- 2 -

ZVP-PC-0069-00-R1

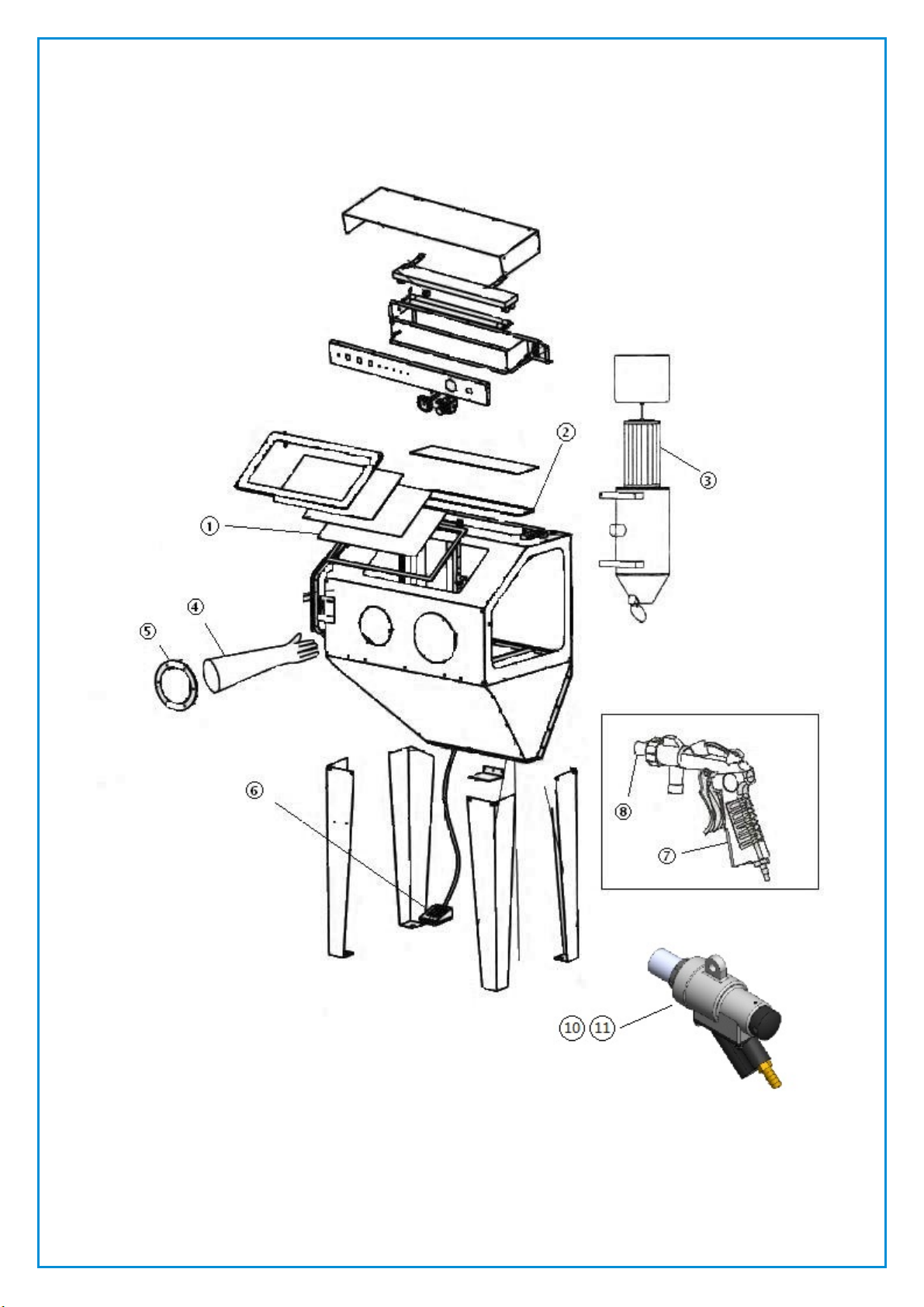

switch on the right side. Secure the assembly in

position using four (4) of the 1/4" x 3/4" bolts

and nuts provided.

2.11 Attach the dust collector body to the rear panel

(right side) aligning the intake tube with the rear

panel hole. Fix in position using four (4) of the

1/4" x 3/4" bolts provided.

