Table of Contents

i

TABLE OF CONTENTS

HowToUseThisUserGuide ....................................................................................................................i

Assumptions.................................................................................................................................i

User Guide Contents ......................................................................................................................i

Installation Process Overview................................................................................................................ii

Installation Procedures...................................................................................................................ii

Related Publications.............................................................................................................................ii

INTRODUCTION...............................................................................................................................1

ProductDescription..............................................................................................................................1

RP240 Features...................................................................................................................................1

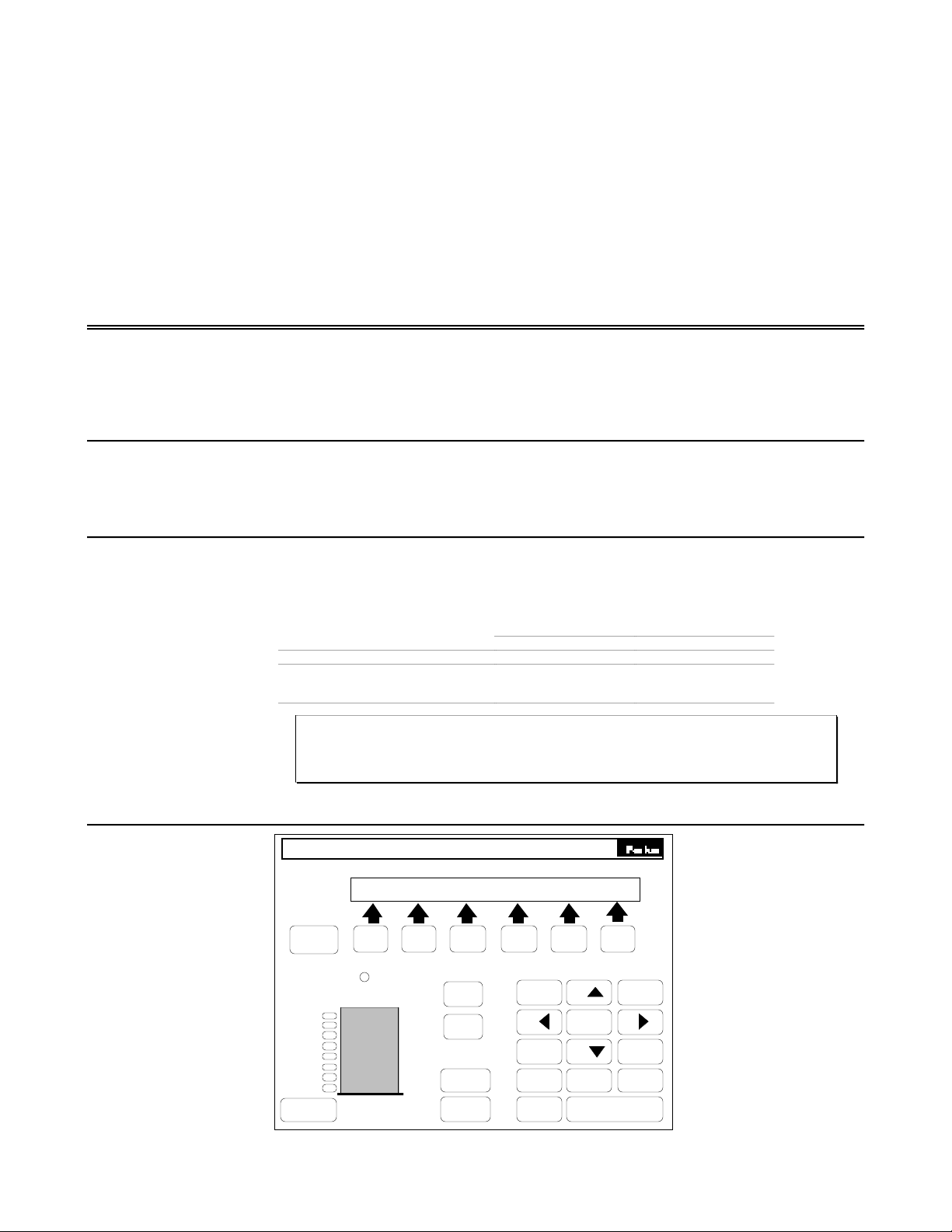

GETTING STARTED.........................................................................................................................3

WhatYouShouldHave...........................................................................................................................3

Basic System Configuration...................................................................................................................3

Wiring Connections ........................................................................................................................4

INSTALLATION................................................................................................................................5

Environmental Considerations................................................................................................................5

Electrical Noise .............................................................................................................................5

Airborne Contaminants....................................................................................................................5

