Maintenance, Fault Finding and Warranty.

Used correctly, you can expect a long life from a Parker

Torchology Pull-Mig torch, but in order to ensure this

long life, there are a few precautions you should take

note of when using and servicing your torch.

We would recommend that you should pay attention to

the following:

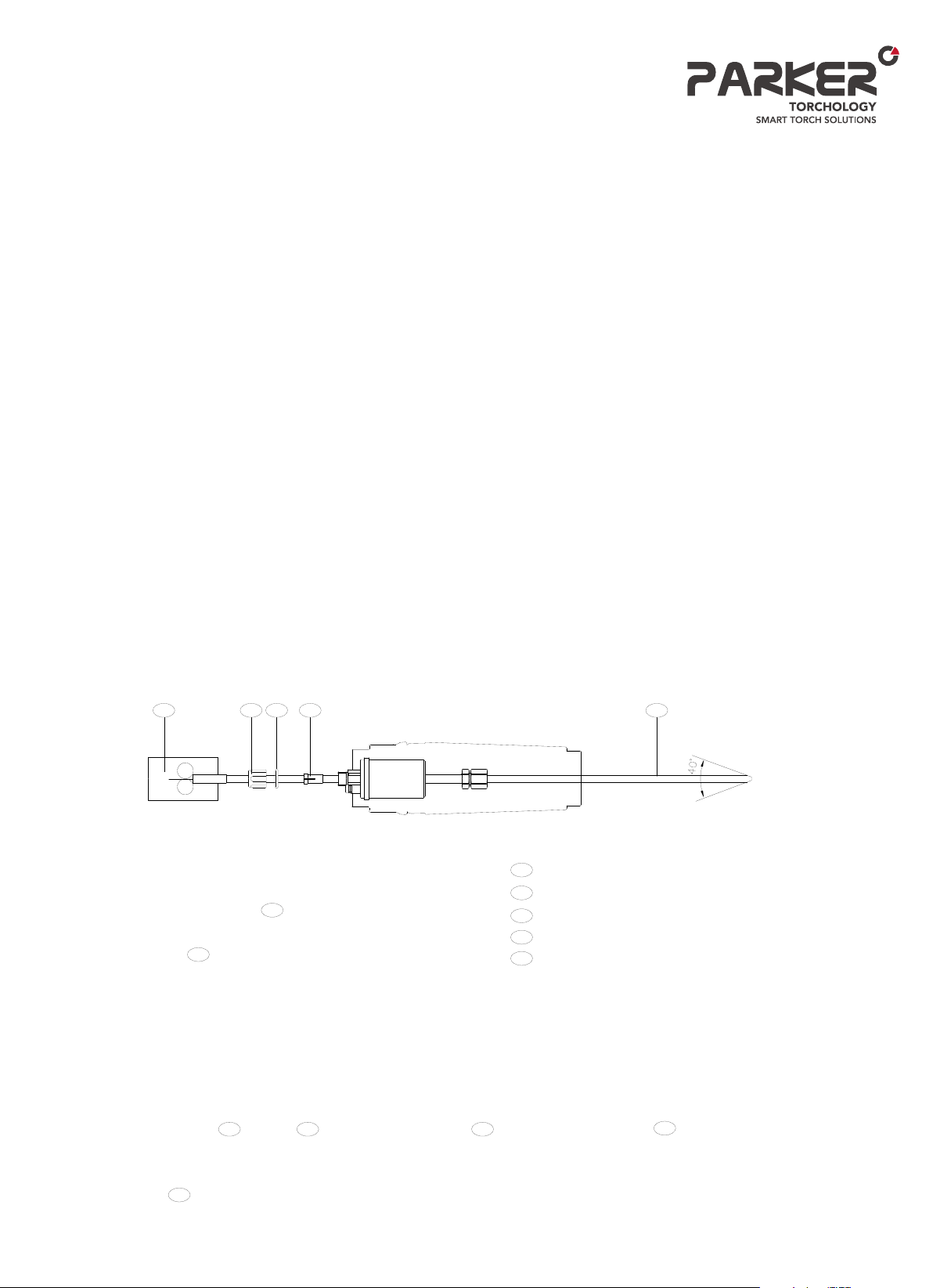

O Ring care

Swan necks are fitted with O-rings to seal both water

and gas channels. The condition of these rings is critical

to the smooth operation of a Parker Torchology Pull-

Mig torch. Damage to these O-rings may affect the weld

performance.

