Operator's Manual DS 350 / 1319

© PAT Rev. 7 06/18/01 // MO 191319_7.DOC

TABLE OF CONTENTS

1GENERAL INFORMATION........................................................................................ 1

2WARNINGS ........................................................................................................... 1

3SYSTEM DESCRIPTION .......................................................................................... 2

3.1 SYSTEM FUNCTION................................................................................................. 4

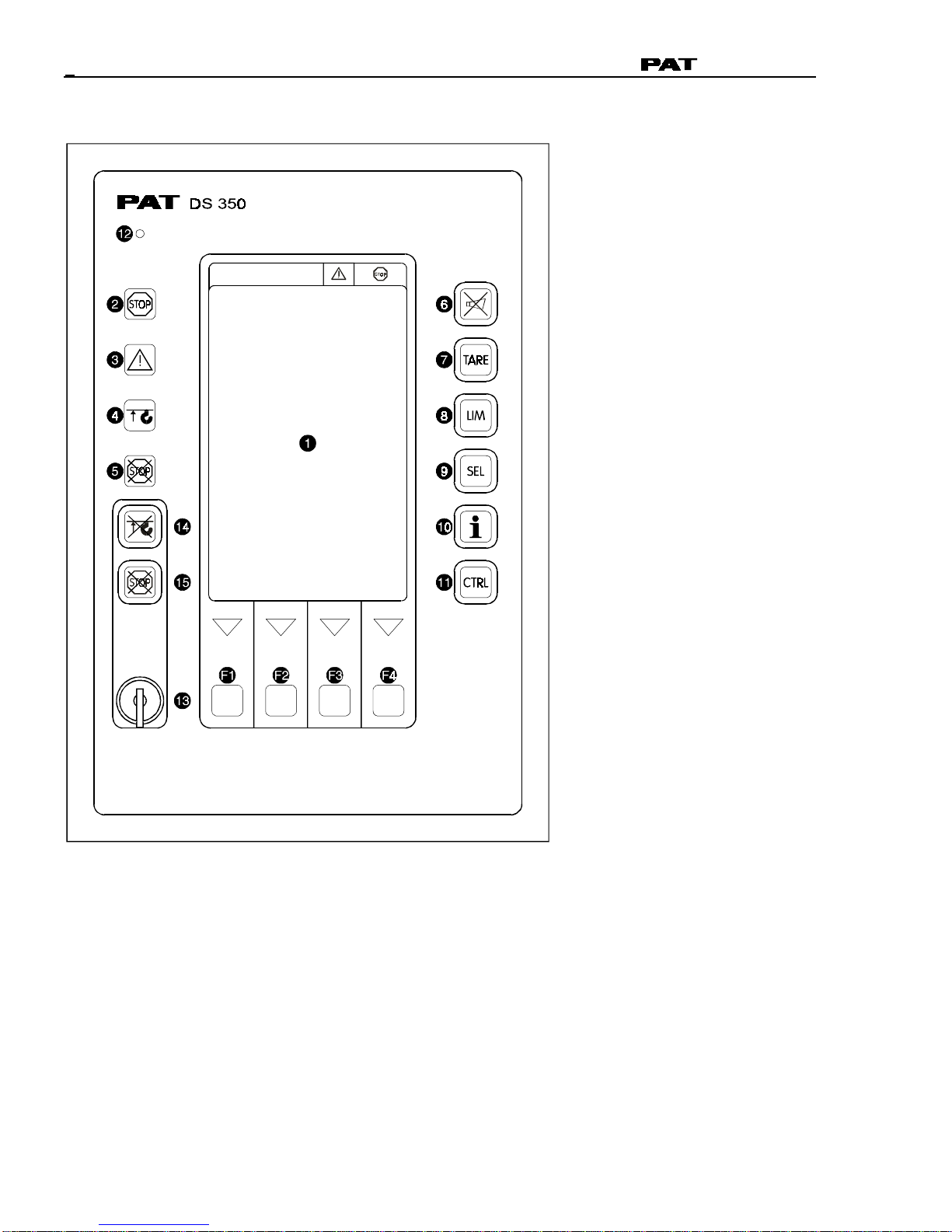

3.2 OPERATING CONSOLE............................................................................................. 5

3.3 CONTROL IDENTIFICATION ........................................................................................ 5

4CONFIGURATION SETUP...................................................................................... 11

4.1 LMI SETUP PROCEDURE........................................................................................ 11

4.2 QUICK SETTING OF THE REEVING ............................................................................. 15

4.3 QUICK HOIST LINE SELECTION................................................................................. 16

5 OPERATION......................................................................................................... 17

5.1 LIMIT SETTING ................................................................................................... 19

5.1.1 Slewing Angle Limitation / Work Area Definition.............................................. 20

5.1.2 Tip Height Limitation ................................................................................... 25

5.1.3 Boom Angle Limitation ................................................................................ 26

5.1.4 Radius Limitation........................................................................................ 28

5.2 INFO CRANE CONFIGURATION ................................................................................. 30

5.3 DISPLAY CONTRAST CONTROL ................................................................................ 31

6PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION ............................ 32

6.1 MACHINES WITH ONLY A MAIN HOIST......................................................................... 32

6.2 MACHINES WITH MAIN AND AUXILIARY HOISTS ............................................................. 32

6.3 INSTALLATION OF ANTI TWO-BLOCK RETAINER IN LOCKING POSITION ................................ 33

6.4 REMOVAL AND STORAGE OF THE ANTI TWO-BLOCK RETAINER ......................................... 33

6.5 PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION ........................................ 34

7 OPERATION......................................................................................................... 36

8SERVICE AND MAINTENANCE............................................................................... 37

9TROUBLESHOOTING ........................................................................................... 38

9.1 GENERAL .......................................................................................................... 38

9.2 MALFUNCTION TABLE ........................................................................................... 38

9.3 OPERATING ERRORS............................................................................................. 39

10 APPENDIX A: DETAILED SYMBOL EXPLANATION OF BOOM EXTENSIONS ............. 40

11 APPENDIX B: DETAILED SYMBOL EXPLANATION OF COUNTERWEIGHT OPTIONS .. 41