Pacbrake is a registered trademark of Pacbrake Co. 1

HP10216 AMP AIR SUSPENSION KIT L6360

ECN 1-1789

L6360_Rev4_17.07.2018

KIT CONTENTS

REQUIRED TOOLS

• Hoist or Floor Jacks

• Safety Stands

• Safety Glasses

• Torque Wrench

• Standard Open-End Combo

Wrenches

• Ratchet

• Metric and Standard Sockets

• 7⁄32" Allen Wrench (socket if available)

• 5⁄16" Drill Bit (very sharp)

• Heavy Duty Drill

• Hose Cutter, Razor Blade or

Sharp Knife

• Air Compressor or Compressed

Air Source

• Spray Bottle with Dish Soap & Water

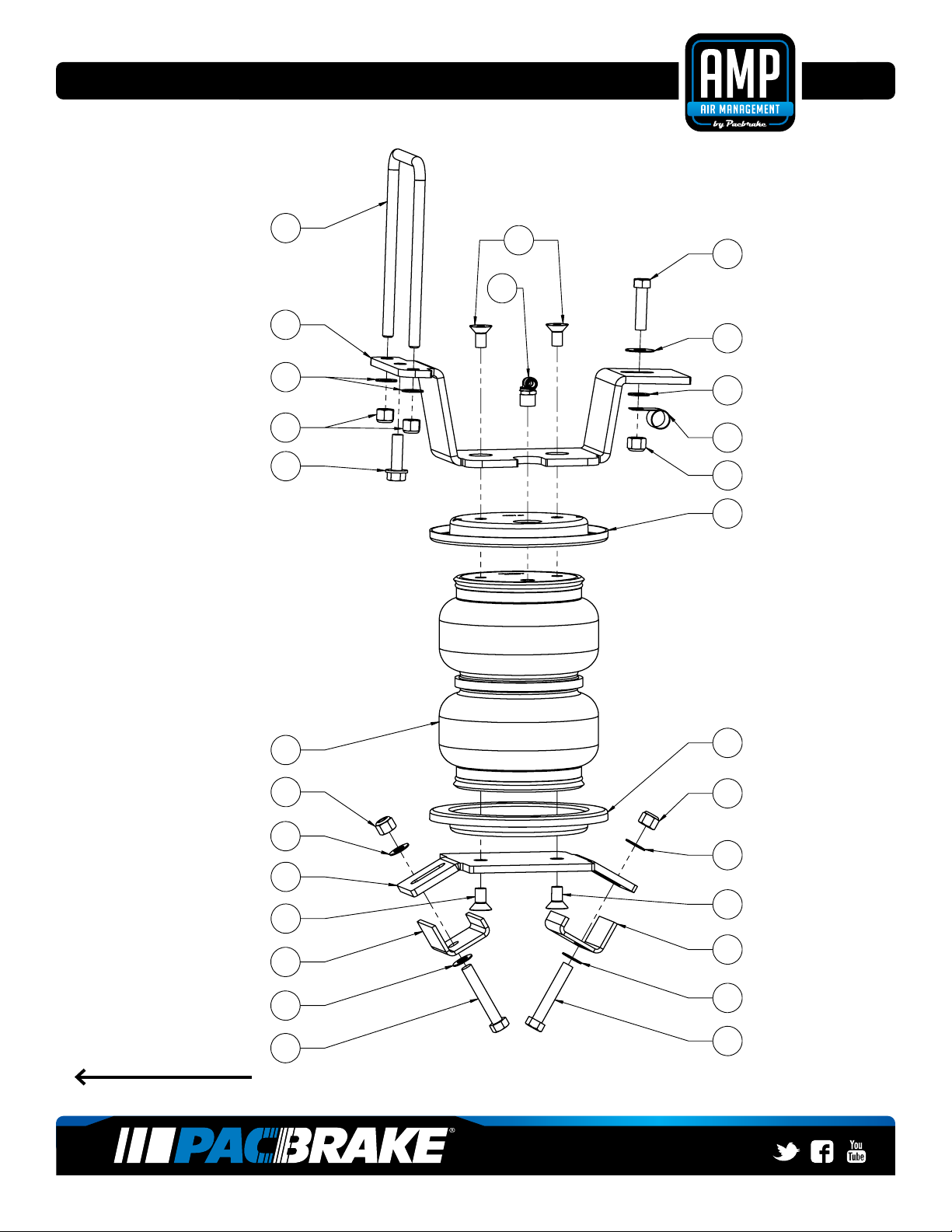

Make sure all the items shown in

the photo are provided in your kit

before starting the installation.

KIT CONTENTS

A Air Spring (2) HP10000D

B Upper Bracket Driver Side (1) HP1432

C Upper Bracket Passenger Side (1) HP1431

D Lower Bracket (2) HP1433

E J Clamp (4) HP1434

F SUB GROUP (1) HP10217

F1 Capscrew, Countersunk (8) HP1008

F2 Bolt 3⁄8x 1 ½ NC (2) C18018

F3 Flat Washer 3⁄8" (2) C18006

F4 Flat washer 3⁄8" SAE (14) C653

F6 Screw Hex Cap 3⁄8"-16 (4) HP1416

F7 Nut Nyloc 3⁄8"-16 (10) HP1000

F8 U-Bolt (2) HP1331

F9 Airline Hose Assembly (1) HP1344

F10 Bolt, Self-Tapping 3 (2) HP1078

F11 Cable Clamp 5⁄8" (2) HP1435

F12 Cable Clamp 1" (1) HP1436

F14 Bolt Leader Tool (1) Hp1440

F15 Heat Shield (1) HP0012

F16 Worm Gear Ring Clamp (2½" - 4 ½") (2) HP1001

F17 Worm Gear Ring Clamp (4½" - 6½") (2) HP1377

H AIR SPRING SUB GROUP (1) HP10180

H1 Fitting, Brass, Push (2) HP1099

H2 Tywrap (6) C11618

H3 Roll Plate (4) HP10054

A

B

C

E

D

D

F12

F11

F2

F10

F6

F17

F16

H15

F14

H1

H2

H3

F9

F8

F7F4

F3

F1