I/O Data Exchange

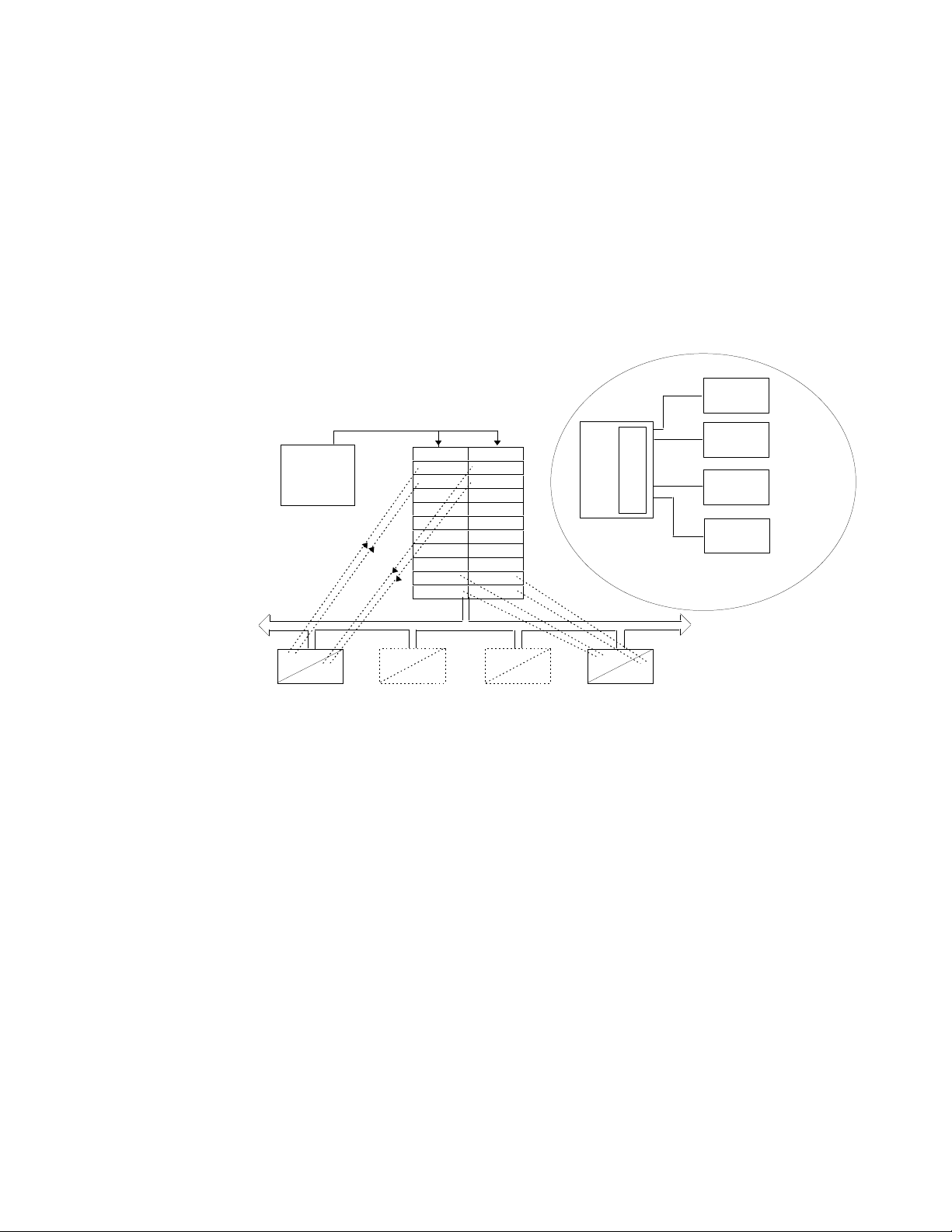

The process of reading the inputs and writing to the outputs is known as an

I/O data exchange. Typically, the parameters from each slave device will be

mapped to an area of PLC input and output registers or a single function

block so that the controlling ladder logic or program interfaces with the

device as if it were an internally fitted module. It is NOT necessary,

therefore, for the programmer to know anything about the physical network.

The process of network configuration is usually performed using a PC based

program, which allows the devices on the network to be defined and device

parameters to be mapped into the PLC registers or function blocks.

The cyclical scan occurs in the following order:

1. Values from each slave device, ‘Input Data’, are first scanned over the

network into a pre-defined set of input registers in the master controller.

The values might be a set of digital input readings for a digital input unit,

or the measured temperature and alarm status from a PID controller.