2.12 Place the dust collector motor and filter

assembly into the top of the dust collector body

and lock in position using the 2 latches

provided.

2.13 Remove the inlet box that covers the dust

collector intake tube hole from the rear panel of

the cabinet. Apply a bead caulking around the

tube to seal it, then fit sponge filter media into

box (to protect fan motor from dust) and refit

the inlet box.

2.14 Place the cabinet floor grate into the cabinet

ensuring the corner cut out is located in the

right hand front corner of the cabinet to allow

the suction gun hoses to pass through.

2.15 Check that all securing nuts, bolts and screws

are correctly tightened.

2.16 Connect the dust collector plug into the female

socket coming from the light assembly, and

then connect the plug from the light assembly

into the power supply socket.

2.17 Take the self-locking air connection fitting from

the inner packing. Wrap a thread sealing tape

round the fitting thread. Screw it into the air

inlet hole on the rear side of the electrical

control box and tighten.

2.18 Push the coupler to the self-locking fitting

toward the air inlet hole, the cone shaped end of

the connector will immediately pop out. Fit it

into the air hose connecting to the air

compressor, fasten with a hose clamp. Push the

coupler again and fit in the opposite side of the

cone shaped end, release and the connection is

secure.

2.19 Remove the suction head from the fixed gun

assembly, fit in the air jet, re-connect the

suction head and tighten. Loosen the M6 screw

on the side of the gun and install the

corresponding blast nozzle (orifice size should

be twice the size of the air jet), tighten the

screw.

2.20 Connect the side branch of the gun assembly

with a suction hose. Connect the rear inlet of

the gun to the flexible metal hose in the cabinet,

screw until secure.

2.21 Connect the other end of the suction hose to

the corresponding suction pipe.

2.22 Connect one end of the high pressure air hose

to the air connector on the right side of the

electrical control box, the other end to the air

inlet on the movable gun, secure with hose

clamps.

2.23 Connect one end of the suction hose to the side

branch of the movable gun assembly, the other

to the fixed suction pipe.

2.24 Installation of the air jet and nozzle are the

same as the fixed gun assembly.

3.0 OPERATING INSTRUCTIONS

3.1 Cabinet operation

3.1.1 Assemble and install the blast cabinet as

detailed in Section 2.0 of this manual.

3.1.2 The air jet should be approximately half the size

of the nozzle.

3.1.3 Pour abrasive media approximately 18 kg (40lb)

into the cabinet hopper through the side door of

the cabinet.

3.1.4 Turn on the compressed air supply, when the air

pressure reaches 415 Kpa (60 PSI), press the

power switch to “ON”, the power indicator

should then light up.

! WARNING ! – NEVER EXCEED MAXIMUM

OPERATING PRESSURE OF 125PSI (8.6BAR), AS

THIS MAY RESULT IN SERIOUS INJURY OR

DEATH.

3.1.5 The machine comes with two (2) blasting guns,

but under the control of an electric/pneumatic

system where only one gun is operable at any

one time. When the movable gun and door

closed indicators on the control panel are

illuminated then the movable gun is available

for operation. Step on the pedal switch and the

movable gun shuts down and the fixed gun

operates immediately, this will be seen on the

control panel indicators.

3.1.6 There are limit switches located inside each

door to sense when the doors are open or

closed. If the door closed indicator on the

control panel is not illuminated, the system is

then in a protection mode and the fixed gun will

not operate.

3.1.7 When the air pressure exceeds 60 PSI, the user

can operate the machine. First insert arms into

the rubber gloves, grasp the work piece to be

blasted, position it under the fixed gun, step on

the pedal switch and then the blasting process

begins. Alternately grasp the movable gun,

point the nozzle at the work piece, press the

trigger and the blasting process begins, check

the work piece to ensure the desired result has

been obtained.

3.1.8 The abrasive media will drop into the bottom of

the cabinet hopper to be recycled during the

blasting process.

NOTE: TO ENSURE RELIABLE BLASTING THE

COMPRESSED AIR SHOULD BE DRY, IF IT

CONTAINS TOO MUCH MOISTURE, A

MOISTURE SEPARATOR SHOULD BE

INSTALLED IMMEDIATELY BEFORE THE AIR

ENTERS THE CONNECTION TO THE CONTROL

BOX.

