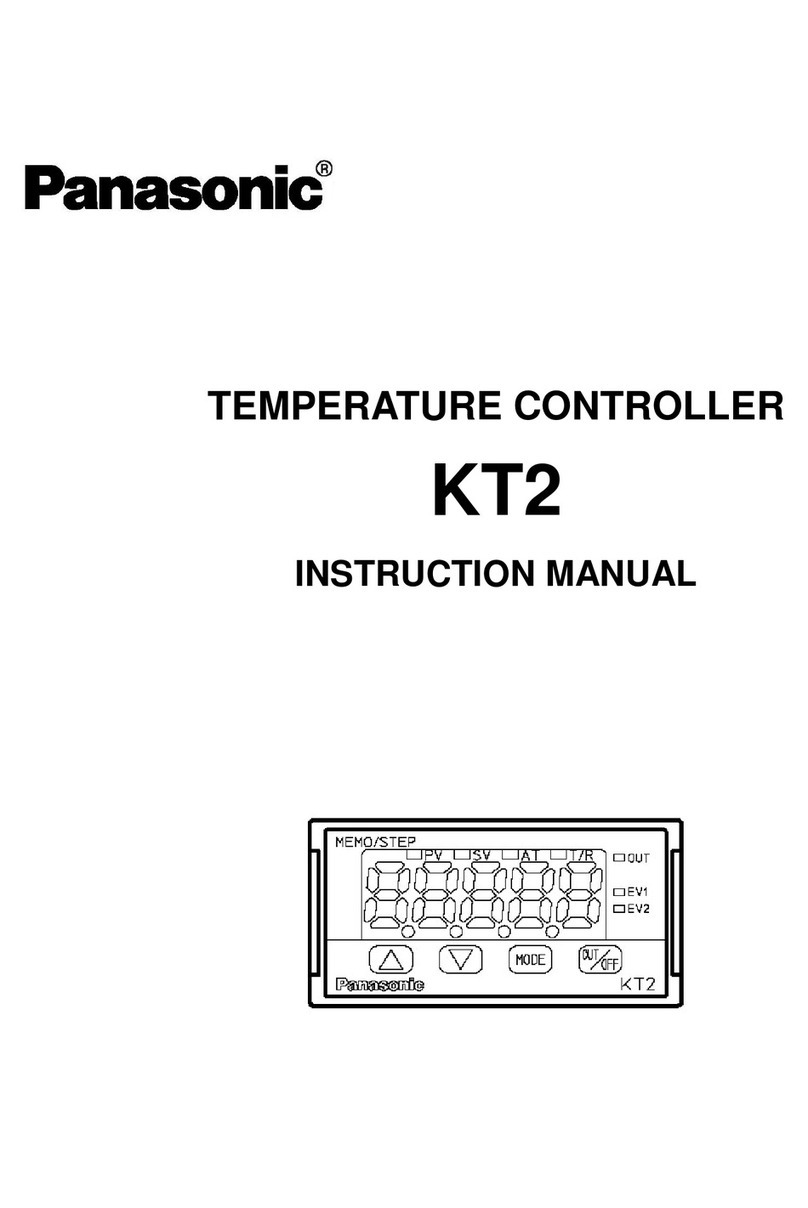

9

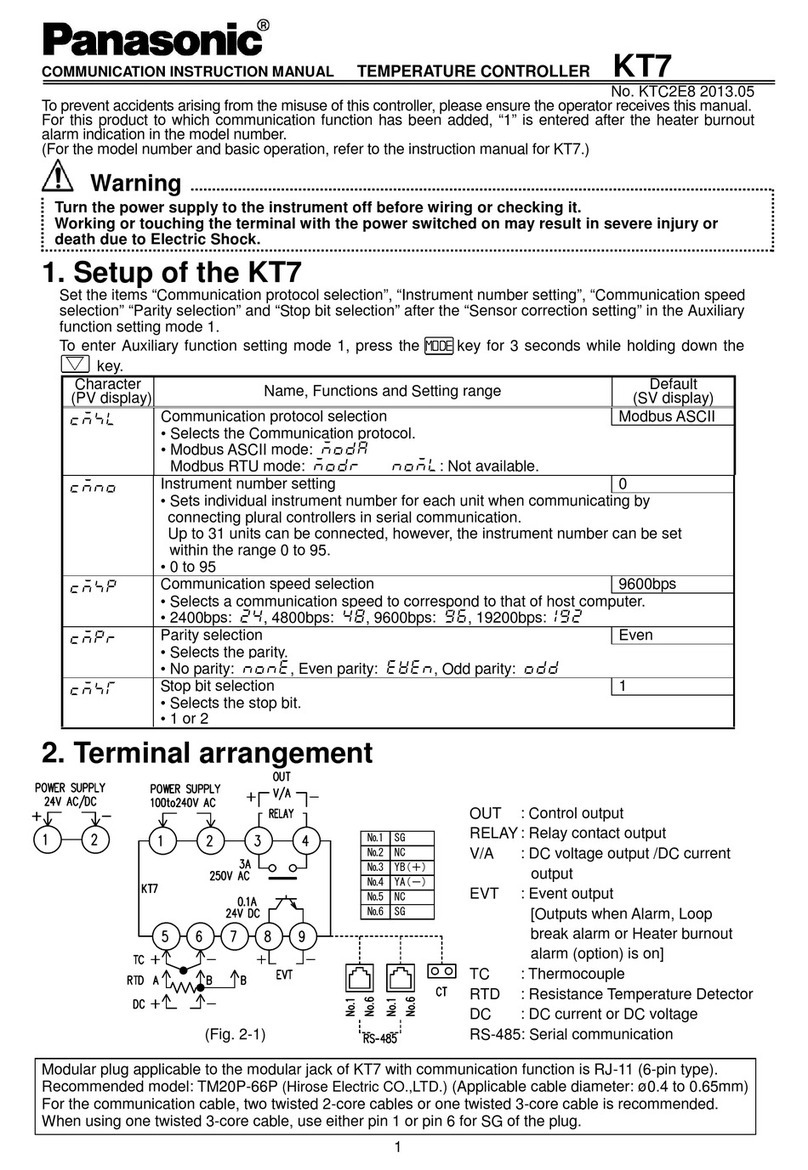

• Response message from the slave in exception (error) status (When a value out of the setting range is set)

The function code MSB is set to 1 for the response message in exception (error) status (86H).

If an exception code (03H: Value out of the setting range) is returned, the error can be determined by

reading this code.

(Fig. 6.4-10)

7. Communication command table

Modbus

function code Data item Data

03H/06H 1110H: Step 1 SV Set value, Decimal point ignored

03H/06H 1111H: Step 1 time Set value, Decimal point ignored

03H/06H 1120H: Step 2 SV Set value, Decimal point ignored

03H/06H 1121H: Step 2 time Set value, Decimal point ignored

03H/06H 1130H: Step 3 SV Set value, Decimal point ignored

03H/06H 1131H: Step 3 time Set value, Decimal point ignored

03H/06H 1140H: Step 4 SV Set value, Decimal point ignored

03H/06H 1141H: Step 4 time Set value, Decimal point ignored

03H/06H 1150H: Step 5 SV Set value, Decimal point ignored

03H/06H 1151H: Step 5 time Set value, Decimal point ignored

03H/06H 1160H: Step 6 SV Set value, Decimal point ignored

03H/06H 1161H: Step 6 time Set value, Decimal point ignored

03H/06H 1170H: Step 7 SV Set value, Decimal point ignored

03H/06H 1171H: Step 7 time Set value, Decimal point ignored

03H/06H 1180H: Step 8 SV Set value, Decimal point ignored

03H/06H 1181H: Step 8 time Set value, Decimal point ignored

03H/06H 1190H: Step 9 SV Set value, Decimal point ignored

03H/06H 1191H: Step 9 time Set value, Decimal point ignored

