Wireless Optical Dissolved Oxygen Sensor Calibration: See www.pas-

10 013-16057A

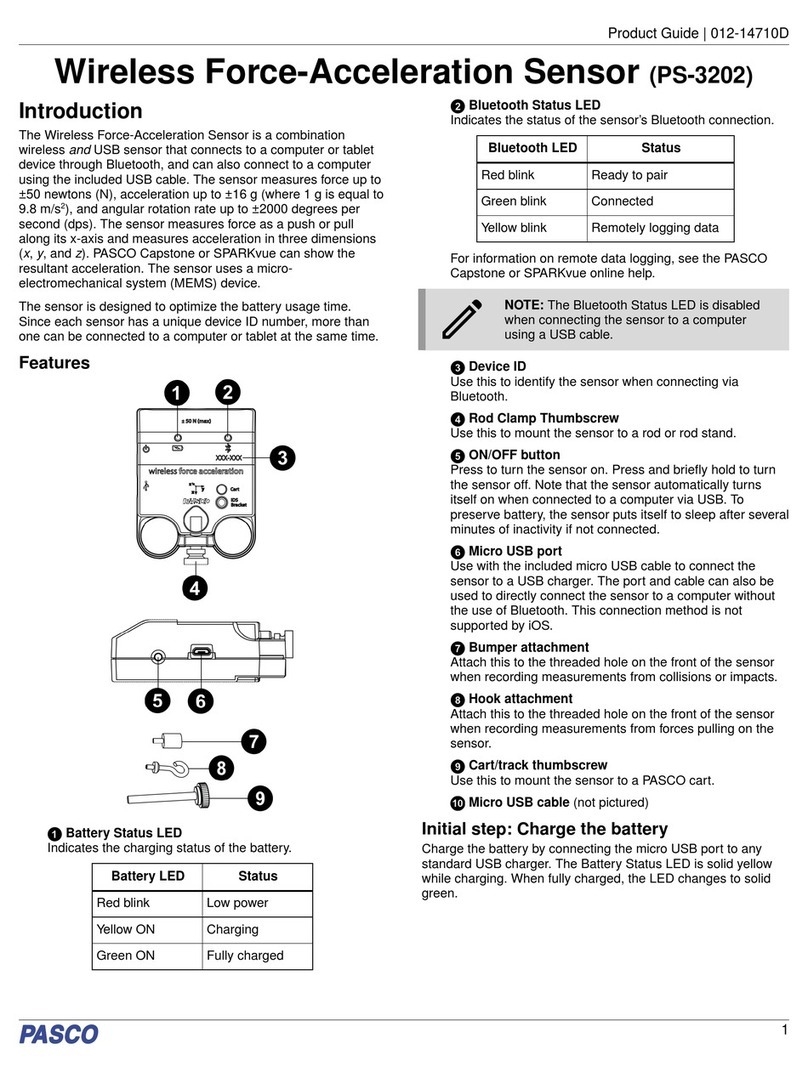

Using the Wireless Optical Dissolved Oxygen Sensor Submerged

Typically, the probe of the Wireless Optical Dissolved Oxygen Sensor would sit

in a beaker of the liquid sample that is being measured. Alternately, the sensor

could be held by a clamp so that the end of the probe is immersed in the

container with the liquid sample. In addition, the sensor is designed to be

submerged for such uses as monitoring water quality in a pond or stream. Turn

the sensor on and pair it with the computing device. Set the sensor so that it will

record in logging mode. (The sensor will not connect wirelessly when

submerged.) To protect the sensor from the liquid sample, screw the transparent

cover firmly onto the top of the sensor. Make sure that the bottom edge of the

transparent cover touches the narrow lip. Remove but do not discard the Rubber

Boot before making a measurement. The sensor is not buoyant so it will sink if

dropped into the liquid sample. Therefore, attach a cable or cord to the eyebolt

at the top of the transparent cover before submerging the sensor. Be careful to

hold the cable or cord securely so that the sensor can be retrieved.

Using the Wireless Optical Dissolved Oxygen Sensor in Air

The Wireless Optical Dissolved Oxygen Sensor probe was specifically designed to be used in water. However,

reasonably good qualitative results may be obtained in air.

The optical dissolved oxygen probes are generally calibrated in 100% air-saturated water or in 'wet' air that is in a

100% relative humidity environment. In either case, the oxygen contribution to the partial pressure of the gas in

'wet' air or in solution is taken to be 20.9%. Given this, it is reasonable to use the probe in a gaseous environment

to measure the oxygen present. The sensor outputs a value labeled “O2 Gas Concentration”.

This value is calculated by taking the DO2 Saturation value from the sensor (100% in air-saturated water or 'wet'

air) and multiplying it by 0.209(20.9%), the assumed partial pressure contribution of O2 in air. For example, if the

DO2 Saturation value from the sensor is 80%, the calculated partial pressure contribution of O2 in air is 80% X

0.209 = 16.7% O2.

