C","'+.!#,DB'*+1#B,!

/!0+1!'234!5!!6786986:!88!).)! 67;<766!8!;=666>?@4AB)!

;!

1 GENERAL INFORMATION

The purpose of this service manual is to provide additional information to

assist a service or maintenance person in identifying malfunctions or

system problems with the PAT System. A digital voltmeter and regular

maintenance and service tools will be required to troubleshoot the system.

Note: Knowledge of how to use a digital voltmeter is assumed.

REFERENCE:

Operator’s Manual 056-065-190-005

Calibration Manual 031-300-190-009

Installation Manual 031-300-190-008

SYSTEM MALFUNCTION:

In case of a malfunction of the system, an error code

which identifies the system malfunction will be

displayed in the reeving portion of the display. The

error codes are listed in Section 4, Error Codes. The

table identifies various faults that can occur with

the EI65, explain each fault, and describe the action, which shall be taken

to correct the fault.

Faults within the electronic microprocessor shall be repaired by factory

trained service personnel. When these faults occur, contact your authorized

dealer or service organization.

If the operator identifies a possible problem in the system, perform the

pre-operation inspection Section 5 in the Operator’s Manual 056-065-190-005

to define the problem.

SYSTEM DESCRIPTION:

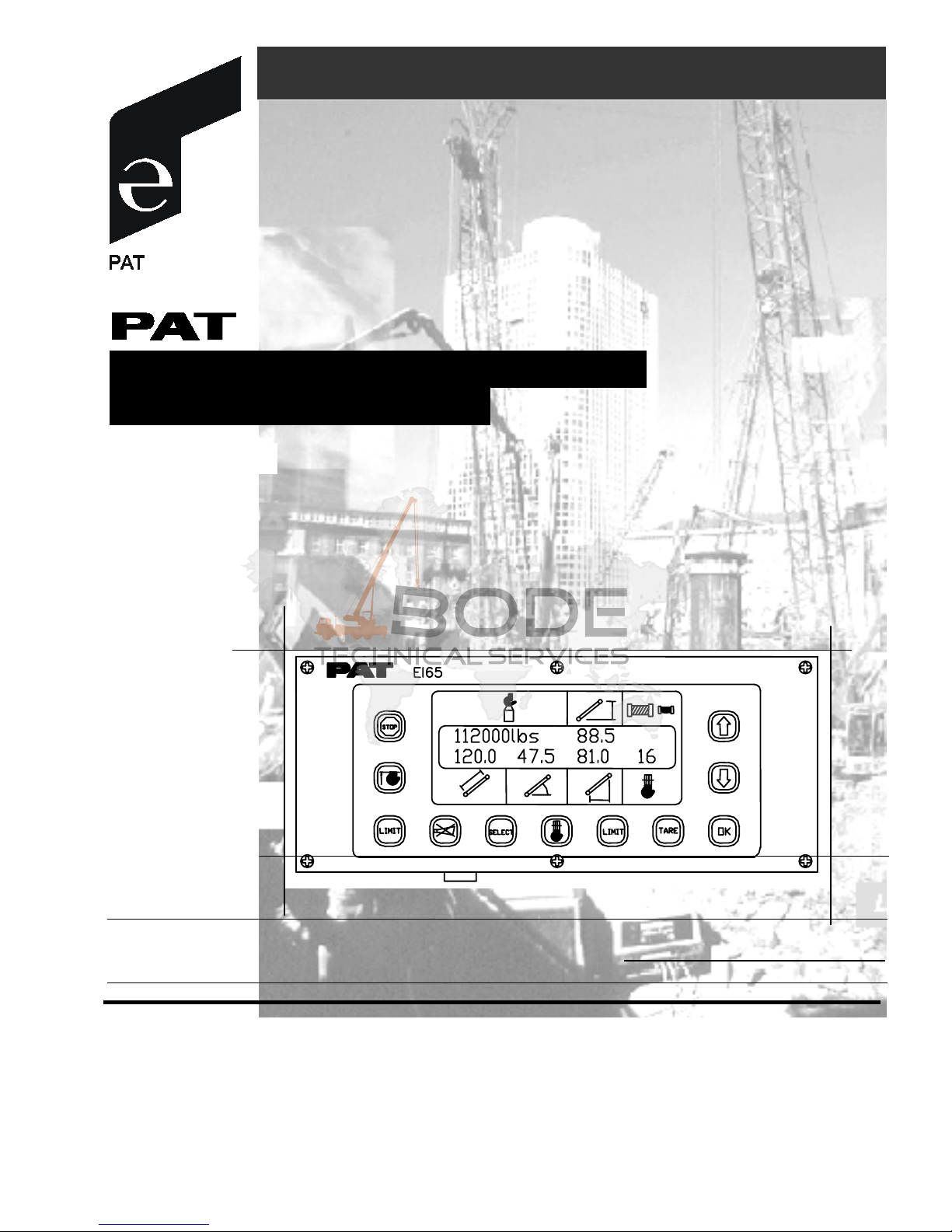

The PAT Length-Angle-Radius-Load Indicator System EI65 has been designed to

provide the crane operator with the essential information required to

enable the machine to be used within its design parameters. The EI65 System

indicates the length and angle of the boom, tip height, working radius and

the total weight being lifted by the crane. Using the various sensors and

the limits set by the operator, the EI65 System warns the crane operator of

certain approaching hazardous conditions which could occur during the

operation of his crane.

WARNING

Always refer to operational instructions and load charts provided by the crane

manufacturer for specific crane operation and load limits.

MB 115.0 J1 85.0

J2 50.0 0J 15.0

E71