Patlite LR6-IL User manual

– 1 –

Notice to Customer

Thank you very much for purchasing our PATLITE

products.

Request the installation and wiring be performed by

a professional contractor if construction work is

involved.

Prior to installation, read this manual thoroughly

before using this product to ensure correct use.

If there are any questions concerning this product,

refer to the contact information at the end of this

document and contact your nearest PATLITE Sales

Representative.

To the Contractor

Read this manual carefully prior to installation.

Be sure to return this manual to the customer.

Signal Tower

TYPE LR6-IL

Complete Operation

Manual

Installation Operation Maintenance

Page

1 Read this First 2

2 Model Number Configuration 2

3 Names and Dimensions 3

4 Installation 4

5 Wiring 6

6 How to Use 7

7 Buzzer Settings 9

8 Detaching the Unit 10

9 Troubleshooting 22

10 Specifications 23

11 Service Parts 25

12 Optional Parts 26

GA0001002_02

– 2 –

1 Read this First

Safety Precautions

The safety precautions that should always be followed in order to prevent injury to user or other individuals as well as

prevent damage to property are described below.

The level of injury or damage caused by ignoring these safety precautions and using the product improperly is categorized

and described below.

Warning This icon indicates an action with the potential to

cause death or serious injury. Caution This icon indicates an action with the potential to

cause injury, physical loss or damage.

Warning

Request the installation and wiring be accompanied by a professional contractor. If installation is done improperly, it

may result in fire, electric shock, falling, or malfunction.

Caution

Adhere to the items below to prevent a short or damage.

- Be sure that the product is disconnected from the power source when changing, replacing or adding a unit.

- Use this product in the proper state. (Replace parts such as the body or each unit if damaged.)

Avoid long exposure to the Buzzer sound from a close distance. Failure to observe this may lead from irritation to

permanent damage to the ears. (When Buzzer Unit is used)

In order to maintain protection of this product against dust and waterproofing performance, be sure to use the head

cover, LED unit and buzzer unit in the condition that it was originally attached.

To ensure the waterproofing performance of this product, do not remove the O-ring or the waterproof packing. Dust

and waterproofing performance will decrease.

When removing covers or packing from the equipment, which is attached to this product, be careful not to snag the

product. Failure to comply may result in damage to the product.

Notice

To ensure proper safety while using the signal tower, observe the following:

- Perform periodic pre-maintenance.

- As a precaution against problems occurring, use this product together with other equipment.

Be sure to prevent electrostatic damage due to discharge when working with this product for wiring, exchanging

units, setting up parameters, etc. by discharging static electricity on your body, etc.

(To prevent damage from static electricity, touch hands or other body parts to metals or an earth ground to discharge

the body from static charge.)

Use a soft cloth, etc., dampened with water to wipe the main unit. If wiped with chemicals outside water (thinner,

benzine, gasoline, oil, etc.), product damage may occur.

To ensure safety when this product is installed onto equipment, observe the following:

-Do not remove parts beyond those designed to be removed from this product.

-Do not modify or disassemble this product.

- Use only the specified replacement parts listed in this document.