2. The master then runs its control program, (such as a ladder logic

program) using the input data read from the slave devices.

3. The master writes output values (output data) into a pre-defined set of

output registers. For example, one of the digital inputs read in the input

data might be used to select one of a set of setpoints to be sent to the

PID controller.

4. These outputs are then written to each slave device, and the scan-

process-write cycle repeats.

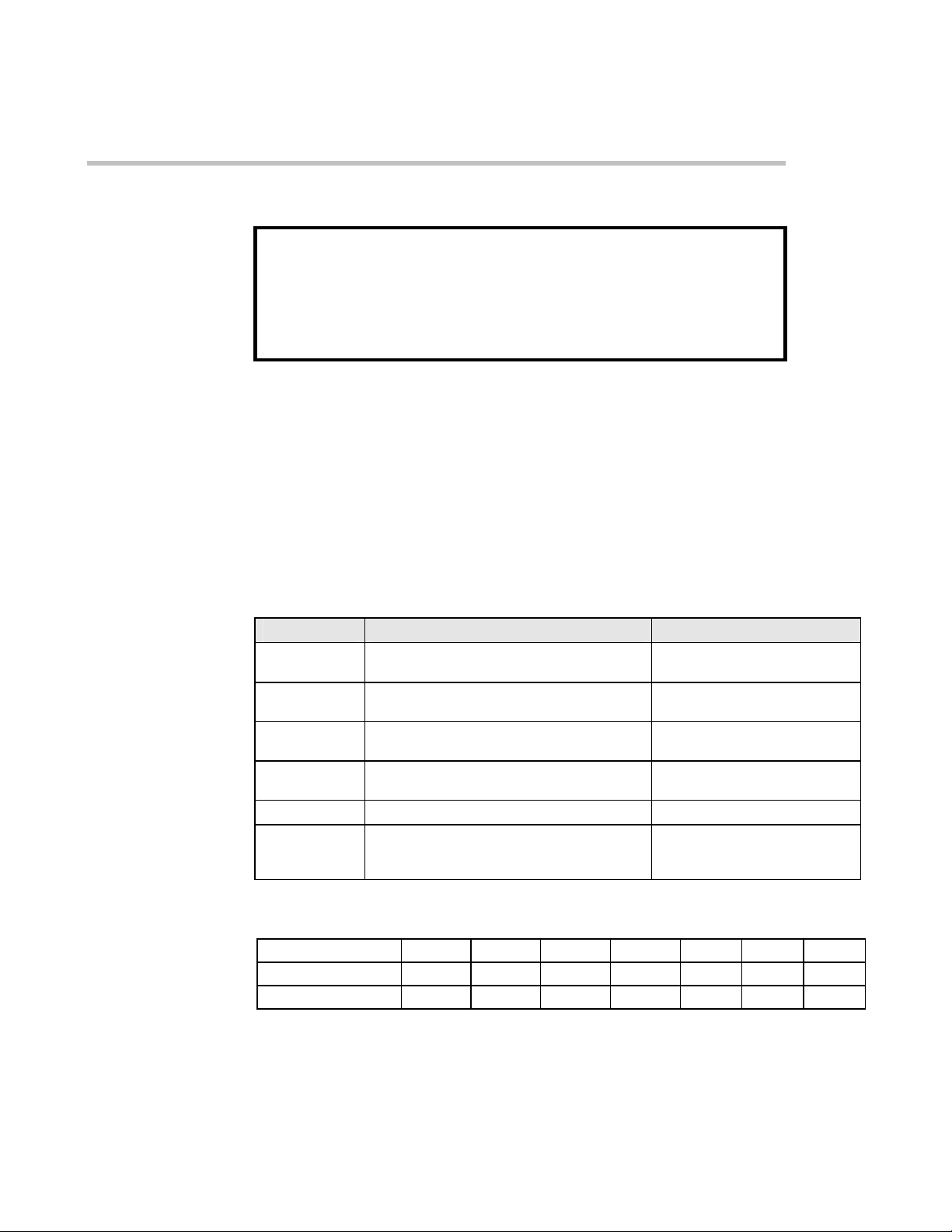

Typically no more than 16 bits of input data and 16 bits of output data are

exchanged for each device during the data exchange. The Profibus

LinkCard implementation of the PROFIBUS-DP standard provides the

possibility of transferring 112 words in each direction.

The input and output data lengths for a given device is variable and it is

possible to have devices with only input data, only output data, or both.

