®

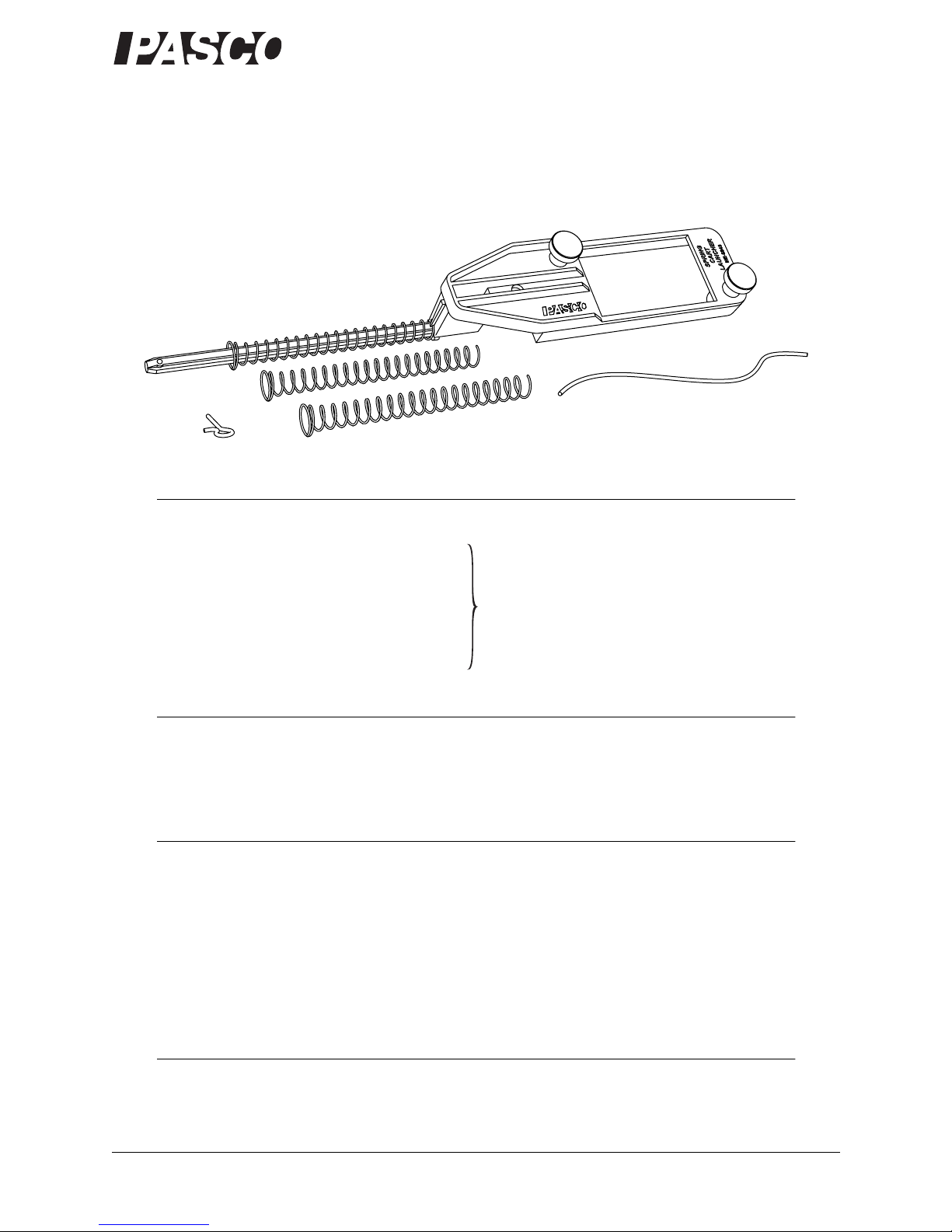

Spring Cart Launcher Sensor-based Experiment

4

Sensor-based Experiment

Note About Sensors and Interfaces

In this experiment, a force sensor measures the force that you apply to the spring; a

motion sensor measures the displacement of the end of the spring as it is compressed,

the position of the cart, and the velocity of the cart.

You can use the PASPORT sensors recommended on page 1 with a multiple-port

interface (such as an Xplorer GLX or Power Link) or two single-port interfaces (such

as USB Links). Most of the measurements described below can also be done with just

one single-port interface using one sensor at a time. ScienceWorkshop sensors and

interfaces would also work.

