• 3 Holiday Schedules - Each of these 36 holidays can be assigned to one of three holiday

schedules (A,B or C). For example if July 4th is assigned to holiday schedule A, then on July 4th

only those events and sensor events containing holiday A in their day fields will be executed.

• Keyboard Override - Toggles the current output state; begins immediately when initiated and

remains in effect until overridden again or until the next programmed event occurs.

• Astro - Optional Astro feature assignable to any combination of channels. Astro will auto-

matically keep track of the changing sunrise and sunset times throughout the year without

the need of a photocell. The Astro feature will keep assigned output(s) off during daylight

hours.

• Selectable Clock Format - 12 hour (am/pm) or 24 hour clock format.

• Stagger Up - Optional stagger up time between channels, after a power outage; selectable

from 5 seconds, 15 seconds, 30 seconds, 1 minute, 5 minutes, 10 minutes, and 15 minutes.

• Momentary - The EL712 will normally be configured as maintained. The momentary option is

intended for use with latching relays. An EL712 configured as momentary will only have 6

channels. Relays 1, 3, 5, 7, 9 and 11 will provide a one second ON pulse for channels 1, 2,

3, 4, 5 and 6, respectively. Relays 2, 4, 6, 8, 10 and 12 will provide a one second OFF pulse

for channels 1, 2, 3, 4, 5 and 6, respectively. See example 2 on page 16 for more details.

• Computer Interface - The controls can be programmed and reviewed by a local personal

computer using Pecosoft.EL software (sold separately).

Electrical:

1. Power Requirements -

Input Voltage 24, 120, 208, 240 or 277 Vac, 50/60 Hz

2. Outputs - Twelve SPDT relays with contacts rated as follows:

Normally Open Contacts: 20 amp resistive or inductive at 120-277 Vac

1 HP at 120 Vac

2 HP at 208-277 Vac

5 amp tungsten at 120-240 Vac

20 amp ballast at 120 Vac

10 amp ballast at 208-277 Vac

470 VA at 120-240 Vac

Normally Closed Contacts: 10 amp resistive or inductive at 120-277 Vac

1/4 HP at 120 Vac

1/2 HP at 208-277 Vac

3 amp ballast at 120-277 Vac

275 VA at 120-240 Vac

3. Wiring - Relay contact terminals can accommodate 10-16 AWG

- Power input terminals can accomodate 12-18 AWG

- Sensor/override input terminals can accommodate 18-22 AWG

4. Power Outage Carryover - The program and time of day are maintained during a power

outage for a minimum of 2 days by means of a capacitor. After two days, a lithium battery

takes over and provides a minimum accumulated carryover of 1 year. The lithium battery

should provide over 10 years of carryover protection.

Environmental:

1. Temperature - Operating: -20 F (-29 C) to 140 F (60 C)

2. Relative Humidity - 10 to 90% RH (non-condensing)

3. The EL712 should be mounted indoors in an environment that is free from excessive conta-

minants such as oil, moisture and dirt.

Physical: Enclosure Dimensions

Enclosure: NEMA 1 drawn steel with lockable hasp

W = 14.3" (36.4cm), H = 16.1" (40.9 cm), D = 6.1" (15.6 cm), Weight: Approx. 17.7 lbs. (8.0 kg)

