Online Manuals This manual (in Acrobat PDF format) is available from our web site: http://www.compumotor.com

ABOUT THIS GUIDE

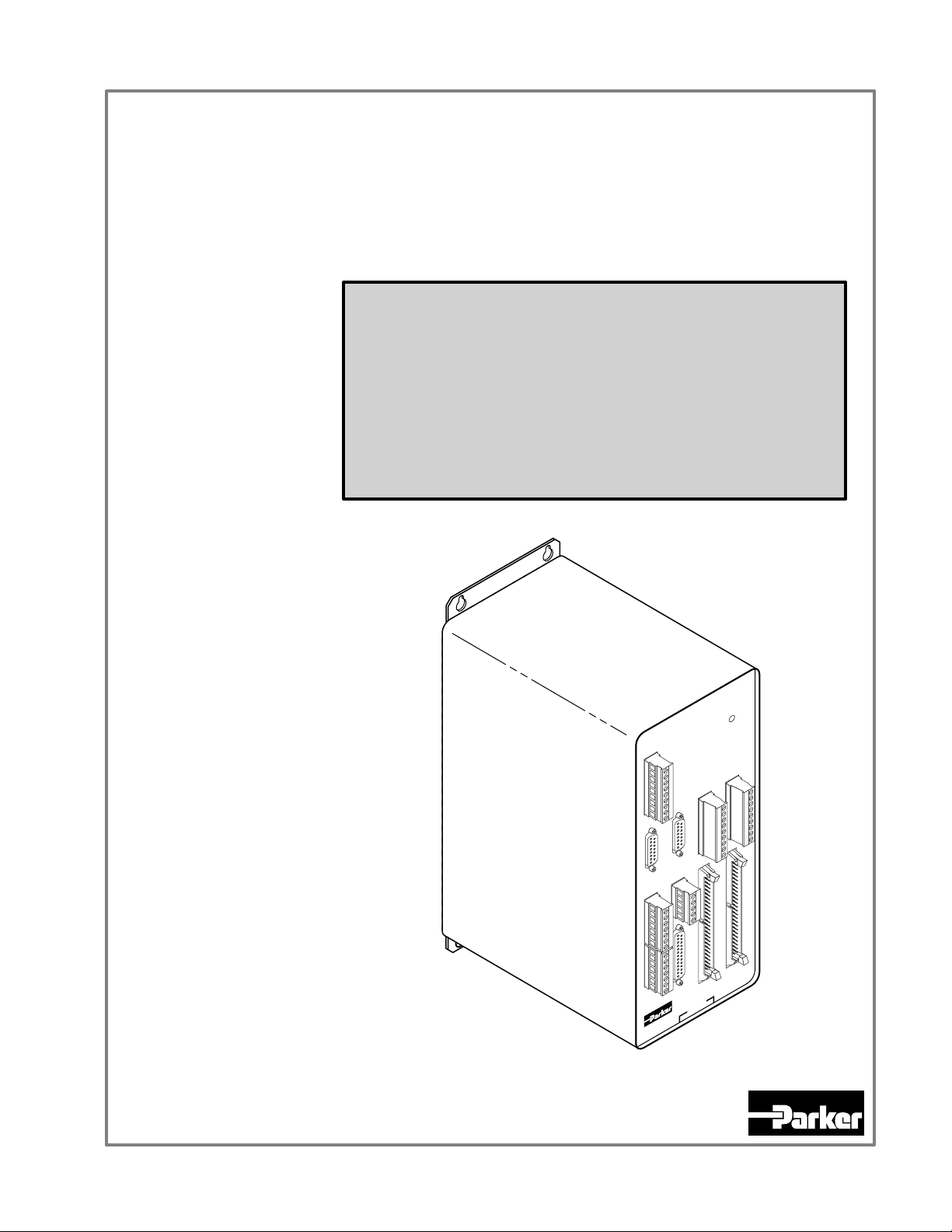

Chapter 1. Installation

What You Should Have (ship kit)...........................................................2

Before You Begin.....................................................................................2

Recommended Installation Process.............................................2

Electrical Noise Guidelines...........................................................2

General Specifications............................................................................3

Pre-installation Adjustments...................................................................4

Mounting the 6200....................................................................................5

Electrical Connections............................................................................6

Grounding System..........................................................................6

Serial Communication (RS-232C)...............................................7

Pulse Cut-off (P-CUT) Input — Emergency Stop Switch...........7

Motor Drivers.................................................................................8

End-of-Travel and Home Limit Inputs.........................................10

Encoder.........................................................................................11

Joystick & Analog Inputs .............................................................12

Trigger Inputs................................................................................13

General-Purpose Programmable Inputs & Outputs...................14

RP240 Remote Operator Panel...................................................18

Input Power...................................................................................18

Lengthening I/O Cables................................................................19

Testing the Installation...........................................................................20

What’s Next?.........................................................................................22

Program Your Motion Control Functions....................................22

Chapter 2. Troubleshooting

Troubleshooting Basics.........................................................................24

Reducing Electrical Noise...........................................................24

Diagnostic (“STATUS”) LED......................................................24

Test Options..................................................................................24

Technical Support.........................................................................24

Common Problems & Solutions...........................................................25

Troubleshooting Serial Communication Problems.............................26

Product Return Procedure....................................................................27

Appendix A (LVD Installation Instructions)......................29

Appendix B (EMC Installation Guidelines)........................31

Index..................................................................................................35

Quick Reference...............................................(see back cover)

Purpose of This Guide

This document is designed to help you install and troubleshoot your 6200 hardware system.

Programming related issues are covered in the 6000 Series Programmer’s Guide and the 6000

Series Software Reference.

What You Should Know

To install and troubleshoot the 6200, you should have a fundamental understanding of:

• Electronics concepts, such as voltage, current, switches.

• Mechanical motion control concepts, such as inertia, torque, velocity, distance, force.

• Serial communication and terminal emulator experience: RS-232C

Related Publications •6000 Series Software Reference, Parker Hannifin Corporation, Compumotor Division;

part number 88-012966-01

•6000 Series Programmer’s Guide, Parker Hannifin Corporation, Compumotor Division;

part number 88-014540-01

• Current Parker Compumotor Motion Control Catalog

• Schram, Peter (editor). The National Electric Code Handbook (Third Edition). Quincy,

MA: National Fire Protection Association

LVD & EMC Compliance

The 6200 is in compliance with the Low Voltage Directive (72/23/EEC) and the CE Marking

Directive (93/68/EEC) of the European Community.

When installed according to the procedures in the main body of this installation guide, the 6200

may not necessarily comply with the Low Voltage Directive (LVD). To install the 6200 so

that it is LVD compliant, refer to supplemental installation instructions provided in Appendix

A. If you do not follow these instructions, the protection of the 6200 may be impaired.

The 6200 is sold as a complex component to professional assemblers. As a component, it is

not required to be compliant with Electromagnetic Compatibility Directive 89/336/EEC.

However, Appendix B provides guidelines on how to install the 6200 in a manner most likely

to minimize the 6200’s emissions and to maximize the 6200’s immunity to externally

generated electromagnetic interference.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com