5

XR1052 / XR939H

Key Features

The helmet has a recessed front for the auto darkening fi lter (ADF) unit covered

by a front visor lens that provides high impact protection suitable for grinding (1B

Impact rated). Both the internal ADF cover lens and front visor lens are easily

changed.

The ADF has a fl ip-up action when a fully clear view is needed.

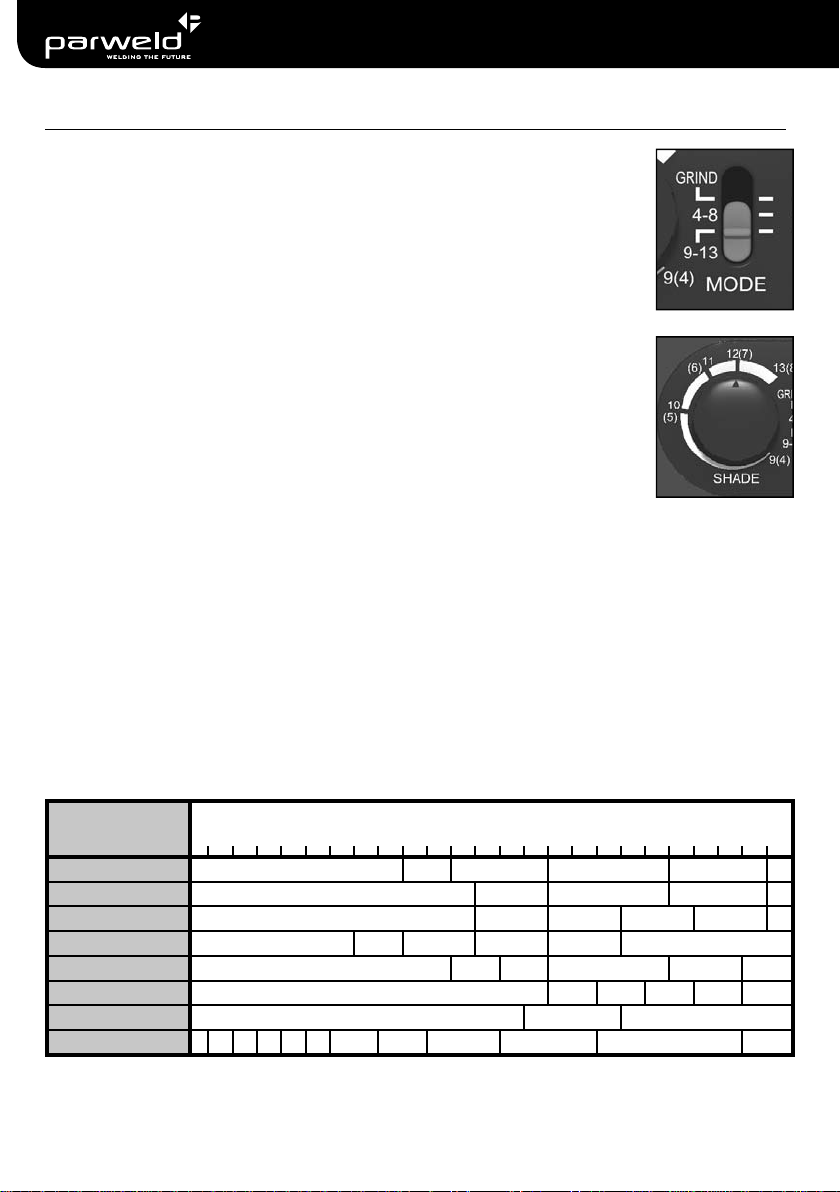

The ADF gives true colour view, light shade of 3 - 3.5 suitable for grinding and has

a full shade level range variable from 4 -13. The sensitivity is adjustable, as is the

delay function. All modes are switchable on the outer control with adjustment dials.

The auto darkening switch function uses four optical sensors mounted in an array

for multi direction and complete space sensing.

The 13 in 1 optical coating provides extremely high UV/IR protection level.

The ADF optics are solar cell powered which has a replaceable lithium backup

battery. A test button feature enables a battery voltage check with an LED light

indicating if low. This button also enables an ADF shading test to check it is function

correctly.

The helmet shell is manufactured from lightweight impact resistant material fi nished

in a mark resistant gloss coating that also resist weld spatter & sparks.

The head gear has multiple rake positions and adjustment for a precise fi t with

comfortable sweatband padding and designed with a special up / down mechanism.

When raised over the head, the headband mechanism positions the center of

gravity low and aligned with the center of welder’s head. This greatly lowers neck

fatigue and make the welder feel more comfortable while working.

At the top of the XR1052 / XR939H helmet shell is fi tted with an air blower system

standard female port for a male hose. Around the helmet perimeter is a head

and neck seal to keep weld fumes out of the helmets internal, breathed clean air,

environment.

The key helmet components fully conform to all relevant international safety

standards, and have excellent full-face, head & neck protection and suitable for

TIG, MIG/MAG, MMA, grinding and plasma processes.

English |