Tool Operation and Use Guide

2

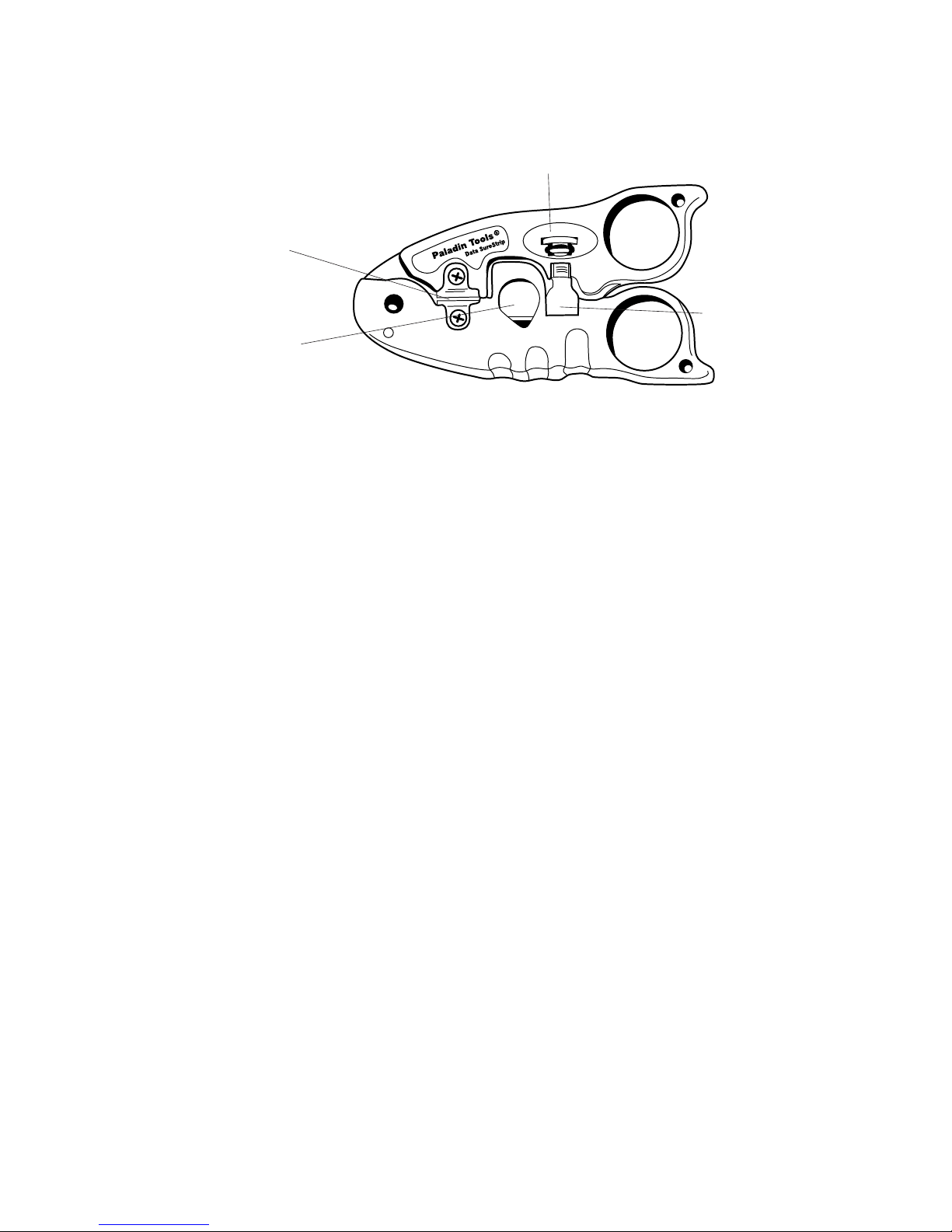

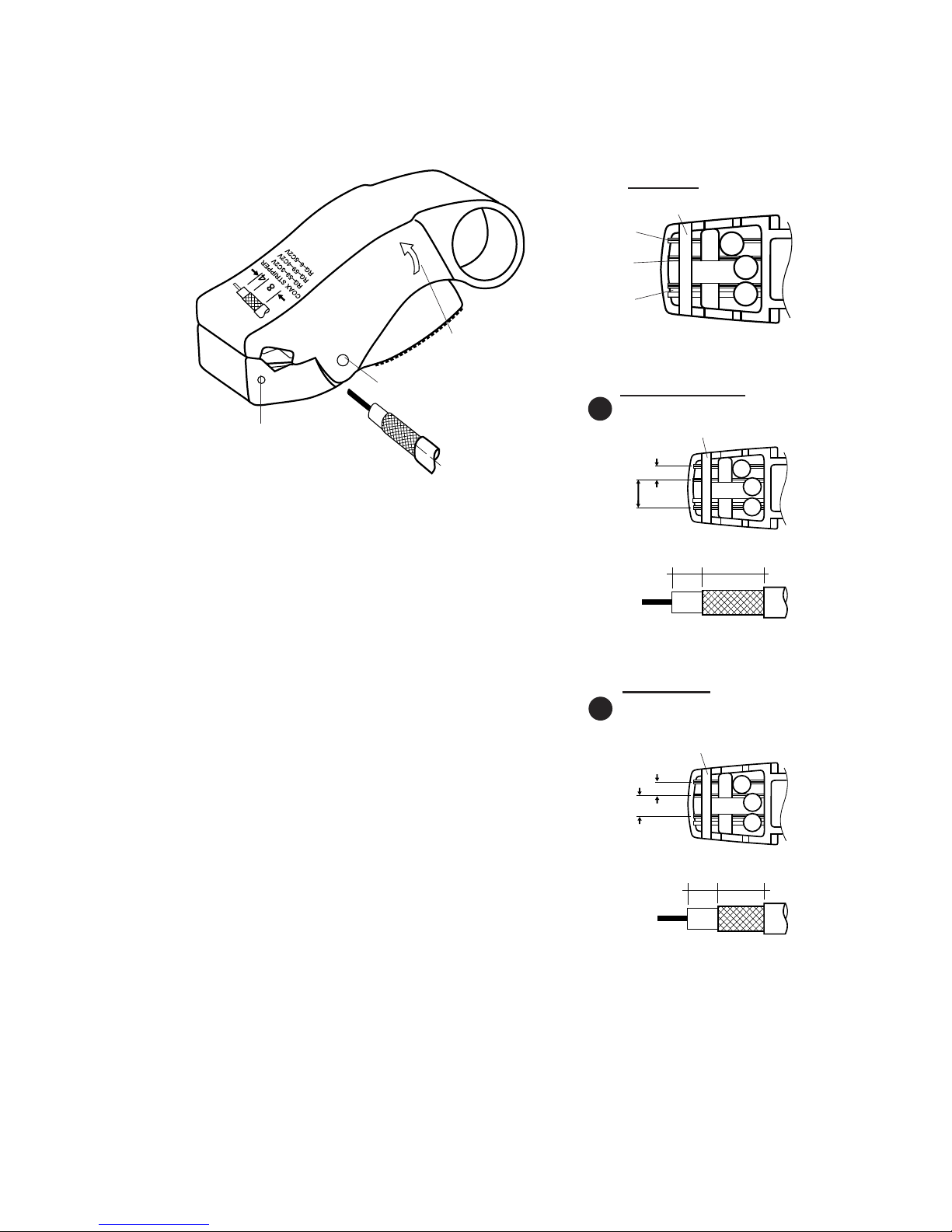

Blade Depth Adjustment Screw

