Contents

Contents Page

Cont.4

ETHERNET COMMUNICATIONS INTERFACE 1

Introduction ..................................................................................................... 1

Product Features ........................................................................................................ 1

Product Codes ........................................................................................................... 1

Installation....................................................................................................... 2

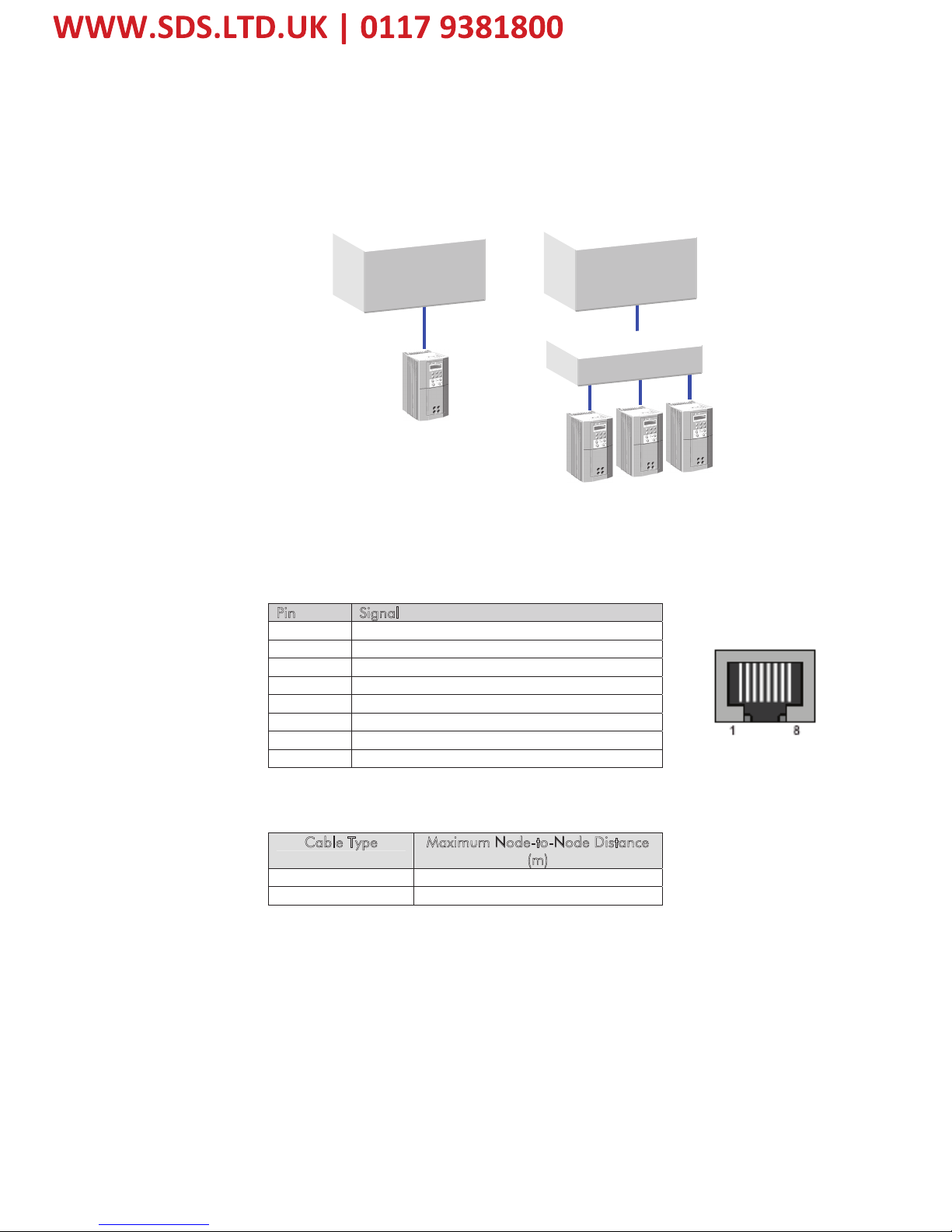

Wiring the System ...................................................................................................... 5

LED Indications ................................................................................................ 6

Network Status LED (NS)............................................................................................. 6

•Modbus/TCP ........................................................................................... 6

•Ethernet/IP .............................................................................................. 6

Module Status LED (MS).............................................................................................. 7

•Modbus/TCP ........................................................................................... 7

•Ethernet/IP .............................................................................................. 7

LINK/Activity LED........................................................................................................ 7

Drive Diagnostics............................................................................................. 8

•The Ethernet MMI View............................................................................. 8

•Parameter Descriptions ............................................................................ 8

Configuring the Ethernet System..................................................................... 9

Step 1: Configuring the Ethernet TechCard using DSE 890........................................... 9

•Step 1.1: Inserting an Ethernet Function Block ........................................... 9

•Step 1.2: Attaching Fieldbus Connectors ................................................. 10

•Step 1.3 : Configuring the Fieldbus Connectors....................................... 11

•DSE Data Types ..................................................................................... 13

•Ethernet Data Types ............................................................................... 13

•Conversion of DSE Type < > Ethernet Type ............................................ 13

Step 2: Configuring the PLC/SCADA Supervisor......................................................... 14

•Modicon Momentum.............................................................................. 14

•Allen Bradley ControlLogix ..................................................................... 16

•TS8000 Operator Station using DSI8000 ................................................ 18

Configuring DSE to Connect over Ethernet .................................................... 22

Appendix A: Ethernet Error Codes................................................................. 23

Appendix B : DSE/Ethernet Conversion Rules ............................................... 29

•LOGIC Type Connector ......................................................................... 29

•INTEGER Type Connector....................................................................... 29

•VALUE Type Connector .......................................................................... 30