Best accuracy will be achieved in high humidity environments. Long term measurements in dry air are not

recommended as this will dry out the probe Sensor Cap and may affect future measurements with the probe.

NOTE: The probe should not be used in an environment with flammable, caustic or corrosive gases.

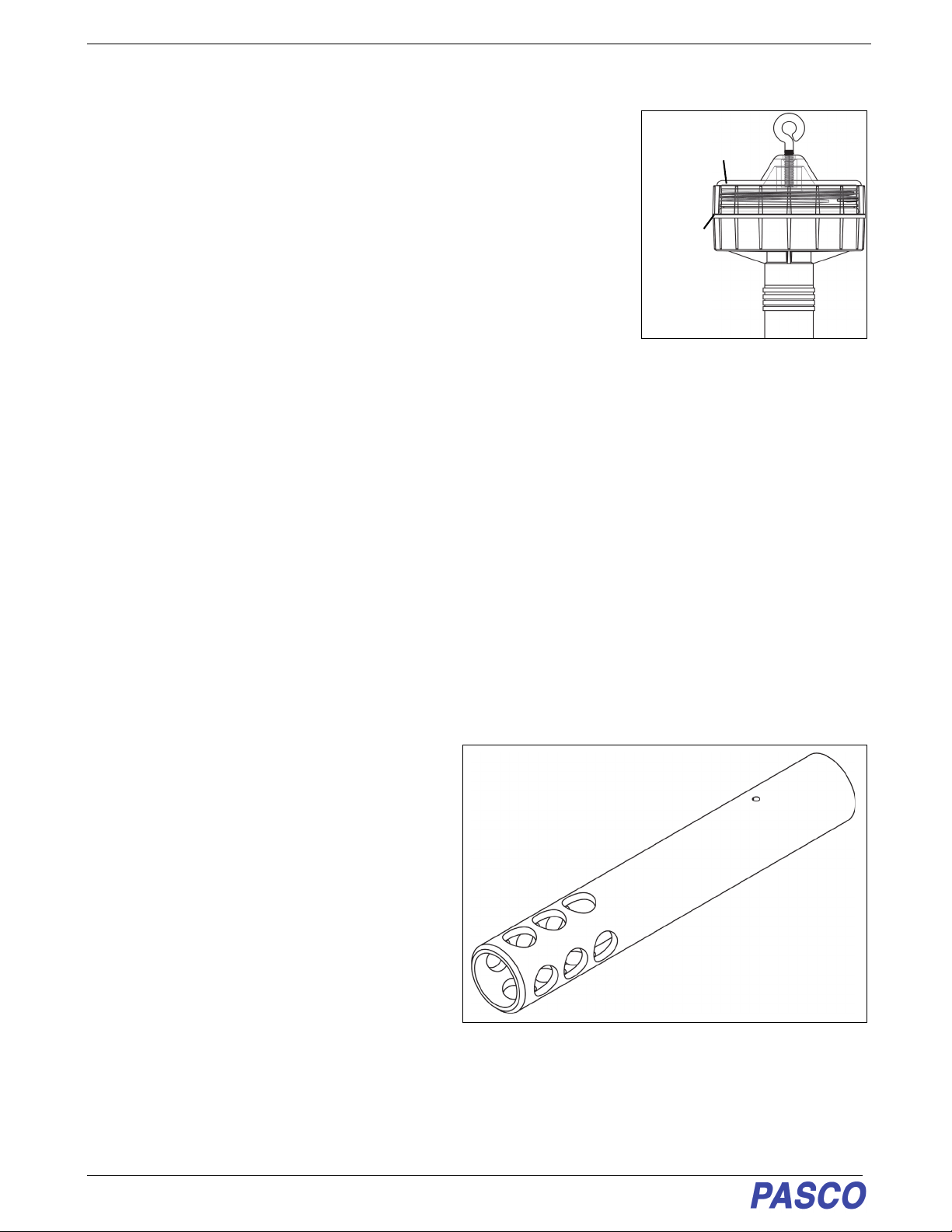

Accessory: Optical Dissolved Oxygen

Probe Guard (PS-3605)

The Wireless Optical Dissolved Oxygen Probe Guard

(PS-3605) is designed to thread onto the probe to

protect the Sensor Cap. It also enables the probe to

sink more rapidly when the probe is immersed in

water.

NOTE: Do not use any tool to thread the Probe Guard

onto the probe. Avoid touching the end of the Sensor

Cap at all times.

Calibration: See

www.pasco.com/calibration

The Wireless Optical Dissolved Oxygen Sensor is calibrated at the factory and does not need to be re-calibrated

under most circumstances. However, if the Sensor Cap is replaced with a new Sensor Cap (PS-3604), then the

Sensor Cap Calibration Code Coefficients (included with the new Sensor Cap) will need to be entered into the

sensor using the PASCO data collection software (PASCO Capstone or SPARKvue). The sensor will then need to

be re-calibrated. (See Replacement Sensor Cap Calibration.)

Narrow

Lip

Transparent

Cover

Wireless Optical Dissolved

Oxygen Probe Guard