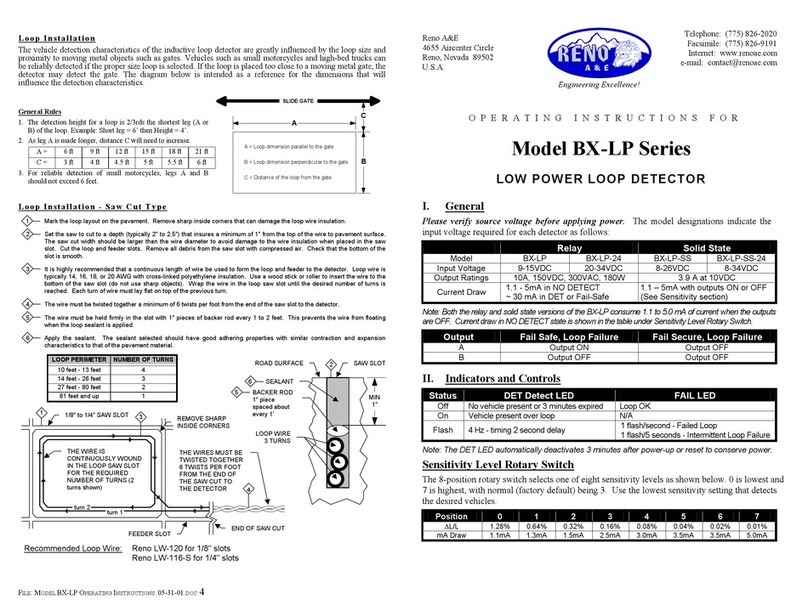

2 Model Number Configuration

Model Tiers

Extended

Functionality

Mounting/

Wiring Buzzer Body

Color

LED Unit

Color

Assembly Model LR 6 - 3 IL WM N W - RYG

Unit Model

(Body Unit) LR 6 - IL WM N W

Unit Model

(Body Unit) LR 6 - IL WC N W

6Φ60 3Tiers

IL IO-Link

WM Direct Mount / M12 Connector (Mounting with 3 Hexagon Bolts)

WC Direct Mount / M12 Connector (Mounting with M30 Nut)

NNo Flashing

WOff-white

LED Color: R (Red) / Y (Amber) / G (Green)

(From top to bottom)

– 3 –

3 Names and Dimensions

WM Direct Mount/M12 Connector Specifications (3-point Screw Attachment)

(Unit: mm)

LR6-3ILWMNW

LR6-ILWMNW

40

19

12

ĭ

ĭ

271

132

19

12

1

2

3

5

6

3

5

6

1

4

4

No. Part Name Material

1 Head Cover PC

2 LED Unit Globe: PC

3 Body PC

4 M12 Bracket PC

5 Direct Mount Bracket PC

6 Waterproof Packing Silicone Rubber

*M12 connector cable is sold separately.

(Please use an M12 connector of Φ16 or less.)

Accessory

LR6 - WM

Flanged nut (M4)

3 pcs.

WC Direct Mount/M12 Connector Specifications (M30 Nut Attachment)

(Unit: mm)

LR6-ILWCNW

ĭ

19

25

ĭ

1

5

6

2

3

4

M30 × 1.5

1/2” NPT Internal

Threads

No. Part Name Material

1 Head Cover PC

2 Body PC

3 M12 Bracket PC

4 Direct Mount Bracket PC

5 Waterproof Packing Silicone Rubber

6 M30 Nut PC

*M12 connector cable is sold separately.

(Please use an M12 connector of Φ16 or less.)

– 4 –

4 Installation

Notice

The following requirements are necessary for a proper mounting location.

- Location with strong and even surface with minimal vibration.

Install with the mounting direction in the upright position.

When the installation location is unavoidably irregular and waterproof performance is required, use a sealant between

the product and the installation surface.

Basic Mounting Instructions

1Make holes for the mounting and wire-distribution for the product.

(Check the Model and refer to the suitable mounting dimension figure.)

2Connect to the product through the distribution hole.

3Secure the product with the nuts.

WM WC Installation Figure (M12 Connector Installation Figure)

Connect to the M12

Connector through the

distribution hole.

Body

M12 Bracket

Direct Mount Bracket

1

2

1Connect cabel

to the M12

Connector.

2Turn the

connected

cable in the

direction of the

arrow.

WM Mounting Dimensional Drawing

(Unit: mm)

120°

120°

ĭ40

Wire Distribution Hole

(Φ20)

Nameplate

Position

Mounting Hole

(3 places)

Screw/

Nut

Φ5M4

Recommended Torque

0.6 N·m

– 5 –

WC Installation Figure (1/2” NPT Installation Figure)

While holding part ‘A’, install the 1/2” NPT.

Failure to comply may result in damage.

AA

Recommended Torque

2.25 N·m

1/2” NPT

Mounting Dimensional Drawing

(Unit: mm)

15°

28.5

Nameplate

Position

Recommended Torque

4.5 N·m

Mounting Hole Nut

Φ31 M30

– 6 –

5 Wiring

Warning

Ensure the proper working voltage is used and that direct current or alternating current is properly applied.

Any mistake in wiring may result in damage or fire.

Caution

Do not pull the wire, or stuff it inside of this product. Possible cause of failure may occur.

Wiring Example and M12 Connector Pin Layout

Wiring Example

L-

C/Q

L+

IO-Link Master

M12 Connecter

L+ (Pin-1)

IO-Link C/Q (Pin-4)

L- (Pin-3)

M12 Connector Pin Layout

N.C.

N.C.

IO-Link C/Q

L-

L+

Connector type: M12, 5-pins, A code

– 7 –

6 How to Use

This product is an IO-Link compliant product.

Connect this product by following the “ 5Wiring” (p. 6).