Great care should always be taken when removing or

replacing the neck. Each time the neck is withdrawn from

the body, the O-rings should be inspected. If any wear or

damage is suspected, the O-rings must be replaced.

Any suitable lubricant designed for O-Ring assembly

should always be applied to the O-rings whenever the

neck is removed, or when fitting replacement O-rings.

When applying lubricant,care should be taken not to

block any of the gas or water passage holes.

Front-end consumables

The nozzle, contact tip and diffuser all run at very high

temperatures and you should regularly inspect them

for wear and operational damage. When changing a

contact tip, always use a contact tip spanner to prevent

over tightening. Repeated over tightening will destroy the

threads in the tip adaptor.

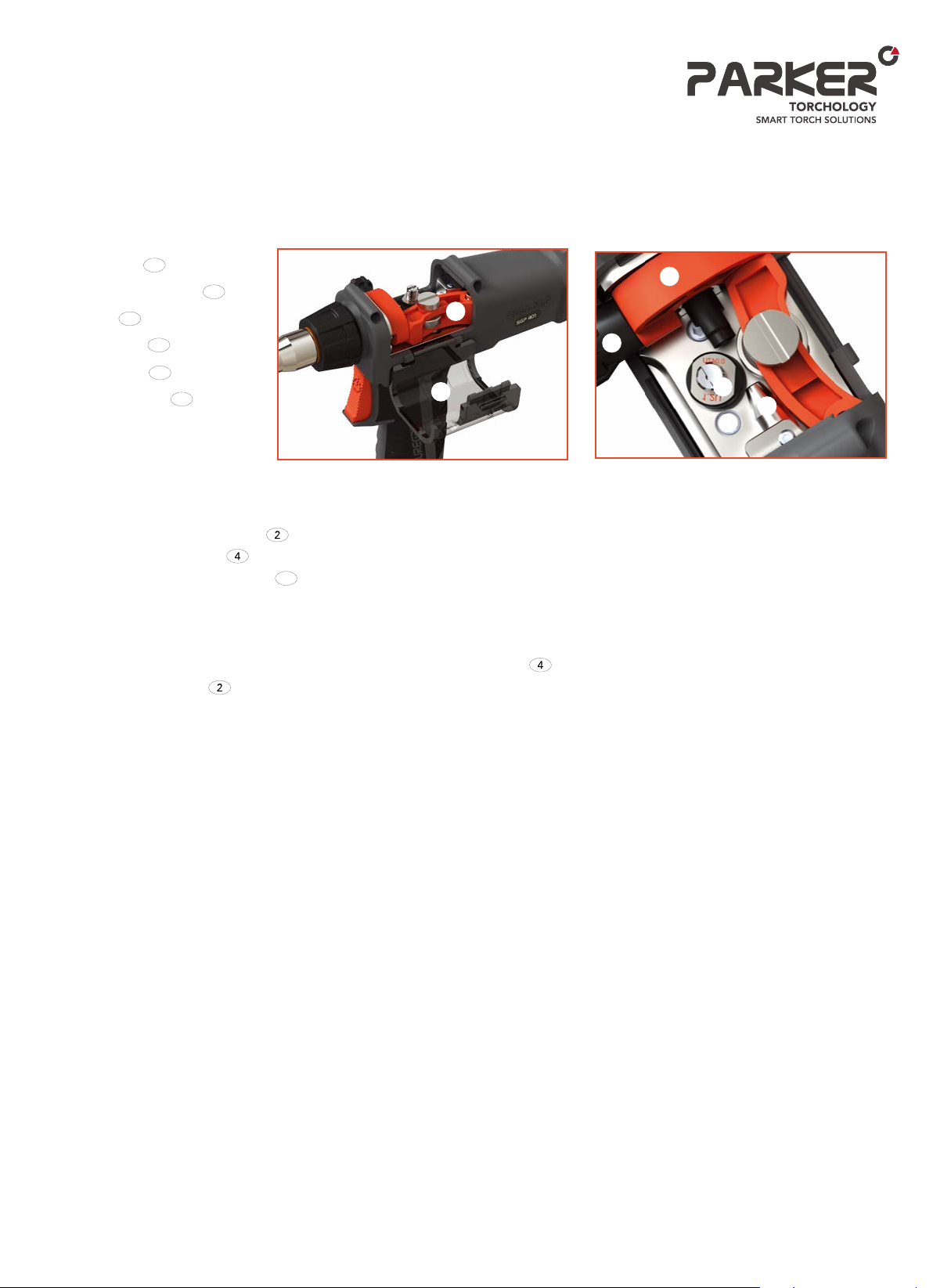

Drive Rolls

Always make sure you have the correct drive roll for the

type and size wire you are using and note that the drive

roll threads are Left-Hand and the drive roll can be

inverted to double its life.

The drive roll and pressure roll should be inspected

regularly for wear. Run the gun in a quiet place, without

wire feeding and listen for any unusual noises. You can

eliminate pressure roll from drive roll noise by releasing

the pressure arm. If you suspect something is wrong,

you should contact your distributor or dealer.

The area around the drive roll should be regularly

dusted off to prevent dust and workshop debris from

accumulating. We do not recommend lubricating the

drive shaft or pressure roll. These are sealed for life

units and lubrication oils or greases will only pick up dust

and turn these oils and greases into a grinding paste. A

simple dust off is all that is required.

The gearbox, drive motor and shaft top bearing are also

sealed for life. No maintenance is required.

Parker Torchology Pull-Mig Warranty

Every Parker Torchology Pull-Mig welding torch is

manufactured to the highest standards and carries a 3

month warranty from the date of sale to the end user. The warranty

covers and is limited to, a fault developing as a result of faulty

