Bulletin 4391-B400S EXACTOL®400 Series Tube Benders

5Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

www.parker.com/tfd

Medium to Heavy Wall Tube Bending

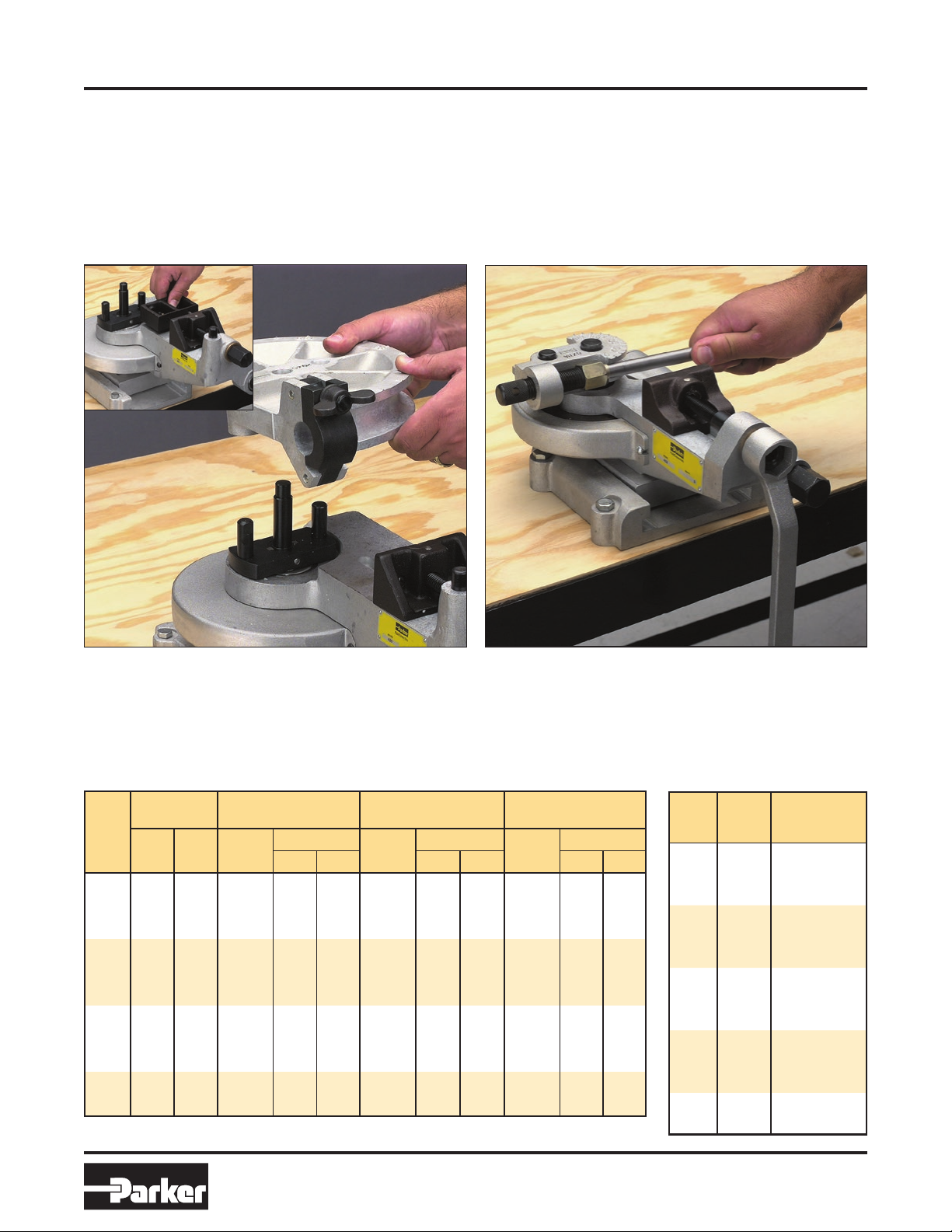

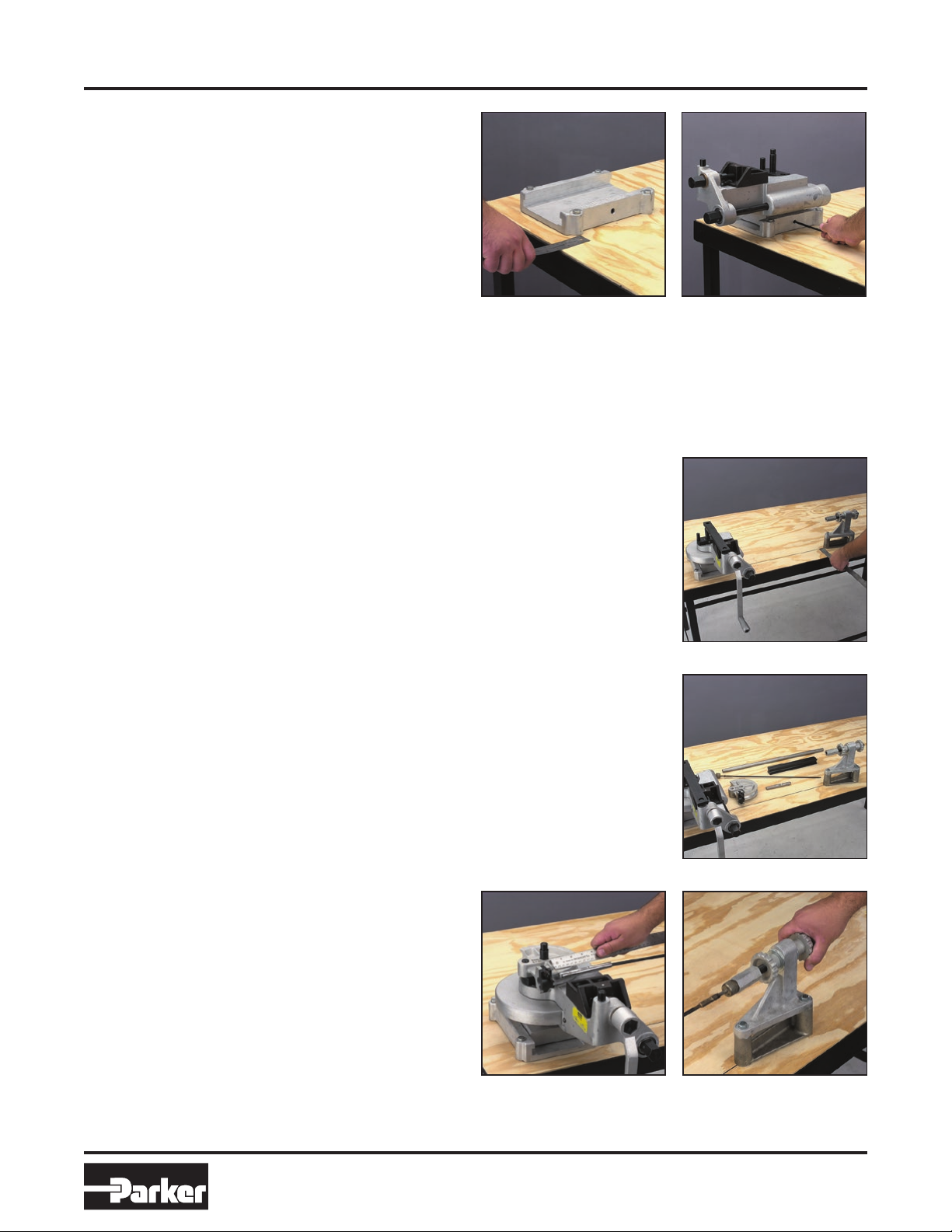

Step 5: Select Slide Block Groove

Select the proper groove of the slide block for the outside diameter

of the tube (sizes are marked on the end of the slide block) and

position the slide block accordingly, against the slide block vise face

with the end of the block adjacent to the tube clamp of the radius

block. Lubricate the slide block to facilitate sliding. Then, advance

the slide block by means of the telescopic adjustment screw, to rest

snugly against the tube, but not with so much pressure as to pre-

vent the block from sliding easily along the slide block vise face.

Step 6: Using the Tie Bar (if required)

When it becomes difficult to hold distortion of the tube within 5%

because of deflection of the bender, place the tie bar over the

center post and the dowel pin. Always use the tie bar with heavy

wall tubing — sizes 7/8" or above.

