GB

2Parker Hannifin icountPDR

Contents

Overview ...................................................................................................3

Conditions for safe use.............................................................................3

Laser Information.....................................................................................3

EC Declaration of Conformity...................................................................4

Product identification label ......................................................................5

Introduction............................................................................. 6

Principles of operation .............................................................................6

Benefits.....................................................................................................7

Technical specification .............................................................................8

Software default settings .........................................................................9

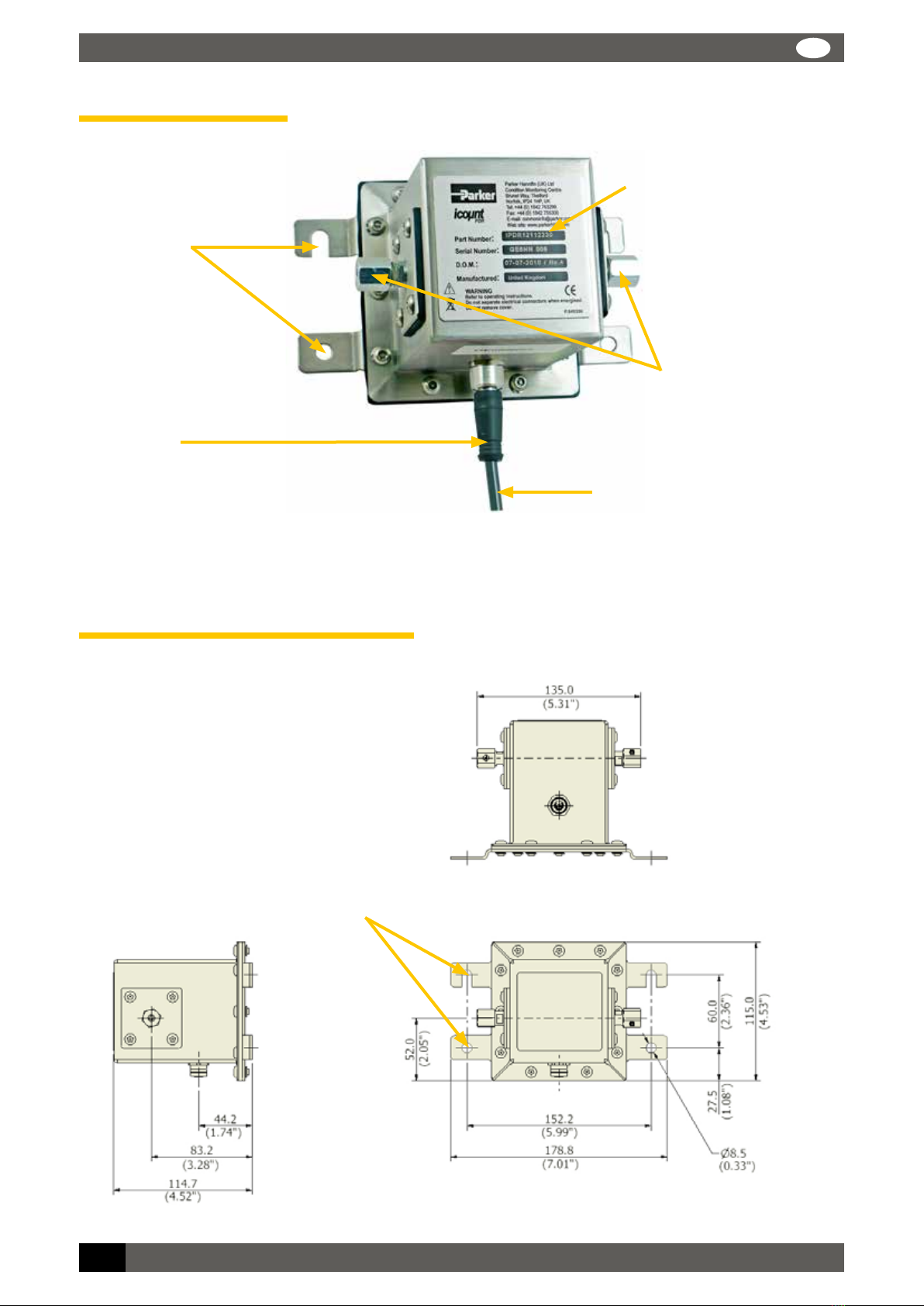

Product features.....................................................................................10

Dimensions for installation ....................................................................10

Connections........................................................................... 11

Hydraulic connection..............................................................................11

Flow control............................................................................................12

System 20 sensor connection ................................................................14

Electrical connections ............................................................................15

Variable current output settings ............................................................20

Variable voltage output settings.............................................................21

CAN-bus output option...........................................................................21

Moisture sensor output settings ............................................................21

Digital Display Unit connection ..............................................................22

RS232 connection ...................................................................................24

Software ................................................................................ 25

icountPD Setup Utility software .............................................................25

Microsoft Windows®HyperTerminal connection ...................................28

Communication protocol ........................................................................30

Reference .............................................................................. 35

Contamination Standards.......................................................................35

Viscosity charts.......................................................................................36

icountPD-CAN version, SAE J1939 technical note.................................37

Ordering Information..............................................................................40