Site Layout Considerations 2.1

There are several aspects to locating the EVSE equipment at a macroscopic scale that improve

performance, lifetime, and ease of operation. These items are very dependent on the end user's

site and intended use, so they are covered as concept considerations in this section.

•The access of the installation site shall be of sufficient size to allow the transport packages for

the EVSE equipment to pass. If the access doors/gates/corridors are too small for the safe

transport of the transport packages, special provisions may need to be made to allow

installation. The maximum size of the EVSE package is 920x1170x2430 mm (LxWxH). Note:

These details are for each cabinet.

•For locations where the EVSE is exposed to direct sunlight and high ambient temperatures for

most of the day, it is required to install protection from direct sunlight or place the EVSE under

shade.

•For locations where the EVSE is exposed to the possibility for collisions with vehicles, it is highly

recommended to install collision prevention equipment. This may be in the form of bollards or a

significantly raised curb/EVSE footing.

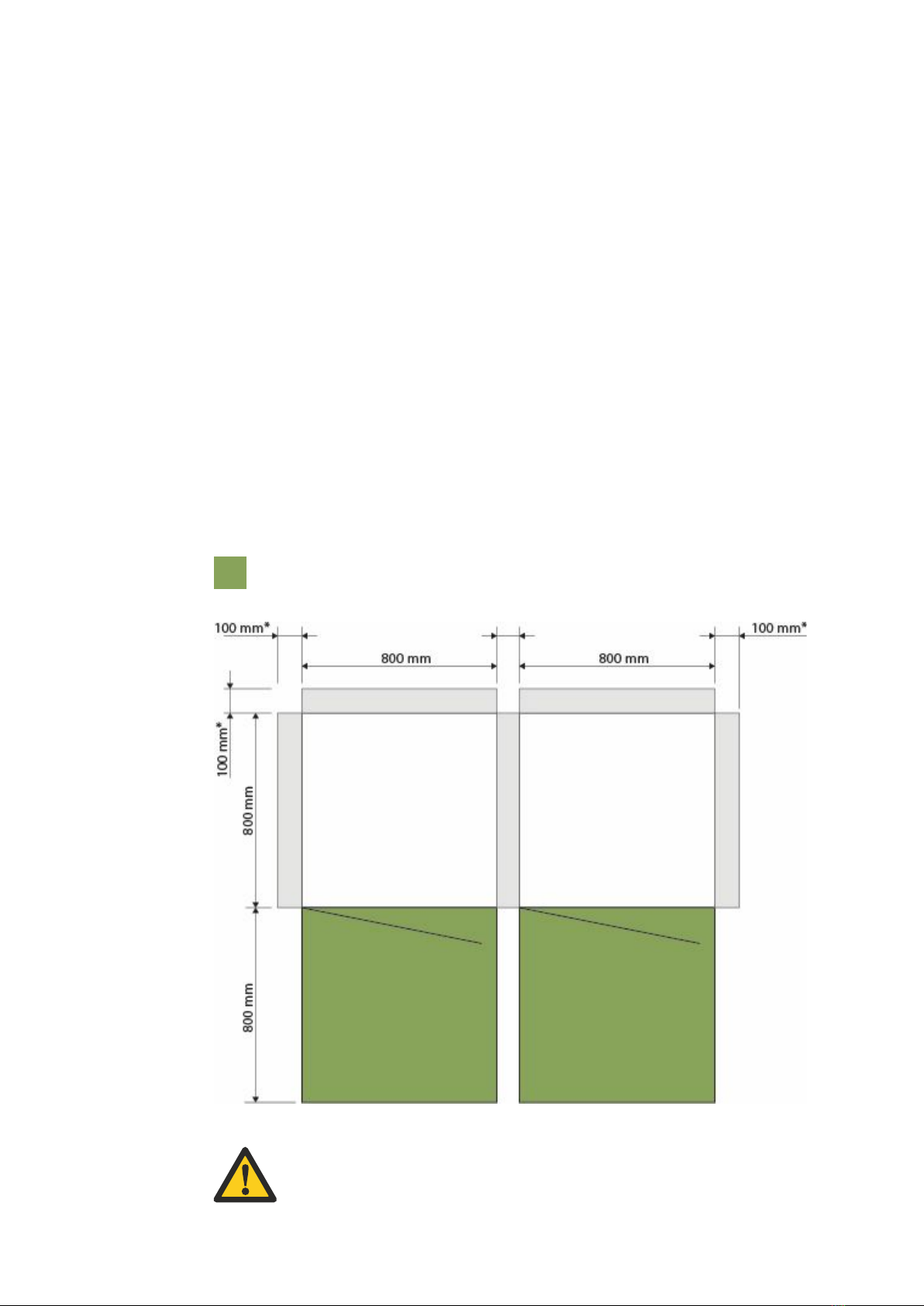

•For locations with significant snow accumulation or snow drifts, it's recommended to install

barriers or a shelter to protect snow from blocking air intake vents. Airflow needs should be

respected in all installations. The EVSE is air cooled by a set of internal fans which take in the

air from the ventilation grids in the bottom of the charger cabinet and release the warm air from

the ventilation grids in the top of the charger cabinet. The air intake has filters to prevent

contamination of the internal side of the charger cabinet. Keep the ventilation grids free from

debris and obstacles to allow for a free flow of air.