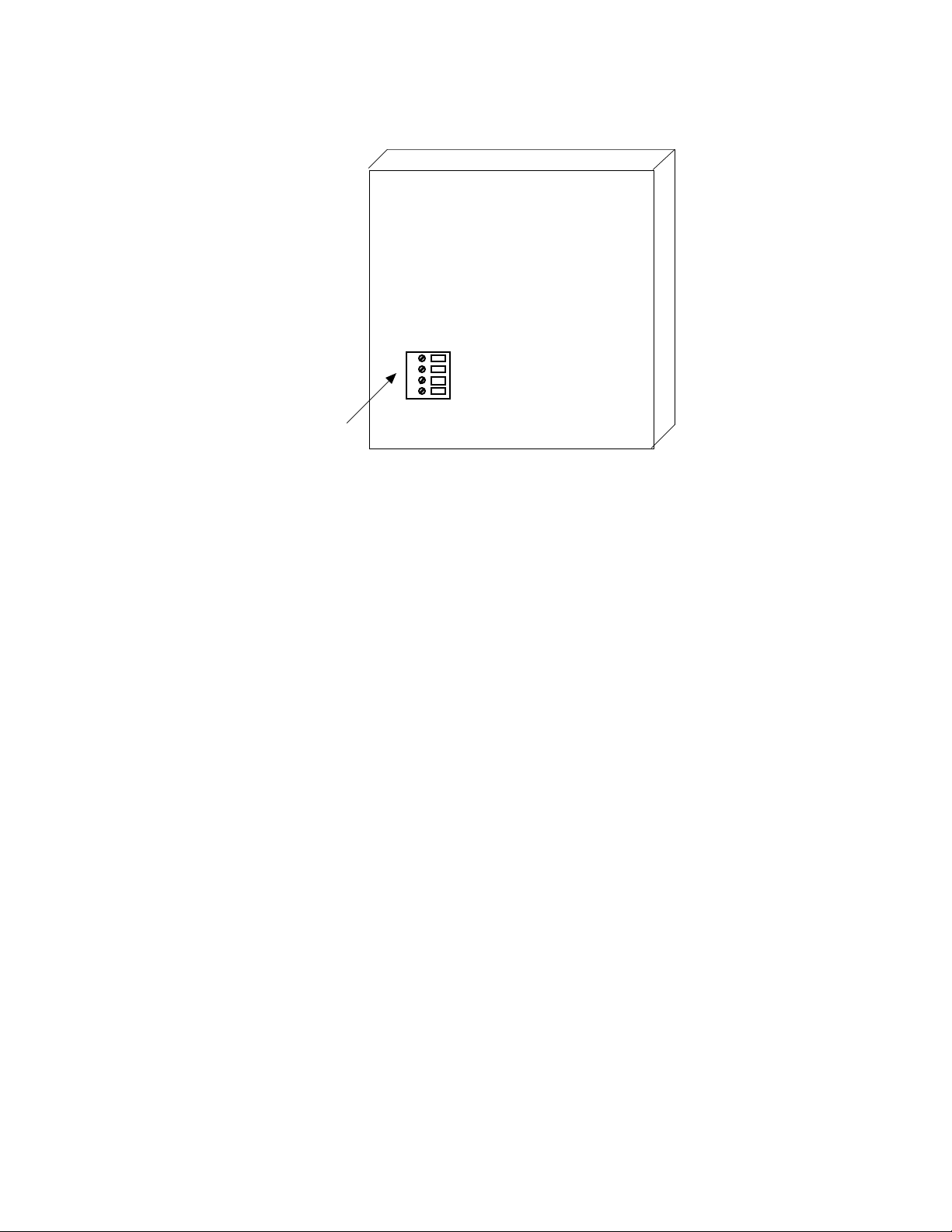

System Mounting.................................................................................................................................6

RP240 Door Mount .........................................................................................................................6

RP240 Dimensions.........................................................................................................................7

RP240-NEMA4 Door Mount ..............................................................................................................7

RP240Connections........................................................................................................................8

RP240toSXWiringDiagram..............................................................................................................9

RP240 to ZX Wiring Diagram.............................................................................................................9

RP240 to Model 500 Wiring Diagram...................................................................................................10

RP240 Connector Pin Out................................................................................................................10

Installation Verification.........................................................................................................................10

6000 Series ..................................................................................................................................10

Using the RP240 With An Extended X Language Product .......................................................................11

EXTENDED X COMMAND SUMMARY AND APPLICATION DESIGN...........................................13

Extended X Language Command Summary ...............................................................................................13

Description of Extended X Language Command Format ...............................................................................14

Extended X Language Command Listing...................................................................................................15

Discussion of Extended X Language Commands........................................................................................20

Prompting an Operator or Displaying Information..................................................................................20

Extended X Language Command Programming Example........................................................................21

Processing Information...................................................................................................................23

Enabling STOP and PAUSE Keys......................................................................................................23

Sample Program ............................................................................................................................24

Editing Sequences.........................................................................................................................29

Daisy Chaining ..............................................................................................................................30

6000 SERIES COMMAND SUMMARY AND APPLICATION DESIGN............................................33

6000 Series Command Summary.............................................................................................................33

Description 6000 Series Command Format ................................................................................................34

RP240 X Language Command Listing.......................................................................................................35

Prompting an Operator or Displaying Information..................................................................................38

6000 Series Command Programming Example......................................................................................39

Processing Information...................................................................................................................41

Enabling Jog Mode.........................................................................................................................41

ChangingthePassword ...................................................................................................................41

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com