 ft-lbs, 27 N•m.

NOTE: The lower brackets have 2 extra sets of holes to t various applications, use only the mounting holes

shown in the photo for this application. When installed on the vehicle the lower bracket will be oset towards the

outside of the vehicle and the air inlet tting should be towards the inside of the vehicle.

Repeat steps 1 - 3 on the other air spring

STEP 3

STEP 2

STEP 1