Round Cable

Stripper

Cable

Cutter

1116Data SureStrip™ Twisted Pair

Cable Stripper

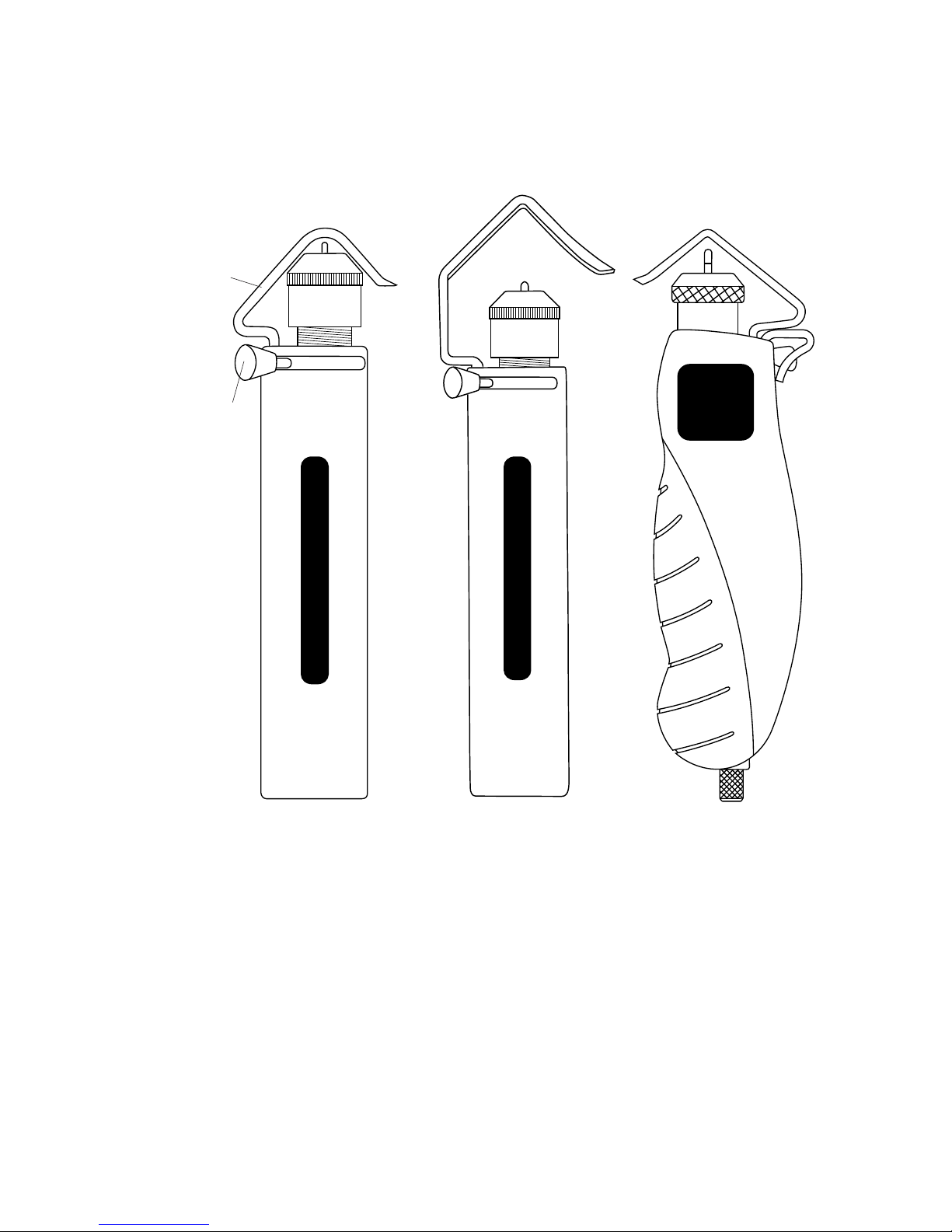

To cut wire & cable:

1. Install the wire or cable into the cable cutter section.

2. Grip the tool & squeeze the top handle down until

the article is cut.