The controller can light, flash or extinguish the LEDs or control the buzzer.

Changing the “Operating Mode” settings enables the following modes:

Simple Mode

Advanced Mode

Simple Mode

This mode performs simple control by only turning ON and OFF each LED and the buzzer.

Other settings are specified using the parameters.

Send the processed data by referring to the table below.

bit 0 bit 1 bit 2 bit 3 bit 4 bit 5 bit 6 bit 7

Byte 0 data LED Unit (Red)

ON / OFF

Not used Not used Not used Not used Not used Not used Not used

Byte 1 data LED Unit (Amber)

ON / OFF

Byte 2 data LED Unit (Green)

ON / OFF

Byte 3 data LED Unit (Blue)

ON / OFF

Byte 4 data LED Unit (White)

ON / OFF

Byte 5 data Buzzer

ON / OFF

Advanced Mode

This mode performs advanced control such as lighting, flashing, and turning off each LED as well as sounding,

intermittently beeping, or stopping the buzzer.

Other settings are specified using the parameters.

Send the processed data by referring to the table below.

Enable the intermittent buzzer settings to repeatedly sound the buzzer for 500 ms and stop the buzzer for 500 ms.

Refer to (p. 8) for the pattern of each LED.

bit 0 bit 1 bit 2 bit 3 bit 4 bit 5 bit 6 bit 7

Byte 0 data LED Unit (Red)

ON / OFF Not used LED pattern (Red) Not used

Byte 1 data LED Unit (Amber)

ON / OFF Not used LED pattern (Amber) Not used

Byte 2 data LED Unit (Green)

ON / OFF Not used LED pattern (Green) Not used

Byte 3 data LED Unit (Blue)

ON / OFF Not used LED pattern (Blue) Not used

Byte 4 data LED Unit (White)

ON / OFF Not used LED pattern (White) Not used

Byte 5 data Buzzer

ON / OFF Not used

Intermittent

Buzzer

Not used

– 8 –

LED Pattern

Setting Description

0 Lit Example: Byte 0 data = 01h Red Light

Byte 1 data = 11h Amber Flashing

(1 sec Cycle)

Byte 2 data = 31h Green Flashing

(250 ms Cycle)

Byte 3 data = 61h Blue Triple

Flash

Byte 4 data = 00h White OFF

Byte 5 data = 11h Intermittent

Buzzer

1 1 sec. Flash (Slow)

2 500 ms Flash (Medium)

3 250 ms Flash (Fast)

4 Single Flash

5 Double Flash

6 Triple Flash

Notice

Settings 4, 5 and 6 cannot be used with the Multicolor LR6-E-MZ of the LED Unit.

Each LED may not light correctly.

Settings 4, 5 and 6 cannot be used with the WD transmitter for the wireless data communication system.

The correct data may not be acquired.

The intermittent buzzer and the LED pattern do not synchronize.

Parameter Settings

For information about the parameter settings, please download the IODD from the LR6-IL page on our homepage (https://

www.patlite.com/).

Please also download and use the parameter sheet in the same way.

– 9 –

7 Buzzer Settings

Caution

Do not use excess force when performing operations. Failure to comply will result in damage due

to breakage or deformation.

Do not use sharp-pointed objects to perform operations. Failure to comply may result in damage

and inoperative switches or hinder contact between contact parts.

Buzzer Unit

Bottom View

■Indicates the position of the DIP

switch. (Down to turn “ON”.)

DIP Switch Configuration Table

Buzzer

Sound

DIP Switch Sound Pattern DIP Switch Volume

12 3

No. 1 OFF OFF Rapid intermittent beep

(call sign) OFF Normal

No. 2 ON OFF Continuous beep sound ON Noise reduction

No. 3 OFF ON Rapid hi-low

Note: DIP Switch 4 is not used.

The factory default settings have all of the DIP

switches in the “OFF” (Up) position.

No. 4 ON ON Sweep sound

– 10 –

8 Detaching the Unit

Follow the procedure below to detach a unit, such as when removing the Buzzer Unit or changing the layout of the LED

Units.

Link to Video

Caution

Be sure that it is disconnected from the power source before working on it.

Do not apply excessive torque or strong shock to each unit or body. Failure to comply will result in damage or

malfunction.

Do not touch the connector area or the inside of the body and LED unit. Failure to comply will result in damage or

malfunction.

Be sure to lock each unit securely when attaching. Failure to comply will result in damage or malfunction.