The instructions below refer to operations in DataStudio software such as connecting

sensors, setting sampling rates, and setting up graphs. For information about these

tasks, press F1 to open DataStudio Help. This experiment can also be done on the

Xplorer GLX in standalone mode (without a computer).

Additional Set-up

1. Follow set-up steps 1 through 3 on page 2.

2. Install one end stop on the track. If you are using a 1.2 m track, place the end stop

near one end. If you are using a 2.2 m track, place the end stop in the middle.

3. Level the track so that the cart does not roll when release from a standstill.

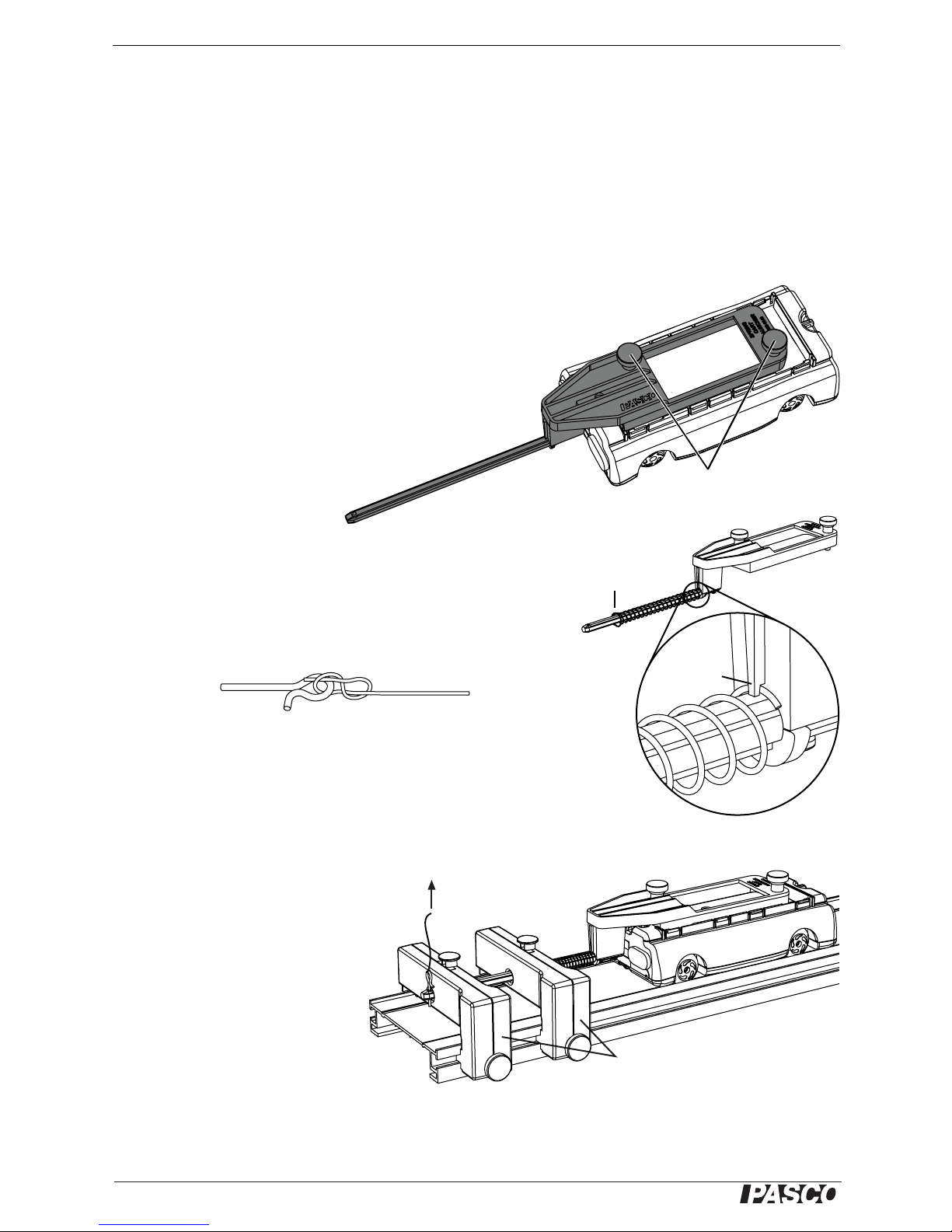

4. Clip the motion sensor to the end of the track opposite from the end stop. Aim the

sensor along the track. Set the range switch to the NEAR or cart setting.

5. Connect the motion sensor and a force sensor to your PAPORT interface (or

interfaces). If you are using a computer, connect the interfaces to it and start

DataStudio.

