Pacbrake is a registered trademark of Pacbrake Co. 7

HP10121 AMP AIR SUSPENSION KIT L5934

L5934.REV10_16.07.2018

18 AIRLINE INSTALLATION

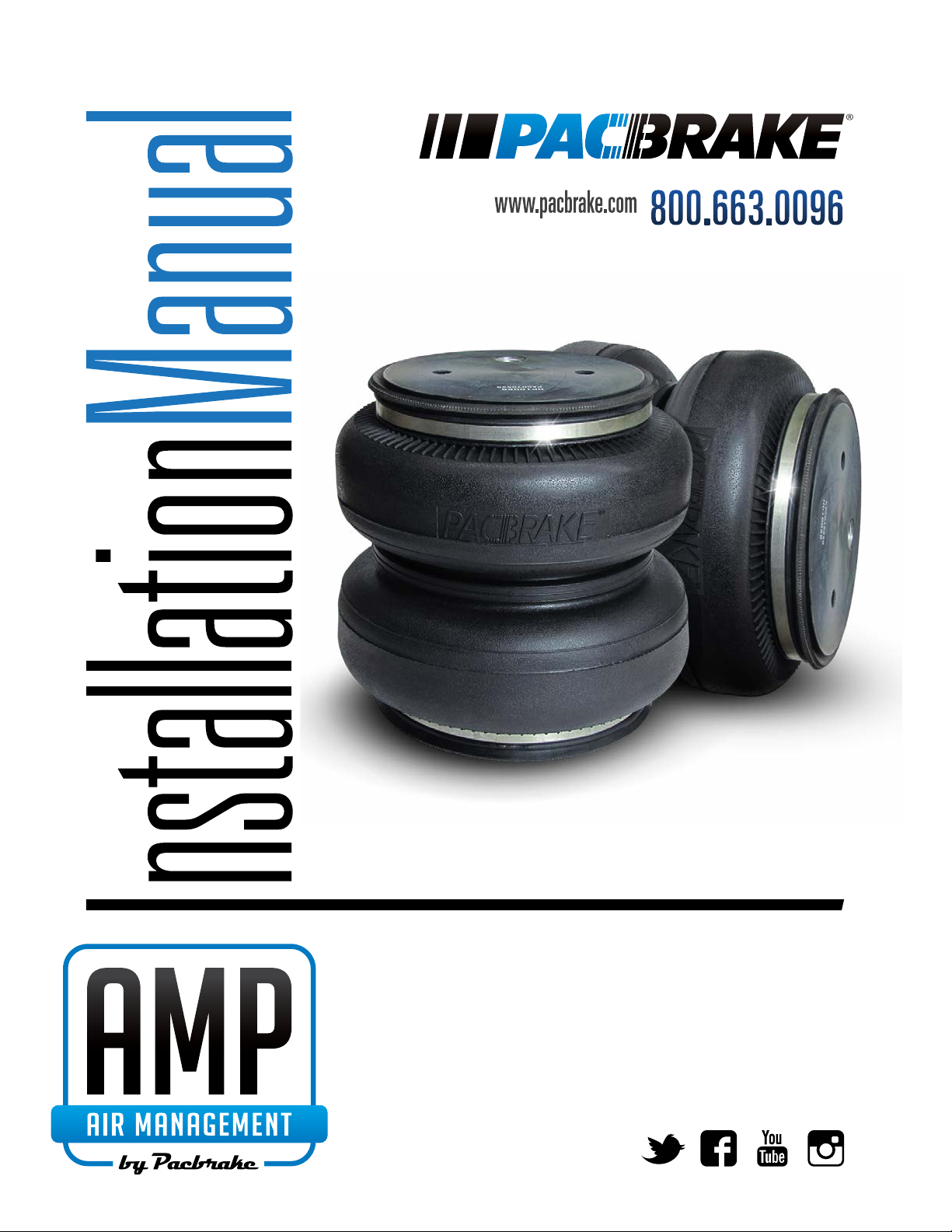

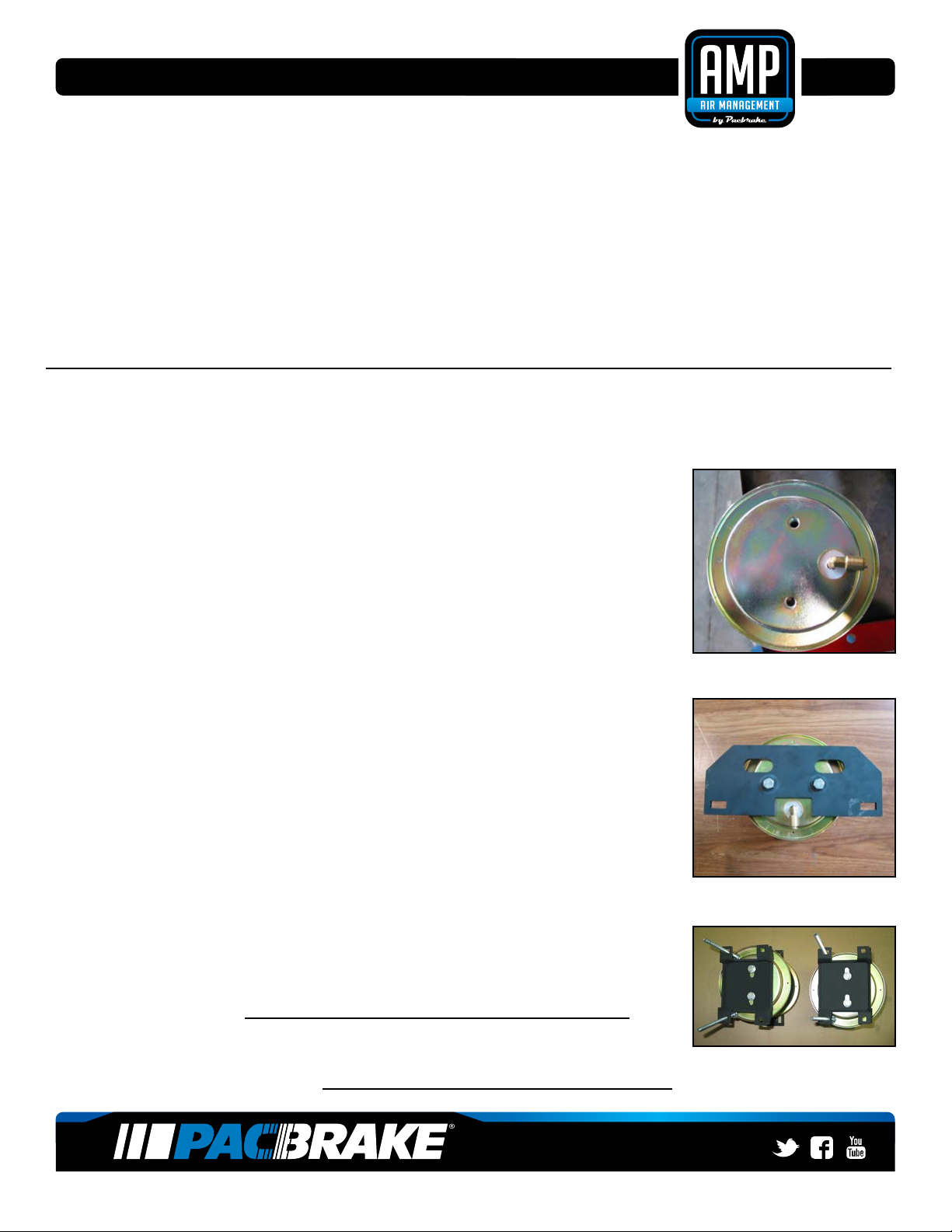

Provided in the basic air spring kit are two ll valves, the most common place to

install them is to replace the license plate fasteners with the ll valves. Alternatively,

two holes can be drilled in a convenient location. Install one airline provided, route

the nylon hose to an air spring tting, cut the hose and connect to the air spring

tting. Repeat with the other ll valve. Secure airlines with the tie-straps provided

away from moving items and heat sources.

If an in cab ination kit is being installed, follow the instructions provided with it.

NOTE: This kit contains push to connect ttings, using scissors or wire cutters to cut the nylon airline will distort the

line and cause the connection to leak. THE AIRLINE MUST BE CUT OFF SQUARELY WITH A SHARP RAZOR

KNIFE. Moisten the end of the airline prior to inserting it into the tting and push it in until it stops.

IMPORTANT!

Double check all the fasteners are torques to specication

19 LEAK CHECK

Inate both the air springs to 90 PSI. Use a dish soap and water mixture on all

airline connections to detect air leaks. Repair as necessary and retest. Inate

your air springs to a pre-determined value, then the following day recheck the

pressure. If one or both the air springs have lost pressure, a leak is present.

