http://www.parker.com/ppf

Page 7

IV. BACKGROUND

In 1977, Dr. R.E. McCaman and associates

provided a complete description (1) of a pressure

ejection system that utilized a high speed valve.

This valve continues to be the heart of the pressure

system offering very precise control of ejection

volumes (in the picoliter range) and ejection times

(in the millisecond range).

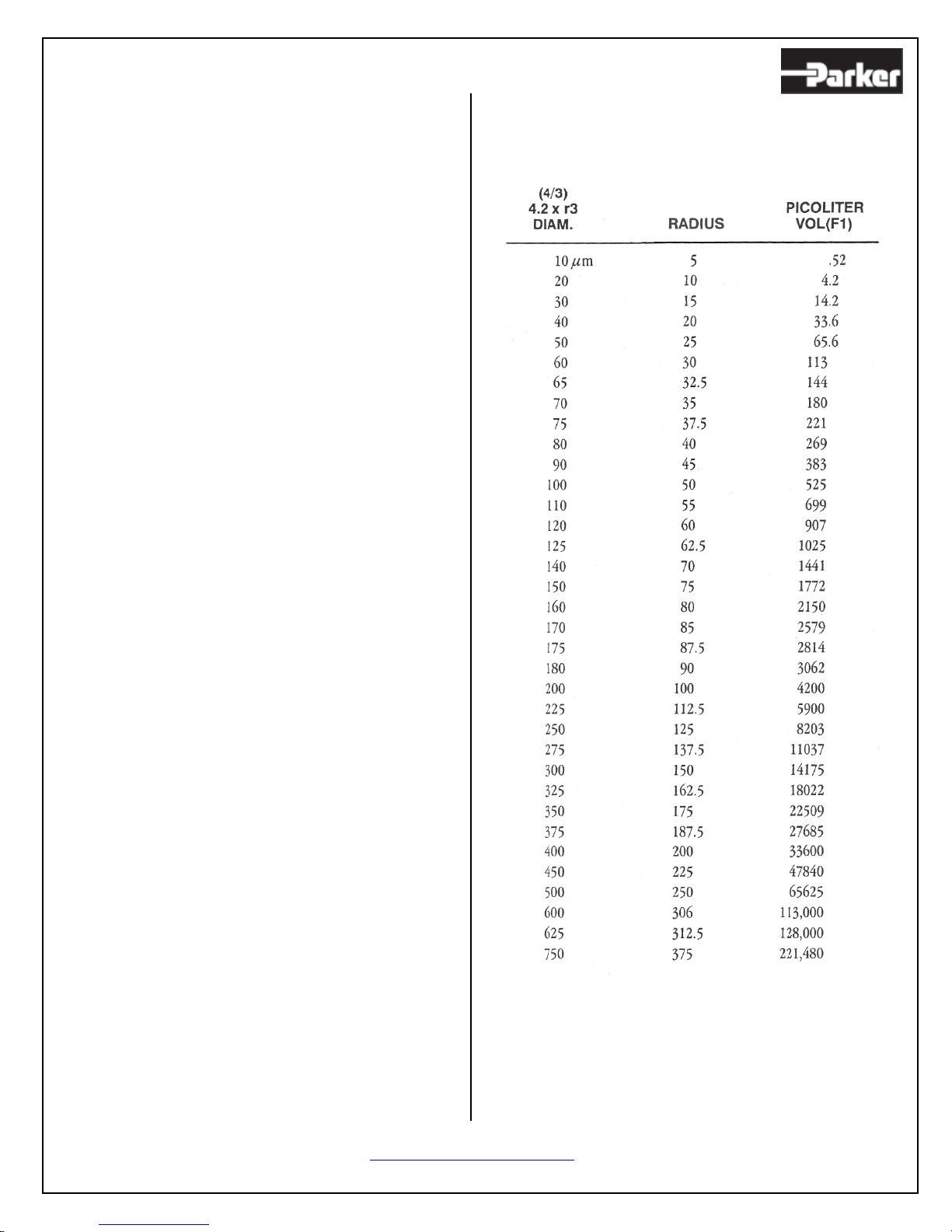

Furthermore, these investigators described a series

of holders that permitted ejection through

micropipettes with sufficiently small tips that could

be used for simultaneous intracellular recordings

during ejections.

