EN

- 3 -

This applicance can be used by children aged 8 or over and people with reduced physical, sensory or

mental abilities or lack of experience and knowledge only if they are given appropriate supervision or training

regarding the safe use of the appliance and understand the risks involved. Children must not play with the

appliance. Cleaning and user maintenance must not be performed by children without supervision.

• Remove the packaging immediately when you receive the appliance. Check its general appearance and

in the event that you see any problem inform your dealer or installer immediately.

• Your appliance is intended for normal domestic use. It is not to be used for commercial or industrial

purposes or for any purpose other than those for which it was designed.

• The supplier makes no guarantee as to any consequences and harm arising from incorrect installation or

misuse of the appliance.

• Never attempt to modify the features of this appliance as this represents a risk. Repairs must be carried

out exclusively by an authorised specialist technical service. To avoid risks, all tampering with the appliance

is prohibited, including replacing the power cable.

• If the hood is not fitted with a power cable and a plug, or some other means of disconnecting it from the

mains power supply featuring a contact gap in all poles to assure total disconnection under the conditions

provided for by overvoltage class III, it must be equipped with means of disconnection from the fixed

installation in accordance with installation regulations (omnipolar circuit breakers connected directly to the

power terminals, which must have a contact gap in the poles to cut off the electrical power supply in the

event of class III overvoltage).

• It must be possible to disconnect the device from the power supply after installation. This can be done by

making the plug accessible or by fitting a circuit breaker in the electrical installation in accordance with the

rules for the installation.

• If the power cable is damaged, it must be replaced by the manufacturer, its after-sales service or similar

qualified staff in order to avoid any danger.

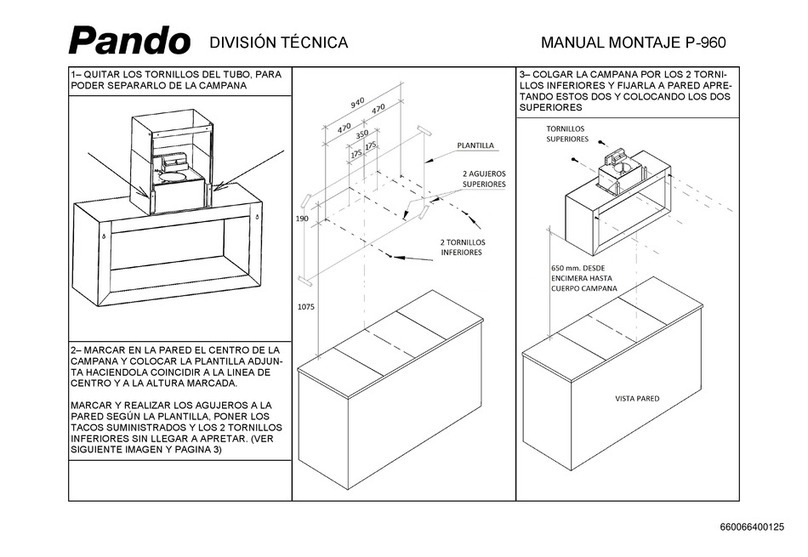

• Special care must be taken when drilling into walls or ceilings to ensure there are no concealed electrical

cables, pipes, metal girders, etc. as drilling into them can cause serious damage, divert electrical current

or transmit noise and vibration.

• IMPORTANT: For installation, always switch off the power supply at the appropriate differential or

circuit breaker in the main house fuse box before making the electrical connection for the appliance.

• WARNING: Always disconnect the hood from the power supply by unplugging it or using the

appropriate differential or circuit breaker in the main house fuse box before beginning cleaning or

maintenance work. Never use steam or high-pressure devices to clean your hood (electrical safety

regulations). See section 5, page 24-29, cleaning and maintenance.

• Never cook foodstuffs directly over the flame or have the gas burners on under the hood without cooking

recipients over them (flames sucked in might damage the appliance and the warranty would be voided). The

appliance is not authorised for use over a solid fuel burner (wood, coal, etc.).

Frying under the hood must be constantly supervised because oils and fats can catch fire at very high

temperatures. Do not flambé food under the hood.

• Caution: risk of burns. Accessible parts of the appliance can heat up when used with cooking equipment.

• The distance between the surface on which the cooking containers stand on the hob and the bottom of

the hood must be at least 65cm if the extractor hood is fitted over a gas cooker. If the gas cooker installation

instructions specify a greater distance, this must be taken into account.

1. SAFETY INSTRUCTIONS