7

XK130V-POWER

CONNECTION/DISCONNECT & OPEARTION

The connection, disconnection and grounding is carried out through the plug on the machine. For

safety reasons do not change this plug in any situation. For the protection control device, we

recommend that the operator should supply a fuse with current ratings and the total length

between the fuse and connection terminal should coincide with the following “ Extension lead

Chart”

Amperage Rating 3A 6A 10A 13A

Extension Cable Length Wire Size mm2

0.75m 0.75 0.75 1.0 1.25

15m 0.75 0.75 1.0 1.5

22.5m 0.75 0.75 1.0 1.5

30m 0.75 0.75 1.0 1.5

45.5m 0.75 1.25 1.5 2.5

The power source for this machine is 220V. Make sure that the Emergency stop switch is in the off

position before plugging the cord in. Disconnect the machine from the power source with the plug

before servicing and when changing accessories.

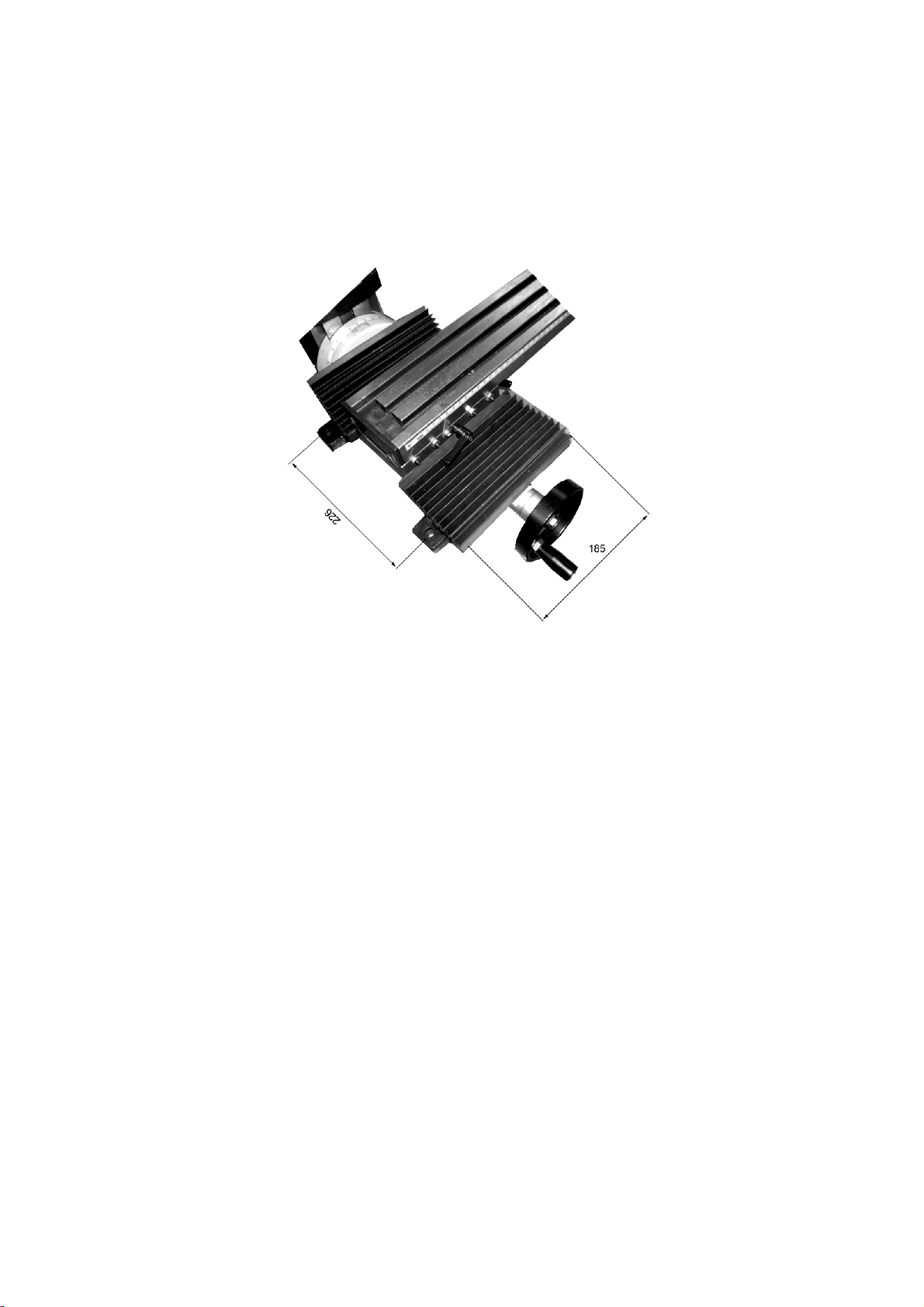

XK130V – MACHINE INSTALLATION

MACHINE LOCATION & SET UP

The machine should be fixed on the working table with four hexagon holts. Please install it to an

appropriate location in order to meet with the precision requirements of the machine. Before

setting your machine up, clean off any anti-rust protector and grease that was used for shipping

purposes. You can use a clean cloth and appropriate solvents.

(1) When selecting a location make sure that your worktable has a flat surface.

(2) Avoid placing in a location with exposure to direct sunlight, heavy moisture and excessive dust.

(3) When you have found your desired location, drill 4 locating holes on the worktable, the

dimensions should be the same as the machine base.