Detach the unit in the following manner. Any other method may result in damaging the product.

Attachment: Attach one unit at a time to the body.

Removal: Firmly hold the bottom section while removing the upper section.

Please attach each unit

from the Body Unit one at

a time.

Units may become

damaged if attached from

the top side.

Notice

The maximum number of attachment units per product are five LED units, plus one buzzer unit.

When using the Multi-Color LED Unit LR6-E-MZ for the LR6 (60 mm) Signal Tower, the maximum number of attachment

units per product is one LED unit and one buzzer unit.

When using Wireless Data Acquisition System WD, the maximum number of attachment units per product are three

LED units.

– 11 –

<LED/Buzzer Unit>

Removal

Turn the body or LED unit counter-clockwise to unlock,

then raise upwards to remove it.

Positioning Mark

<Locked> <Unlocked>

LED Unit or Buzzer Unit

Body or LED Unit

Attachment

Align the positioning marks

after attachment.

Positioning Mark

<Unlocked> <Locked>

Align the Positioning Mark after insertion, then turn the

unit clockwise to lock it.

– 12 –

<Body Unit>

Removal

While holding the Direct Mount Bracket, turn the M12

Bracket counter-clockwise, until it unlocks, then pull it

upwards to remove.

Positioning Mark

<Locked> <Unlocked>

M12 Bracket

Direct Mount

Bracket

Attachment

Align the positioning marks

after attachment.

Positioning Mark

<Unlocked> <Locked>

Align the Positioning Mark after insertion, then turn the

unit clockwise to lock it.

– 13 –

<Troubleshooting the Buzzer Unit Attachment>

The Buzzer Unit is generally in the status shown in the diagram below after removal.

Groove

Rib

Buzzer Unit

(Detached)

Bottom View

Positioning

Mark

Buzzer Unit

LED Unit

Body

The rib inside of the Buzzer Unit fits into the groove when the

Buzzer Unit has been removed from the product.

Caution

Check to make sure the rib inside of the Buzzer Unit fits into the groove if the Buzzer Unit does not attach properly. Attach

the Buzzer Unit by referring to the next page if the rib does not fit into the groove as shown in the diagram below.

In addition, the rib may slide out of the groove during removal as shown in the diagram below depending on how the

Buzzer Unit was removed.

Attaching the Buzzer Unit to the product again in this state may result in damage.

Buzzer Unit

Bottom View

Groove

Rib

– 14 –

Use the procedure below if the Buzzer Unit does not attach properly.

Groove

Rib

Turn the part inside the Buzzer Unit in the counter-clockwise direction.

Turn until the rib fits into the groove, then attach the Buzzer Unit to the

product.

Buzzer Unit

Bottom View

Turn this part in the

counter-clockwise direction.

– 15 –

<Example for LED Unit Reconfiguration>

Moving an LED Unit lower

1 Remove the LED Unit right above the LED

Unit in the area to remove.

3 Align the positioning marks and insert the LED

Unit that was removed in 1, then turn the

LED Unit clockwise to lock it in place.

2 Turn the LED Unit to remove counter-

clockwise while holding the adjacent LED unit

to release the lock, then pull upward.

– 16 –

Adding an LED Unit

1 Remove the LED Unit above the area to

attach an additional LED unit.

3 Align the positioning marks and insert the LED

Unit that was removed in 1, then turn the

LED Unit clockwise to lock it in place.

2 Align the positioning marks and insert the

LED Unit, then turn the LED Unit

clockwise to lock it in place.

– 17 –

Changing the Position of an LED Unit

1 Remove the LED Unit right above the

LED Unit that will be changing postitions.

3 Remove the LED Unit right above the

position to add the LED unit.

2 Remove the LED Unit that will be changing

positions.

4 Attach the LED Unit that was removed in 2.

– 18 –

5 Attach the LED Unit that was

removed in 3.

6 Attach the LED Unit that was

removed in 1.

– 19 –

<Troubleshooting the LED Unit>

The structure of the LED Unit is indicated below.

Status Condition

LED Unit

Body LED Unit

(Detached)

Top View

Lens

Rib/Groove

Rib/Groove

Positioning

Mark

The rib of the lens generally fits into the groove when the LED Unit has been

removed from the product.

LED Unit

Body

LED Unit

(Detached)

Top View

Lens

Groove

Rib

Groove

Rib

Positioning

Mark

The rib of the lens generally does not sit in the groove while the LED Unit is

attached to the product.