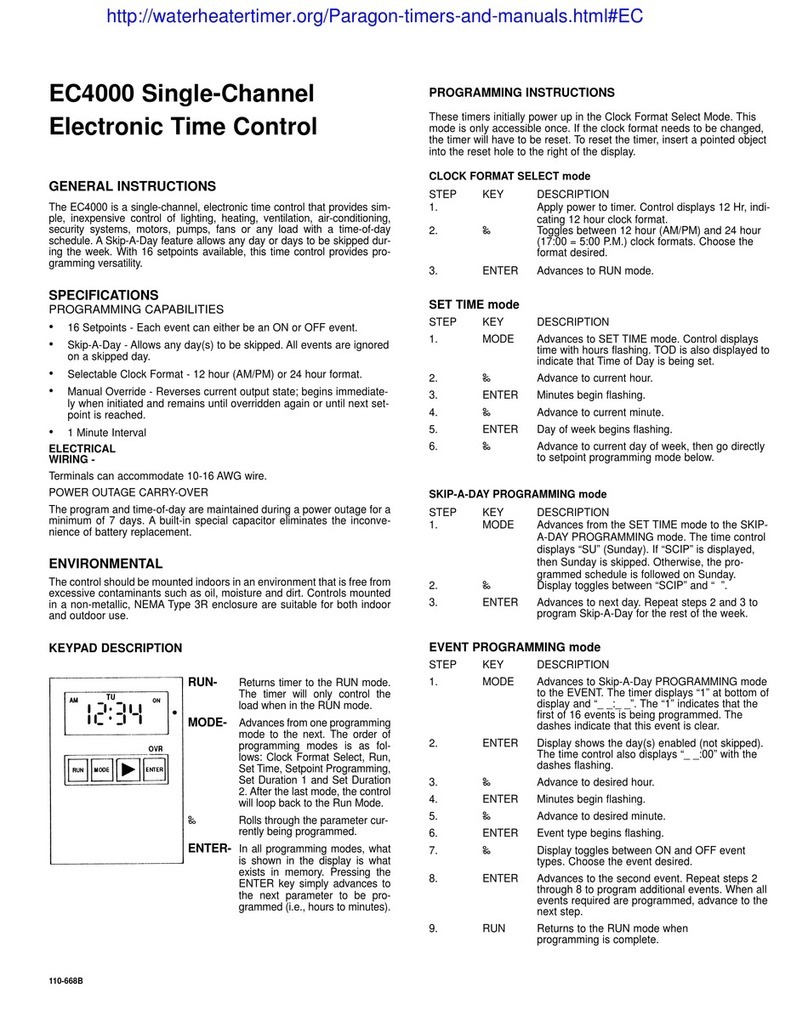

Introduction

The EL712 is a twelve-channel, electronic time control that provides simple, inexpensive con-

trol of lighting, HVAC, motors, pumps, bell-ringing or any electrical load with a time-of-day

schedule. The control may be utilized as a 24 hour, 7 day or full year (365 day) control.

The EL712 allows for the programming of 128 events. An event could be an ON, an OFF, one

of four user-defined durations or one of four user-defined duty cycle patterns. In addition, up

to 32 sensor events can be programmed to allow control based on temperature & light level.

Other parameters can be used; contact the factory for information.

The EL712 is a member of the EL series of time controls, that also includes the EL71, EL72, EL74,

and EL78 (1, 2, 4 and 8 channel, respectively). All are versatile, yet easy to program. A simple key-

pad combined with a large, user-friendly display takes the frustration out of programming.

Specifications

Programming Capabilities

•128 Events - An event can be an ON, an OFF, one of four user-defined durations or one of

four user-defined duty cycle patterns. Each event can be assigned to any channel. Each

event can be assigned to any day or any combination of days, including the three holiday

schedules.

•4 Durations - Each duration can be programmed from 1 second to 23 hours,59 minutes and

59 seconds.

•4 Duty Cycle Patterns - Each duty cycle pattern can be programmed with ON durations and

OFF durations from 1 second to 23 hours, 59 minutes and 59 seconds.

•8 User-Defined Inputs - Each input can be independently defined as one of two override

types, an enable input or as one of four sensor types.

•ON With Off Delay Override Input - Provides a retriggerable override input that is assignable

to any combination of outputs. The affected output(s) will be overridden ON with the closing

of the input and remain ON as long as the input is closed. When the input is opened, the

output(s) will remain ON for the length of the off delay. The off delay is programmable from 0

seconds to 23 hours, 59 minutes and 59 seconds. Closing the input during the off delay will

retrigger the override.

•Toggle Type Override Input - Provides a toggle type override input that is assignable to any

combination of outputs. Closing the input causes the affected output(s) to be toggled to the

opposite state and remain in that state until the occurrence of the next programmed event.

An optional timed-on from 1 second to 23 hours, 59 minutes and 59 seconds can be pro-

grammed. Upon completion of this timed-on, the affected output(s) will return to the pro-

grammed state unless toggled off.

•Enable Input - The enable input is assignable to any combination of outputs. The enable

input acts as a switch which opens and closes in series with the output(s). When open, the

load(s) will remain off. When closed, the output(s) follow the scheduled events.

•Sensor Input - The inputs can be configured as one of four sensor types:

F = degrees Fahrenheit (-40 to 215)

C = degrees Celsius (-40 to 102)

L = light level (0 to 100)

U = undefined (0 to 255)

•32 Sensor Events - A sensor event will control a channel based on programmable on/off

sensor levels. Each sensor event can be assigned to any day or combination of days,

including the three holiday schedules.

•Optional Daylight Savings Correction - Programmable as a day of the month (i.e. 1st Sunday

in April / last Sunday in October)

•Leap Year Correction to the Year 2100

•10 Single Day Holidays - (e.g. July 4th)

•10 Day of Month Type Holidays - (e.g. last Monday in May)

•10 Holiday Durations - Programmable from 1 to 366 days (e.g. June 9th to August 27th)

•6 Specific Holidays - Each holiday can be optionally selected

Good Friday Easter Sunday Easter Monday

Boxing Day Victoria Day Thanksgiving Thursday and Friday

32