6. Set the sampling rate of both sensors to 20 Hz.

7. Prepare the following graphs: Position versus Time, Velocity versus Time, Posi-

tion versus Force (Pull Positive).

Spring Constant, Work, and Spring Potential Energy

In this part you will use Equation 1 to determine kfor your spring. The force sensor

measures Fx, and the motion measures x. The slope of the Fxversus xgraph equals k.

1. Place the cart on the track

with the launcher shaft

through the hole in the

end stop.

2. Use a piece of string to tie

the hook of the force sen-

sor to the launcher shaft.

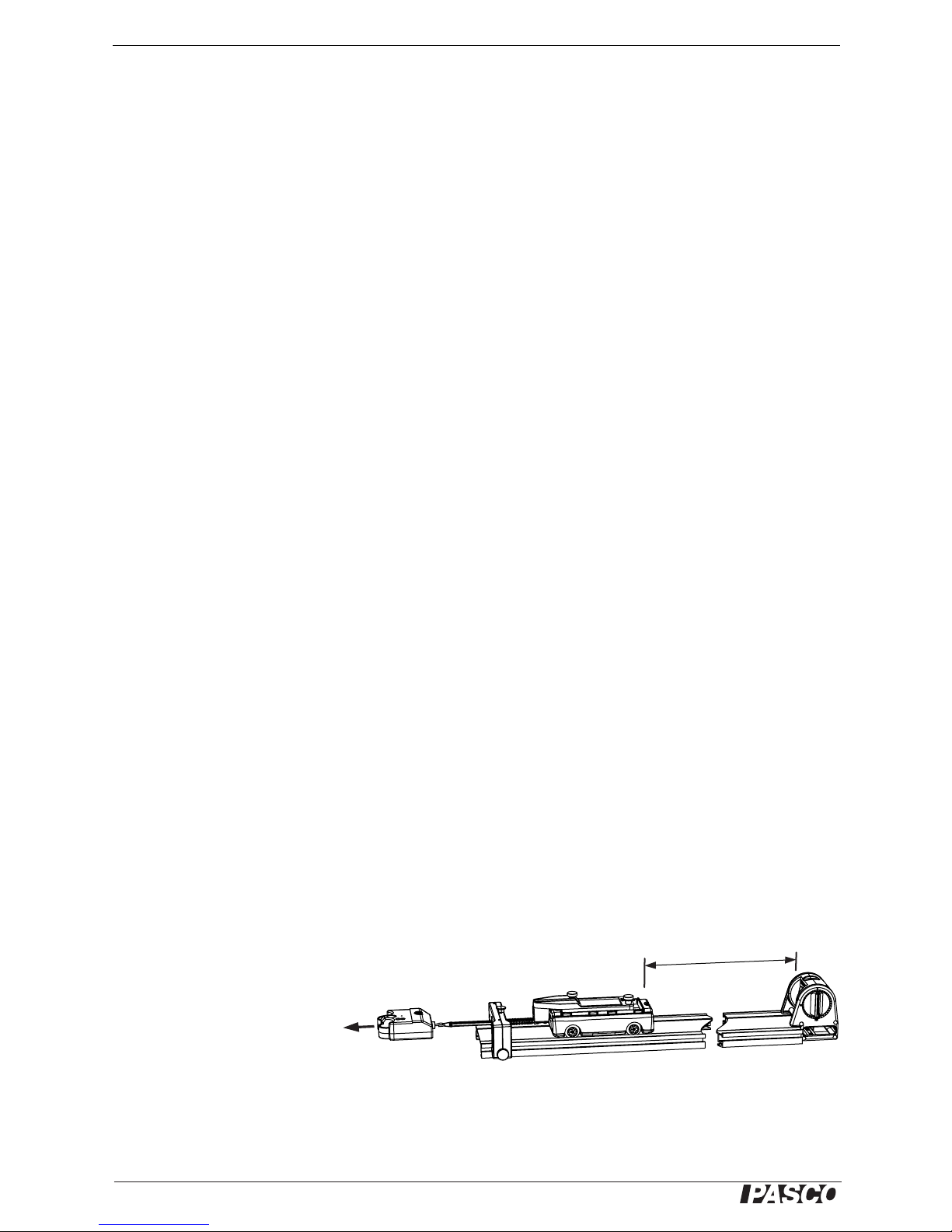

3. Pull back with the force sensor so that the end of the spring just touches the end

stop, but do not compress the spring yet.

~1 m

Pull

Force sensor Motion sensor