7.2 Element replacement (UE210 Series): Remove filter

element (8), if already fitted, and carefully inspect the

interior surface (flow through the element is in-to-out) for

visible contamination. Normally no dirt should show,but

visible dirt or particles can be an early warning of system

component failure. Discard both the filter element and its

O-ring. The filter element is NOT CLEANABLE. Any

attempt to clean the filter element can cause degradation

of the filter medium and allow contaminated fluid to pass

through the filter element.

7.3 DO NOT run the system without a filter element

installed. For UH210C series: check that the O-ring

(4) between the cover (3) and tube (2) is not damaged.

For UH210H series: check that the O-ring (5) between

the tube (2) and head (1) is not damaged.

Use the replacement filter as indicated by the part

number on the element endcap.

7.4 Lubricate element O-ring with clean system fluid.

Reinstall element in the shell assembly. Lightly lubricate

cover-to-head or tube-to-head (as applicable) O-ring with

clean system fluid and reassemble the housing until thread

bottoms. The cover or tube should be torque tightened

using a suitable socket wrench to 77 ft/lb or 105Nm.

O-ring sealing is not improved by over tightening

7.5 Bleed the filter by filling the filter until all air bleeds through

the vent plug (7), then torque tighten the vent plug to 12

lb/ft or 16Nm. Check for leaks as per section 4.8.

7.6 After element change ENSURE DIFFERENTIAL

PRESSURE DEVICE IS RESET . Brass visual and

electrical and stainless steel electrical switches reset

automatically. When system reaches normal operating

temperature, check that the electrical switch and/or

visual indicator has not actuated. If visual indicator

actuates due to a cold start condition, reset again as

per section 6.

8 Warranty, Limitation of Liability and

Remedies

THERE IS NO WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE WITH RESPECT

TO ANY OF THE PRODUCTS, NOR IS THERE ANY OTHER

WARRANTY EXPRESS OR IMPLIED, EXCEPT AS PROVIDED

FOR HEREIN.

For a period of twelve months from the date of delivery from

Seller or three thousand hours of use, whichever occurs first (the

“Warranty Period”), Seller warrants that products manufactured

by Seller when properly installed and maintained, and operated

at ratings, specifications and design conditions, will be free from

defects in material and workmanship. By way of explanation and

not limitation, the Seller does not warrant the service life of the

filter element as this is beyond the Seller’s control and depends

upon the condition of the system into which the filter is installed.

4

7 Filter element installation / servicing

During servicing, the external surfaces of the filter assembly

must be cleaned to remove any dust deposits.

Servicing must be conducted using suitable tools that do not

present a hazard.

Servicing must not be carried out when a potentially explosive

atmosphere is present.

Refer to Service Parts List (Section 9) for item numbers for

applicable replacement element series. Remove and replace

element as follows:

7.1 Turn off and depressurize the system.

7.1.1 For UH210 series (cover service):

Open the vent plug (7) at the top of the filter one and

one-half turns. Open partially the blanking plug (6b)

in the filter head and drain fluid into a suitable waste

receptacle. This sequence may be long for high viscosity

fluids. Replace and torque tighten the blanking plug to

12ft/lb or 16Nm. Unscrew and remove cover (3) from tube

(2) counter-clockwise when viewed from above. It will be

necessary to use a 1” socket wrench on the hexagon on

the cover (3) to loosen the cover initially

Note: The UH210 series assembly is equipped with Pall’s

‘Auto-Pull’ element extraction mechanism to facilitate element

removal. While removing the cap, tabs on the element endcap

lock into hooks in the cap and the element is automatically

pulled from the nipple.

7.1.2 For UH210H series (head service):

Open the drain plug (7) at the bottom of the bowl

assembly (tube and cover) and drain fluid from the

bowl into a suitable waste receptacle. Replace and

torque tighten drain plug to 12 ft/lb or 16Nm. Unscrew

and remove the bowl assembly (2 and 3) from head (1)

counter-clockwise when viewed from below. It will be

necessary to use a 1” socket wrench on the hexagon on

the cover (3) to loosen the cover initially.

WARNING:

FAILURE TO DEPRESSURISE THE FILTER

BEFORE SERVICING ELEMENT COULD RESULT

IN EXPLOSIVE LOSS OF FLUID, DAMAGE TO

EQUIPMENT AND POSSIBLE PERSONAL INJURY.

WARNING:

DO NOT ATTEMPT TO CLEAN OR RE-USE THE

ELEMENT.

ONLY USE GENUINE PALL REPLACEMENT FILTER

ELEMENTS. USE OF SUBSTITUTE ELEMENTS MAY

INVALIDATE PRODUCT WARRANTY.

CAUTION:

Filter elements should be replaced upon indication or at

specified intervals, six months maximum. Failure to change

the element will cause the filter to go on bypass.

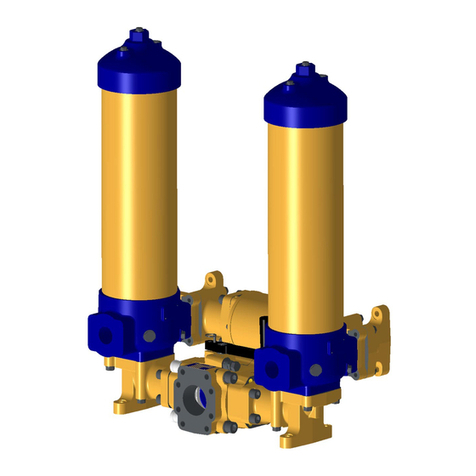

UH210 UH210 Series

HIGH PRESSURE FILTERS service instructions

Figure 1b - Brass Switch Circuit Diagram

COMMON

Pin 1

NORMALLY

CLOSED

(NC) Pin 2

NORMALLY

OPEN (NO)

Pin 3

LOW DIFFERENTIAL PRESSURE

HIGH DIFFERENTIAL PRESSURE

See individual indicator options for connection details.