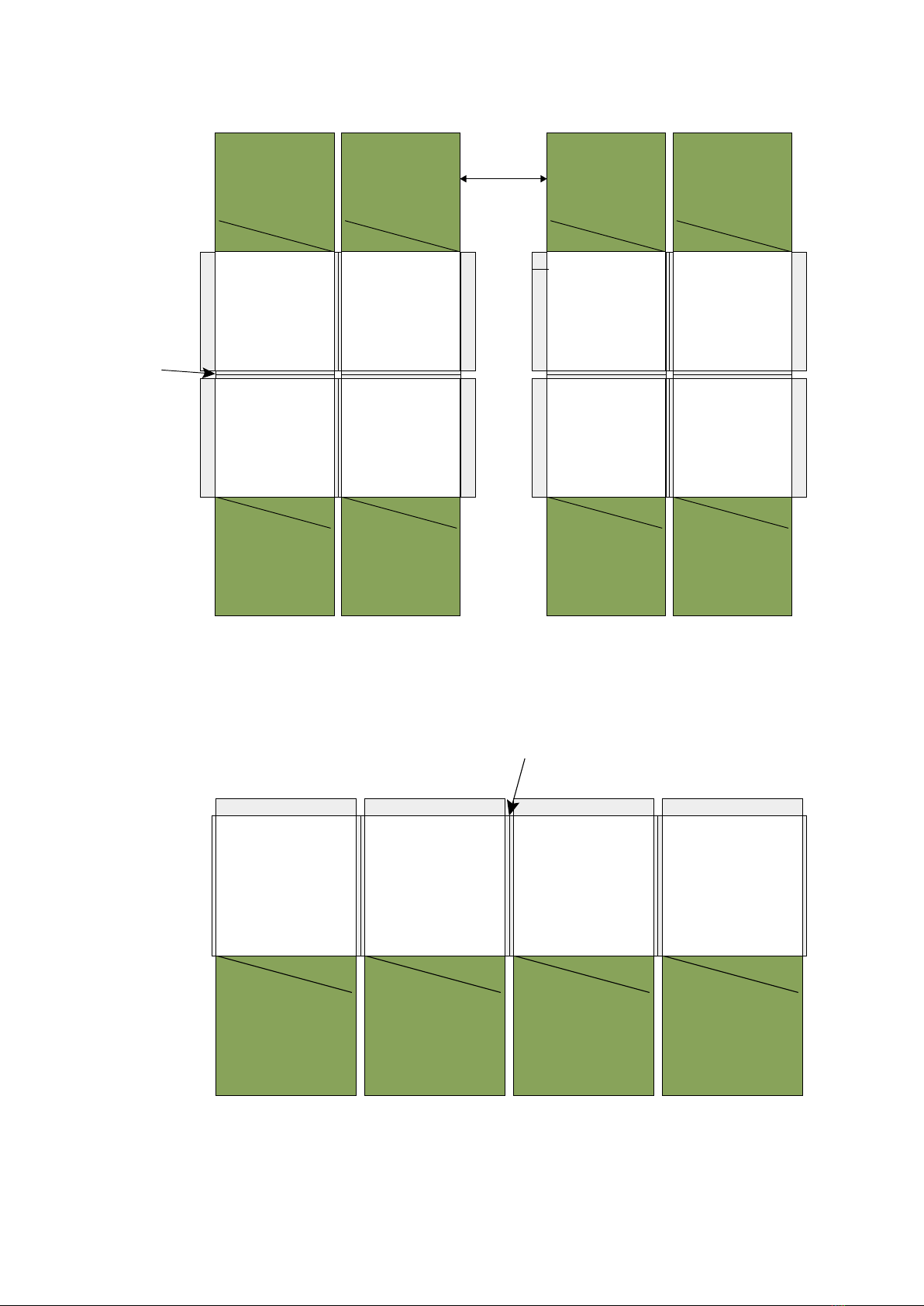

•The maintenance tasks for the EVSE are done from the top and the front of the charger

cabinet. Consider this when spacing units and planning service with vehicles present.

•The operation area is at the front of the charger cabinet. Normally, the charging process is

started, monitored, and stopped automatically by the EV. In case of abnormal operation, it is

possible to stop the charging process with the Charge abort button or the emergency stop

button.

•The escape routes are very location specific and shall comply with the national and local rules

and regulations. Keep in mind that a safe escape route is provided during the maintenance

tasks (with the door open).

•The base unit can supply from 1 to 3 external DC outlets. Even if these are not initially all

deployed, reservation of space is prudent to allow future expansion.

6