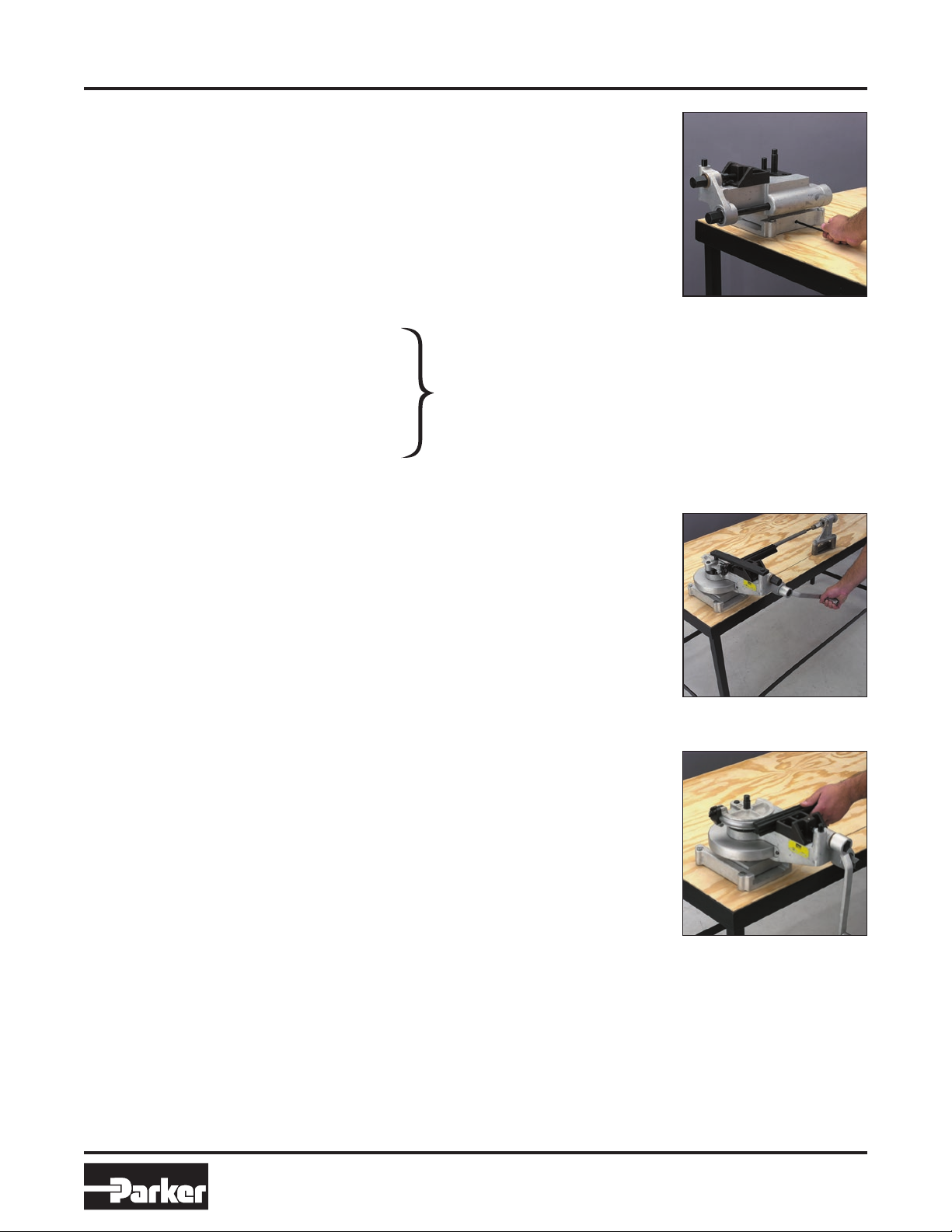

Step 7: Bend the Tube

Tube bending is accomplished with ease by means of the crank

handle operating the mechanism through 60:1 ratio worm gear.

As the bend is being made, the slide block travels with the tube

and bears lightly against the radius block to form a true round die

enclosing the tube, providing a smooth, full cross-section bend. The

angle of the bend is indicated by the marks on the radius block. At

the completion of bend the desired degree mark will be in line with

the left side of the bender.

Step 8: After Bending the Tube

First, remove the tie bar, if in use. Next,

retract the slide block vise and remove the

slide block.

Step 9: Completed Bent Tube

Loosen the wing nut on the clamp, open, pull

the tube out from the radius block and lift up.

Your tubing is smoothly bent, without flatten-

ing or cracking.

To reset the tube bender, turn the worm

wheel shaft counterclockwise to disengage.

Turn the radius block back until the 0° mark

is at its original starting point. The bender is

then ready for inserting the next tube. Then

turn the worm wheel shaft in clockwise direc-

tion to re-engage the gear for the start of the

next bend.

Bends from 90° to 180° — The 400 Series Tube Benders bend tubing up to 180° with ease. The procedure for

bends over 90° is the same as for bends to 90°. See Step 4.