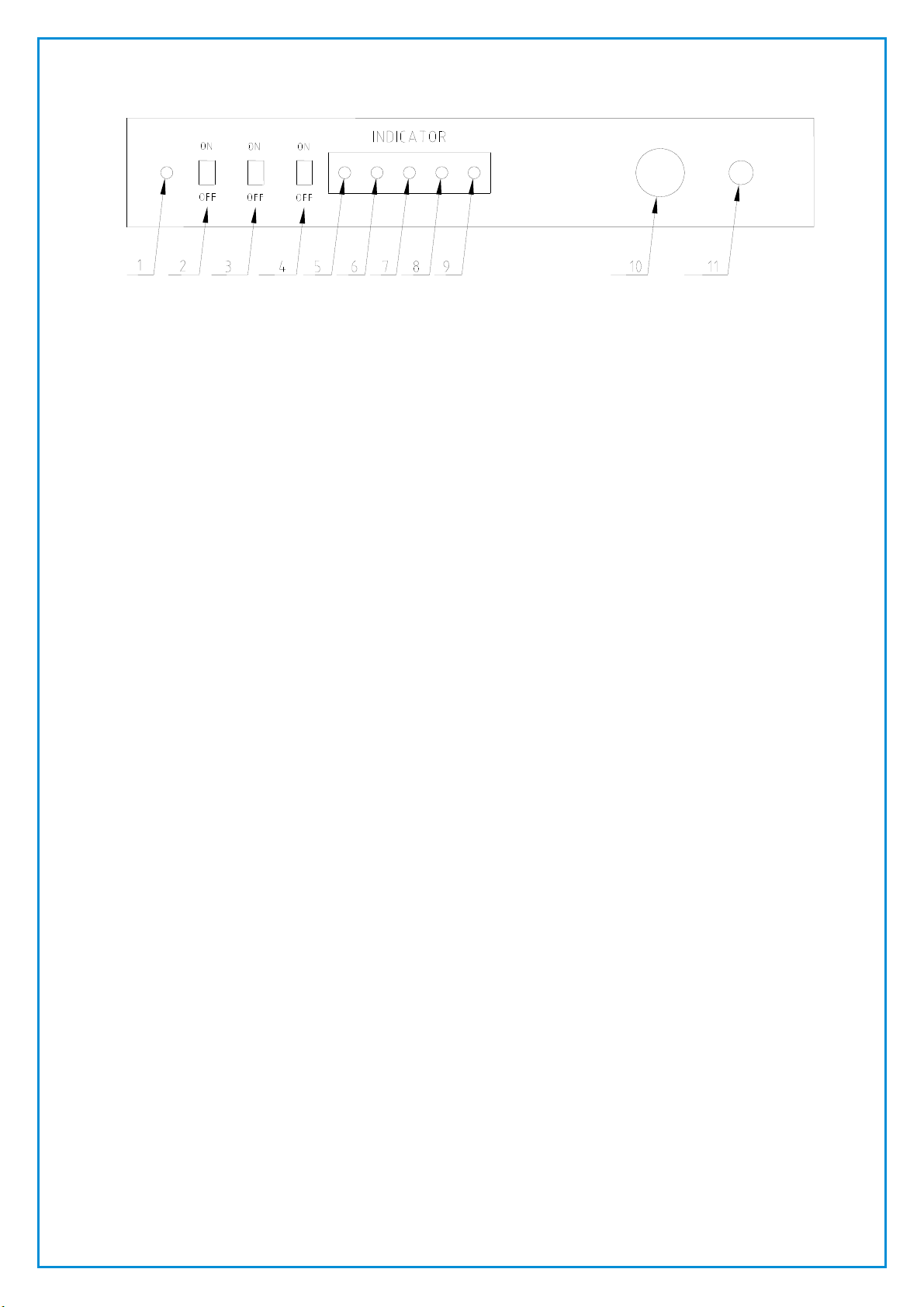

3.2 Illumination and electro-pneumatic system

3.2.1 The pneumatic system is controlled by an

electric circuit, which is set inside the control

box located on top of the cabinet. A layout of

the front panel of the box is shown below in

Figure 1.

3.3 Control panel functions and indicators