– 20 –

Caution

Check whether the rib of the lens inside of the LED Unit fits into the groove if the LED Unit does not attach properly. Attach

the LED Unit by referring to the next page if the rib does not fit into the groove as shown in the diagram below.

In addition, the rib may slide out of the groove during removal as shown in the diagram below depending on how the LED

Unit is removed.

Attaching the LED Unit to the product again in this state may result in damage.

LED Unit

Top View

Lens

Groove

Rib

Rib

Groove

Do not remove the LED unit as shown in below.

The rib of the lens will slide out of the groove.

Attaching the LED Unit to the product again in this state may result in damage.

1 Remove multiple

LED units at the

same time.

2 Remove the target LED

Unit from the multiple

LED Units that have

been removed.

The rib of the lens slides

out of the groove.

Table of contents

Popular Security Sensor manuals by other brands

INFRARED CAMERAS

INFRARED CAMERAS SOUND DETECTAI user manual

ABB

ABB Busch-Watchdog 70 MasterLINE operating instructions

Orbis

Orbis EBR-2 Instructions for use

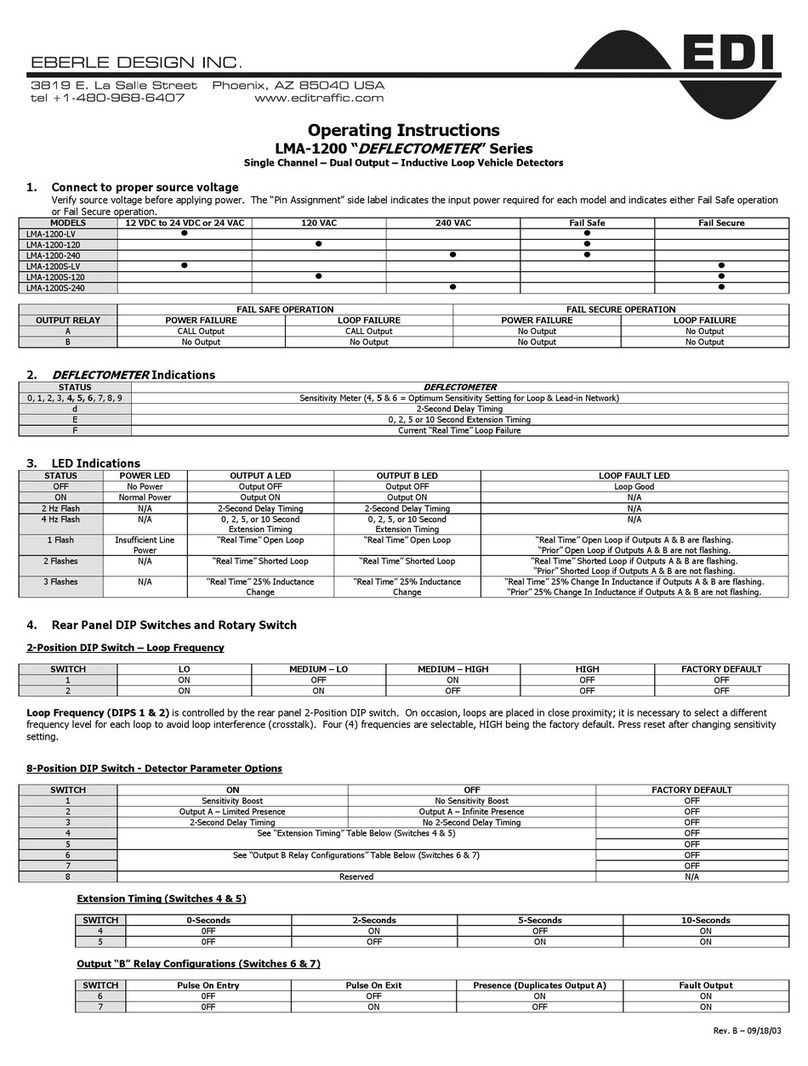

Eberle Design

Eberle Design LMA-1200-120 operating instructions

Honeywell

Honeywell Satronic IRD 1010 manual

Redwall

Redwall V Series installation instructions

Bosch

Bosch ISN-SM-50 installation manual

Bosch

Bosch Truvo Original instructions

Innotech

Innotech FSG 01 Instructions for installation and use

Midland

Midland Rupture Disc Device Operation Inspection and Maintenance

Interlogix

Interlogix AP633A installation instructions

merten

merten ARGUS 110 Basic operating instructions