The input and output data mixture used by a given slave device is defined by

the GSD file. For simple devices such as digital or analog I/O blocks, it is

fixed. However, since more complex devices often have a much wider

choice of possible values to send, it is usually possible to edit the GSD file to

change the mapping of device parameters into Profibus inputs or outputs.

This is the case with the Profibus LinkCard, which also allows access to

parameter data not in the GSD Input/Output data file.

The GSD file is imported into the PROFIBUS Master Network Configuration

software before the network is created.

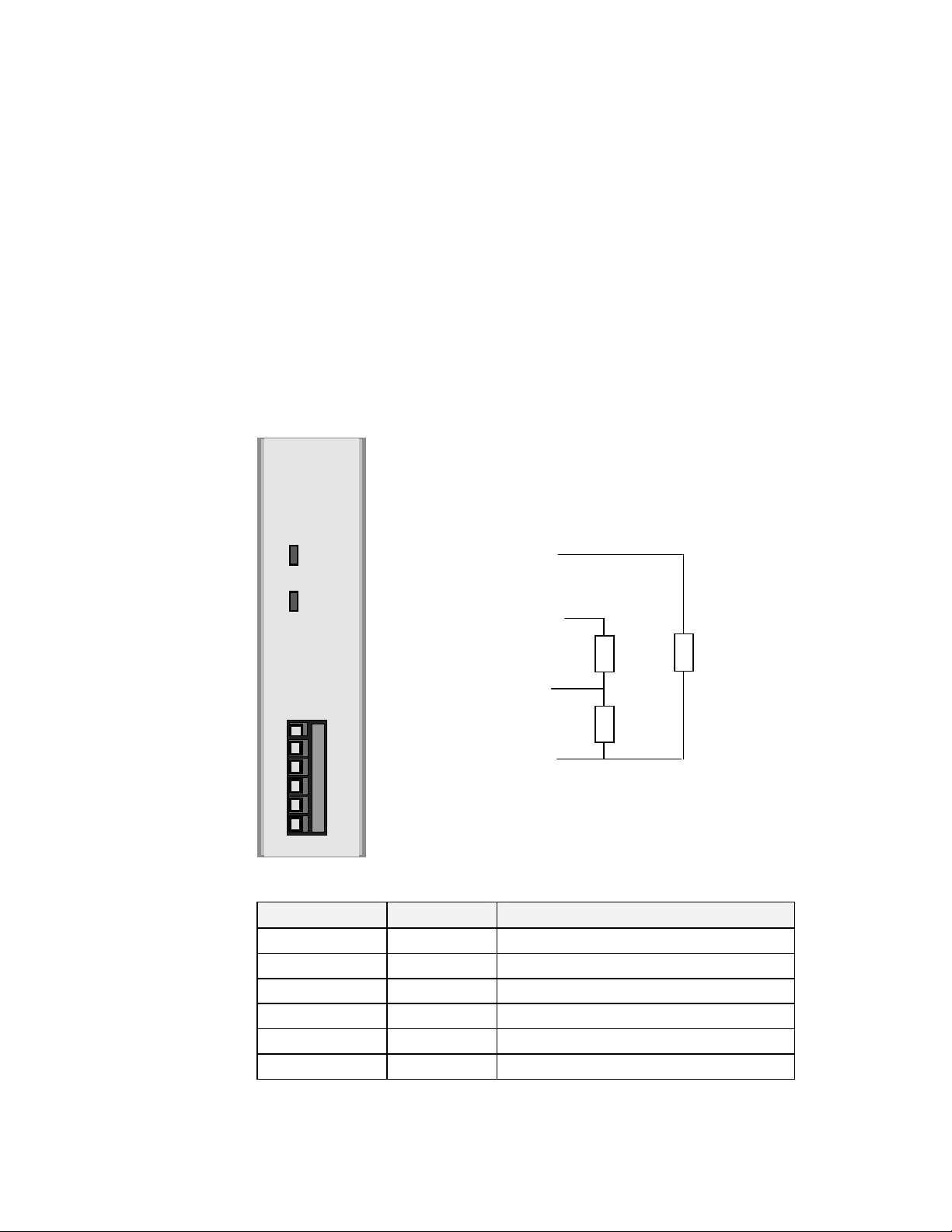

Note: PROFIBUS Input Data =Values sent from a slave device to a

master controller or PLC.

PROFIBUS Output Data =Values sent from a master controller or PLC

to a slave device.

DSD viewpoint is looking toward the master controller or PLC.

Profibus Write block is data transfer to the master controller or PLC.

Profibus Read block is data transfer from the master controller or PLC.