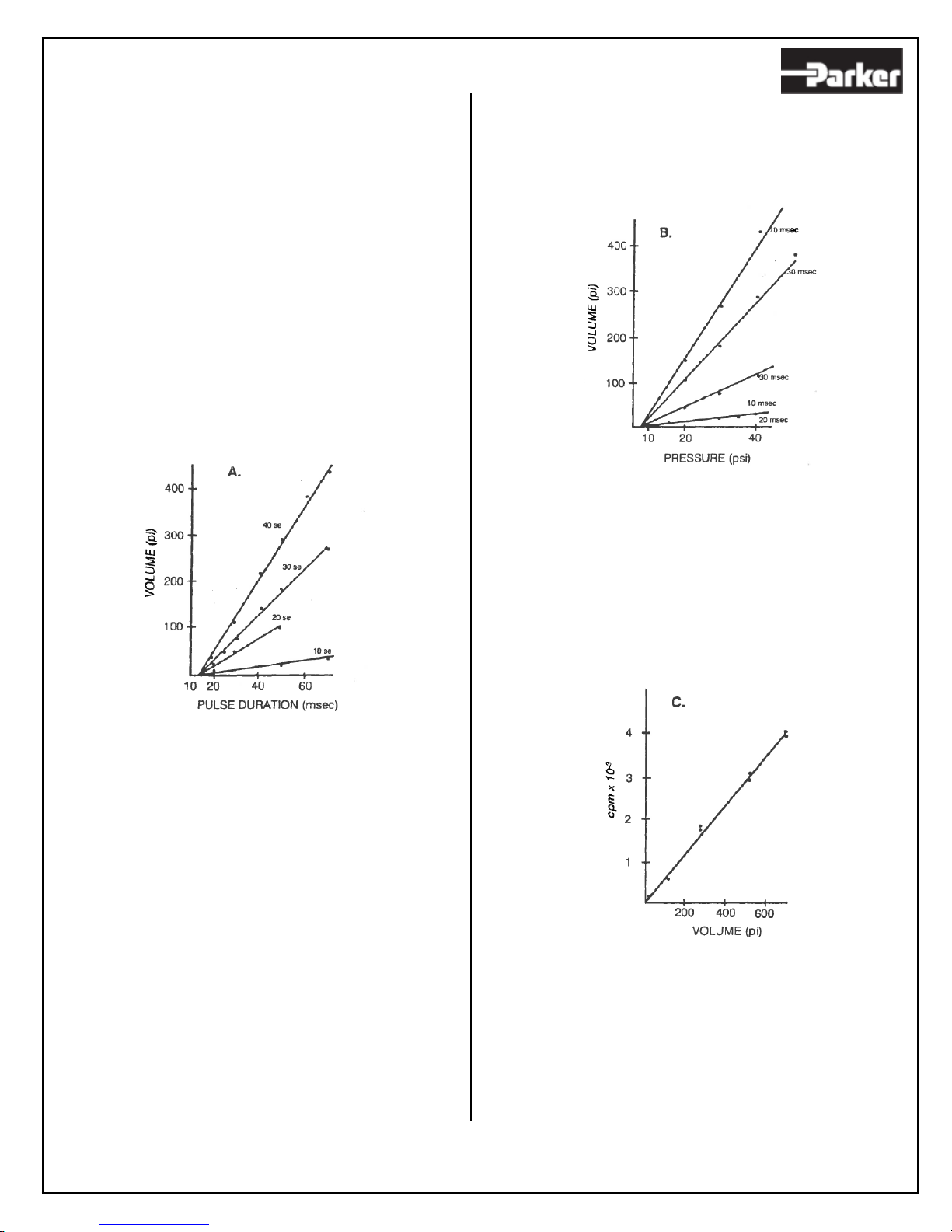

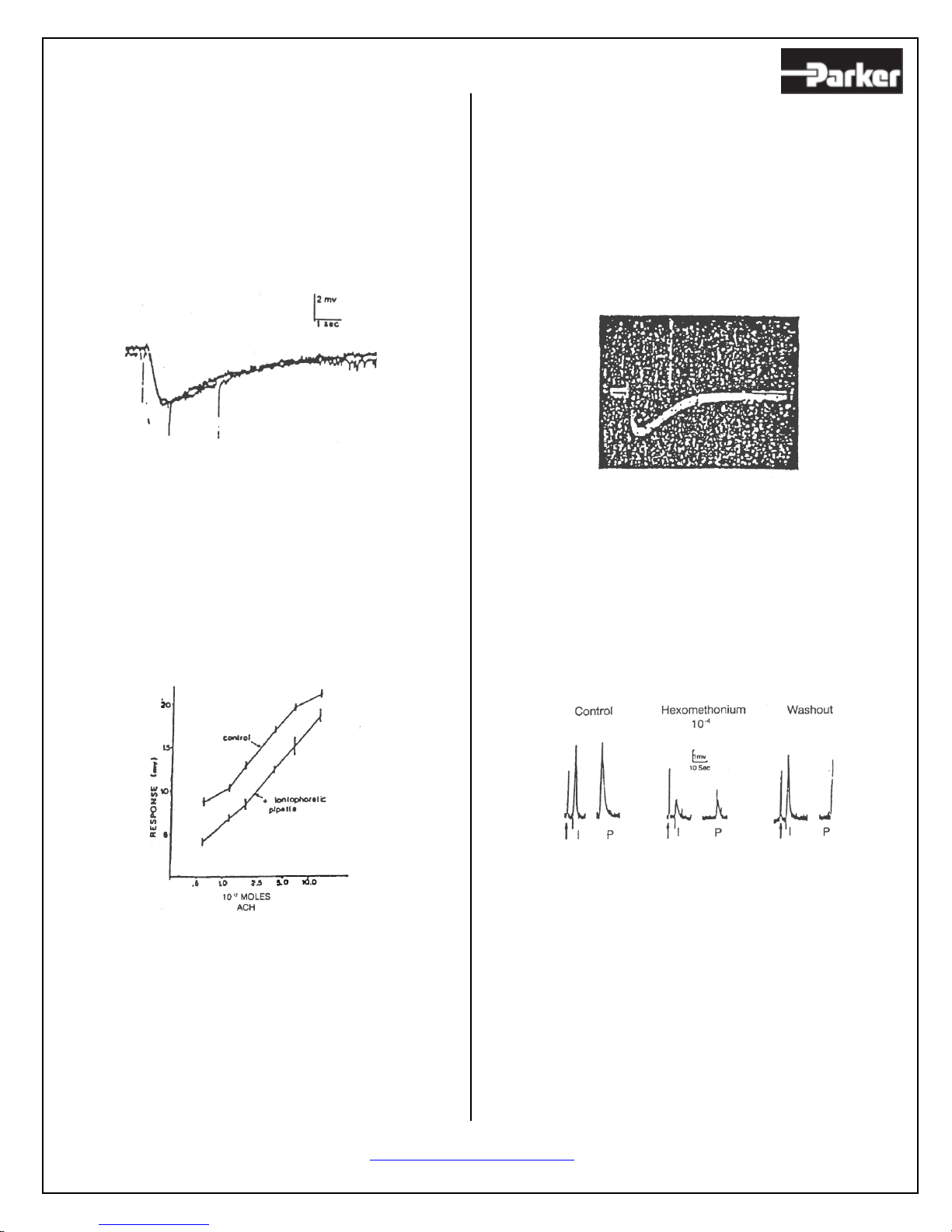

These systems have been used for intracellular as

well as extracellular ejections. In listing advantages

of the pressure system, these investigators

emphasize that the linear relationship between

ejection volume and either duration of the pulse or

of the applied pressure permits a rapid, convenient

and reliable calibration of each pipette (1, 3), unlike

that for electrophoretic techniques (7-9).

Pressure ejection seems an ideal approach to

delivering uncharged substances such as peptides

(4, 6), steroids (4), and enzymes (2,5). The

solutions used for pressure ejections are usually

several orders of magnitude more dilute than those

used for electrophoretic ejection (1, 3), thus

avoiding receptor desensitization commonly

experienced with iontophoresis. The fact that the

ejection efficiency of the pneumatic systems is not

influenced by solute concentration nor by net

charge, makes them ideal for intracellular injections

of radiolabeled or tracer substances (13-15).

Thus, pressure systems have been used for

intracellular injection of radiolabeled precursors or

neurotransmitters (10, 11) and [H3] –sugars as

precursors of glycoproteins (12) in order to study

neuron-specific transmitter biosynthesis, axonal

transport and cellular topography. The reproducible

and quantifiable ejections obtained with pressure

systems make them ideal for neuropharmacological

studies of agonist and drug interactions with

membrane receptors (1, 3, 4).

As you find additional uses for your Picospritzer,