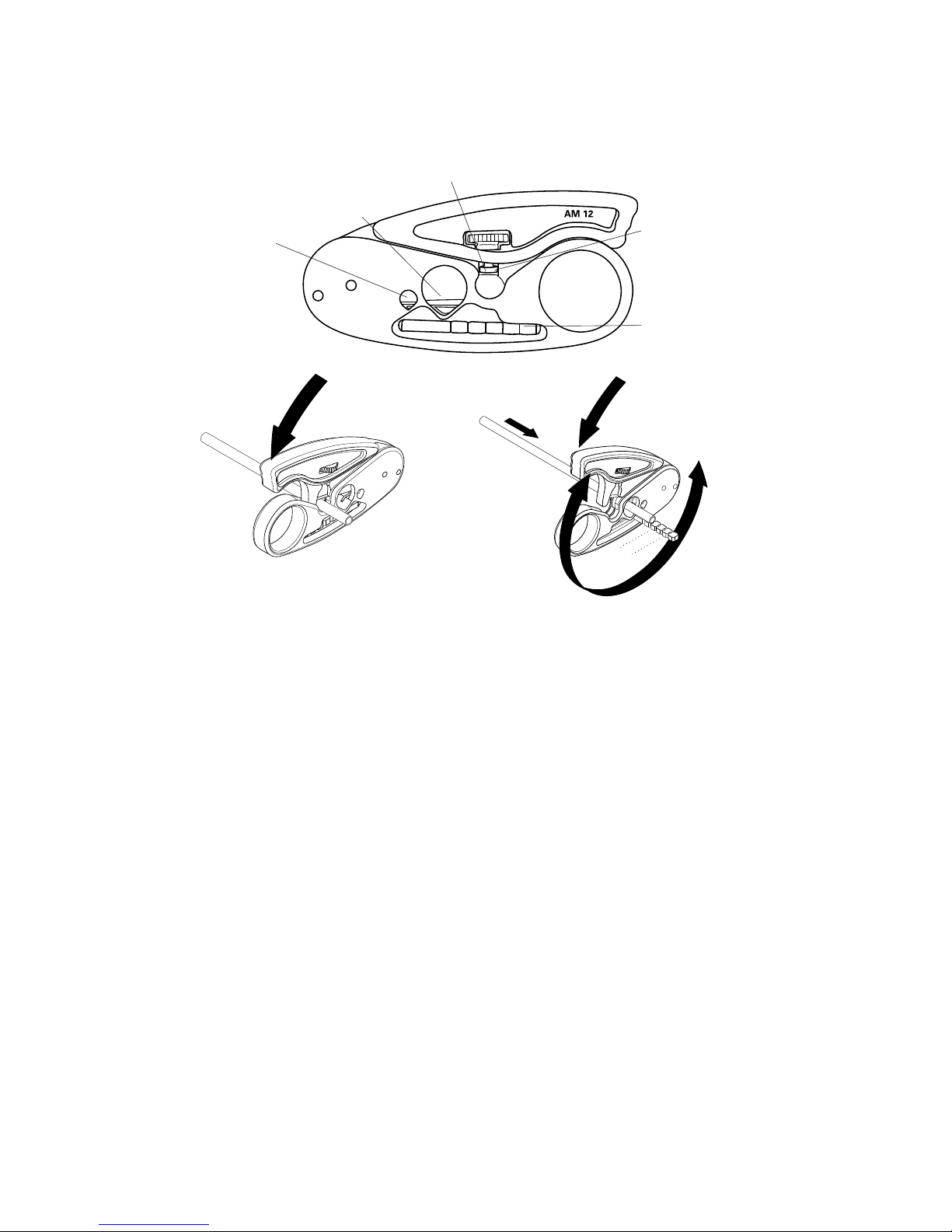

To strip round wire & cable:

1. Adjust the blade depth screw to set the blade cut

depth to desired level to ensure a non-scoring strip.

This may take several test settings before achieving

optimum depth.

2. Place wire/cable into the center round hole of the

tool.

3. Place your finger into the finger loop & spin the

tool clockwise around the cable 3 to 6 times. Do

not press down on the top lever. The tool has a

self-regulating spring to control stripping.

4. Open the tool & remove the cable. Pull the stripped

insulation off the cable.

To strip lat satin telephone cable:

1. Place cable into the flat cable stripper area located

at the front of the tool.

2. Close the tool & hold tool in palm or one hand, &

hold the cable steady in other hand.

3. Using a straight, no-angled motion, pull the tool

away & off from the end of the cable. This will strip

off the outer jacket exposing the inner conductors.

Perfect for 25-Pair!

Flat Cable

Stripper