The leak must be repaired, then retest until no leaks exist.

SPECIAL NOTE:

Retorque all the fasteners after the rst 500 miles of driving.

OPTIONAL ACCESSORIES

Pacbrake offers an optional dual needle air gauge to monitor the pressure in each air spring from the vehicles

cab. Pacbrake offers a full line of air compressors, air tanks and solenoids to control your air spring system.

OPERATING YOUR VEHICLE WITH PACBRAKE AIR SUSPENSION

Air springs have minimum and maximum pressure requirements, never operate your vehicle with less then

10 PSI in the air spring and never inate the air springs over 100 PSI, damage to the air springs will result.

Check the air pressure in the air springs daily for the rst couple of days to ensure a leak does not develop.

The air springs are designed to maintain the vehicles stock ride height with a load. Do not use the air springs

as a means to lift the vehicle with no load, a rough ride will result.

SERVICING YOUR VEHICLE WITH PACBRAKE AIR SUSPENSION

When lifting the vehicle with a oor jack or hoist on the frame never allow the air spring to limit the travel of the

axle, try to always jack the vehicle on the axle. Suspending the axle with the air spring limiting the axle travel will

damage the air spring and void the air spring warranty.

WARRANTY

To be eligible for warranty, owner must submit their warranty card or register online within 30 days of purchase

date. NOTE: The owners warranty will be void if air springs run with less than the minimum of 10PSI

STEP 18

STEP 19