03H/06H 0001H: SV1 Set value, Decimal point ignored

0002H: Not used

03H/06H 0003H: AT 0000H: Cancel 0001H: Perform

03H/06H 0004H: OUT1 (Heating) proportional band Set value, Decimal point ignored

03H/06H 0005H: OUT2 (Cooling) proportional band Set value, Decimal point ignored

03H/06H 0006H: OUT1 (Heating) integral time Set value

03H/06H 0007H: OUT1 (Heating) derivative time Set value

03H/06H 0008H: OUT1 (Heating) proportional cycle Set value

03H/06H 0009H: OUT2 (Cooling) proportional cycle Set value

03H/06H 000AH: Manual reset Set value, Decimal point ignored

03H/06H 000BH: A1 value Set value, Decimal point ignored

03H/06H 000CH: A2 value Set value, Decimal point ignored

000DH: Not used

0011H: Not used

03H/06H 0012H: Set value lock (*1) 0000H: Unlock 0001H: Lock 1

0002H: Lock 2 0003H: Lock 3

0013H: Not used

0014H: Not used

03H/06H 0015H: Sensor correction Set value, Decimal point ignored

03H/06H 0016H: Overlap band/Dead band Set value

0017H: Not used

03H/06H 0018H: Scaling high limit Set value, Decimal point ignored

03H/06H 0019H: Scaling low limit Set value, Decimal point ignored

03H/06H 001AH: Decimal point place 0000H: No decimal point

0001H: 1 digit after decimal point

0002H: 2 digits after decimal point

0003H: 3 digits after decimal point

(*1) If Lock 3 is selected, the set data is not saved in the memory. After the power is turned off, the

set value reverts to the value set before Lock 3 was selected.

3.5 idle

characters Slave

address Function

code Exception

code Error check

CRC 3.5 idle

characters

(01H) (86H) (03H) (0261H)

1 1 1 2 Number of