workmanship or faulty

materials.

What is covered?

• Defective materials used in the manufacture of the product.

• Faulty workmanship in the manufacture of the product

What is not covered?

• Incorrect use or damage.

• Normal wear and tear to either the product or the

consumables supplied with the product.

• Faults arising from using non-Parker Torchology

spare parts.

• Direct or indirect costs of any form arising as a result of

a suspected, or actual, defective product.

How to make a claim.

This warranty is limited to the original purchaser of the product, it

is not transferable. If a fault is suspected, the dealer or ourselves

must be contacted and informed of the fault before the product is

returned.

You can contact us by

Mail: sales@parkertorchology.com

How will we handle any claim?

Parker Torchology's sales office may ask you to return the product

with a copy of your proof of purchase, (If you are the end-user) or a

copy of proof of sale (If you are a distributor).

Depending on the nature of the claim, we may ask one of our

technical staff to discuss the problem with you to get a quick

resolution.

Once the cause of the problem is established and at our

discretion, we will either repair or replace the defective product

free of charge.

We will refund the costs incurred in returning the product if a

defect is found, but will only refund normal transport costs. We

will not pay for UPS, Express deliveries or any other high speed

carriers.

If we believe the product failure is as a result of any reason other

than defective materials or manufacture, we will issue a written

report to you detailing our findings.

Other issues.

Whilst Pull-Mig welding torches will give long and lasting

service, we do understand the harsh and demanding working

environment in which our products operate, therefore Parker

retain the right to deal with any fault in a manner that best suits

Parker Torchology.

This warranty is an addition to Parker’s standard terms and

conditions and Parker's standard Terms and Conditions of Sale

will take precedence over this warranty.

Maintenance, Fault Finding, and Warranty.

8