please send us a reprint for addition to our reference

section so that others may benefit from your

experience.

N.B.; H3=radioactivity (tritium) label substance.

REFERENCES

References describing the use and unique advantage

of pressure systems in several types of

experimentation in the field of neurobiology, cell

biology, and biophysics are:

1. McCaman, R.E., Mc Kenna, D.G. and Ono, J.K.

“A pressure system for intracellular and extracellular

ejections of picoliter volumes.” Brian Research

136:141 (1977).

2. Sakaki, M., Sakai, H. and Woody, C.D.

“Intracellular staining of cortical neurons by pressure

micro-injection of horseradish peroxidase and

recovery by core biopsy.” Exp. Neurol. 58:138

(1978)

3. Sakai, M., Swartz, B.E. and Woody, C.D.

“Controlled micro release of pharmacological agents:

measurements of volume ejected in vitro through fine

tipped glass microelectrodes by pressure.”

Neuropharmacol. 18:209 (1979)

4. Dufy, B., Vincent J-D. Fluery, H., Pasquier, P.,

Gourdji, D., and Tixler- Vidal, A. “Membrane effects

of thyrotropin-releasing hormone and estrogen shown

by intracellular recording from pituitary cells.”

Science. 204.509 (1979)

5. Tauc, L., Hoffman, A., Tsuji, S., Hinzen, D. and

Faille, L. “Transmission abolished in a cholinergic

synapse after injection of acetylcholinesterase into

the presynaptic neuron.” Nature, 250, 496 (1974)

6. Chang, J.J., Gelperin, A., and Johnson, F.H.

“Intracellulary injected aequorin detects

transmembrane calcium flux during action potentials

in an identified neuron from the terrestrial slug.”

Brain Research 77:431 (1974)