SPL002 ---030 (60Hz) 2

English

2.3 Inspection

a) All units are assembled, wired, filled with coolant and oil,and

tested under standard operating conditions in the factory;

b) on receiving the machine check its condition: immediately

notify the transport company in case of any damage;

c) unpack the unit as close as possible to the place of installa-

tion.

2.4 Storage

If several units have to stacked, follow the notes given on the

packing. Keep the unit packed in a clean place protected from

damp and bad weather.

3 Installation

3.1 Procedures

Install the dryer inside, in a clean area protected from direct at-

mospheric agents (including sunlight).

YComply with the instructions given in par. 8.2 and 8.3.

All dryers must be fitted with adequate pre---filtration near the

dryer air inlet. Seller is excluded any obbligation of compensation

or refund for any direct or indirect damage caused by its absence..

YPre---filter element (for 3 micron filtration or better) must

be replaced at least once a year, or sooner as per manufacturer

recommendations.

YDo not invert the compressed air inlet and outlet connec-

tions and observe the maximum tightening torque (N x m) as spe-

cified in par. 8.3.

3.2 Operating space

YLeave a space of 60 inches (1.5 m) around the unit.

3.3 Tips

To prevent damage to the internal parts of the dryer and air com-

pressor, avoid installations where the surrounding air contains

solid and/or gaseous pollutants (e.g. sulphur, ammonia, chlorine

and installations in marine environments).

The ducting of extracted air is not recommended for versions with

axial fans.

3.4 Electrical connection

Use approved cable in conformity with the local laws and regula-

tions (for minimum cable section, see par. 8.3).

Install a differential thermal magnetic circuit breaker with

contact opening distance ²0.12 inches (3 mm) ahead of the sys-

tem (IDn = 0.3A) (see the relevant current local regulations).

The nominal current In of the magnetic circuit breaker must be

equal to the FLA with an intervention curve type D.

3.5 Condensate drain connection

The dryer is supplied either with a float drain, a timed drain or an

electronic level sensing drain.

If a timed or electronic unloader is installed, use terminals CN

(R1---S1) (see par. 8.8).

For timed and electronic drains: refer to separate manual sup-

plied with the dryer for specific details concerning the condensate

drain.

YMake the connection to the draining system, avoiding con-

nection in a closed circuit shared by other pressurized discharge

lines. Check the correct flow of condensate discharges. Dispose

of all the condensate in conformity with current local environ-

mental regulations.

4 Commissioning

4.1 Preliminary checks

Before commissioning the dryer, make sure:

a) installationwas carriedout accordingthat givenin the section

3;

b) the air inlet valves are closed and that there is no air flow

through the dryer;

c) the power supply is correct;

4.2 Starting

a) Start the dryer before the air compressor by means of the

main power switch 14 ; the power lamp will illuminate

(green);

b) after at least 5 minutes slowly open the air inlet valve and

subsequently open the air outlet valve: the dryer is now

performing its air drying function.

4.3 Operation

a) Leave the dryer on during the entire period the air compres-

sor is working;

b) the dryer operates in automatic mode, therefore field settings

are not required;

c) in the event of unforeseen excess air flows, by---pass to avoid

overloading the dryer;

4.4 Stop

a) Stop the dryer 2 minutes after the air compressor stops or in

any case after interruption of the air flow;

b) do not allow compressed air to flow through the dryer when

the latter is not running;

c) switch off at the main power switch 14 . The power light goes

out and the compressor stops.

d) SPL002: after switching off the unit, wait at least five minutes

allowing internal pressure to equalize before switching on

again the dryer; pay attention to possible power failure.

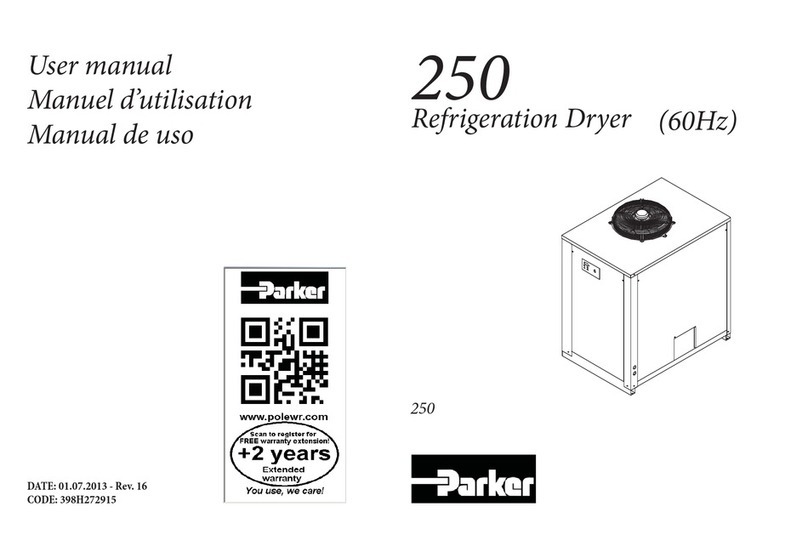

5 Control

Dewpoint indicator

Main power switch

The dewpoint indicator can show one of three conditions:

blue: dewpoint too low

green: dewpoint ideal

red: dewpoint too high

14

11

14 11