8100/8200 Monitor Instruction Manua

1 Introduction

1.1 Manual Conventions

This manua covers the 8100 & 8200 Version 3 Monitors

The manua describes the configuration and operation of the 8100/ 8200 Monitor and inc udes information regarding

sensors. A dimensions stated in this manua are in mi imetres un ess otherwise stated.

The manua has been written on the basis that the user has a basic know edge of instrumentation and an

understanding of the type of measurements being made. Whi st every attempt has been made to ensure that the

instructions are correct, common sense and good engineering practice shou d a ways be used to adapt to specific site

requirements. Training in the use of the 8100/ 8200 Monitor can be provided by Partech, p ease contact sa es for

further information.

1.2 Product Description

The 8100 Monitor is a sing e channe instrument for use with one sensor. It provides a sing e a arm re ay output and a

sing e fau t re ay output. The a arm set point and de ay are configured using contro s mounted on the front pane . The

status of the input channe is indicated by three LED’s.

The 8200 Monitor has two input channe s for use with two sensors. It provides two a arm re ay outputs (one for each

channe ) and a sing e fau t re ay output. The fau t re ay is used to indicate a fau t on either input channe . The 8200

Monitor has two pairs of set point and de ay contro s and two sets of status LED’s. The a arm set point and de ay for

each channe can be independent y set and the status of each channe is indicated separate y.

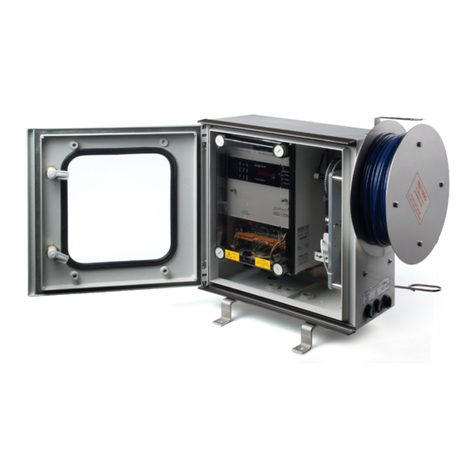

The 8100/ 8200 Monitor has an IP65 rated enc osure and is suitab e for outdoor use, however, a protective cover or

outer enc osure is recommended to further protect the instrument from harsh environmenta conditions.

1.2.1 Options

Part Number Description

163600 8100 Monitor Version 3 (115/230VAC)

171370 8100/8200 Monitor 12VDC Supp y Option

171360 8100/8200 Monitor 24VDC Supp y Option

1.2.2 Compatible Sensors

The 8100/ 8200 monitor can be used with the fo owing Partech sensors:

IR Series IR8, IR15, IR40, IR100

ST Series 0 –1500mg/ , 0 – 10000mg/ , 0 – 30000mg/

1.2.3 Fault Indication

Fau t indication is via the i umination of a status LED that is c ear y visib e on the front pane of the monitor. When

there is a fau t present the orange FAULT LED i uminates.

1.2. Alarm Activation

When the sensor is c ear and not in a fau t condition then the green OK LED is i uminated. If however, the sensor is

obscured or b ocked then the re ay wi enter into the a arm condition and the red ALARM LED wi become i uminated.

1.2.5 Delay Operation

A de ay can be introduced between conditions for an a arm turning on being met and the re ay changing state. At any

time during a de ay, if the conditions for turning the a arm on are removed, then the de ay wi end and the a arm re ay

wi not change state. The de ay can be set between 1 & 90 seconds. The de ay function is in p ace to try to avoid the

occurrence of fa se a arms that may be caused by suspended debris.

168270IM-02 Issue Date 05/01/2010 Page 4 of 14