PATTI QUANTUM Series User manual

PATTI®

Pneumatic Adhesion Tensile Testing Instrument

QUANTUM

SERIES

OPERATOR'S MANUAL

(OLD

OLD MODEL)

PATTI®

Pneumatic Adhesion Tensile Testing Instrument

QUANTUM

SERIES

OPERATOR’S MANUAL

(OLD

OLD MODEL)

MODEL PATTI® QUANTUM_____________

SERIAL NUMBER______________________

SOFTWARE VERSION__________________

SALES REPRESENTATIVE______________

DATE OF DELIVERY___________________

WARRANTY EXPIRATION DATE________

TABLE OF CONTENTS

Instrument Description............................................................................................................1

Cross-Sectional Schematics of Piston Assemblies..................................................................2

Safety Precautions...................................................................................................................3

Initial PA I® QUANTUM GOLD Software Installation Procedure*..................................5

PA I® QUANTUM GOLD Operation Procedure

I. Pre- est Preparation..............................................................................................7

A. Pull Stub Attachment...............................................................................7

B. Cross-Sectional Schematics of Pull-Stub Adhered o Coating...............8

C. PA I® Connection Illustration............................................................10

D. Control Module Layout Illustrations.............................................11 & 12

E. Instrument Preparation............................................................................13

II. est Procedure....................................................................................................15

A. Control Module- est Surface Interfacing..............................................15

B. Control Module Operation.....................................................................16

C. PQGold Software Screenshot and Quick Reference Guide...................17

D. PQGold Software Suite Pre- est Setup.................................................18

E. PQGold Software Suite Post- est Operation...................................19 (5)

i. USB Camera Photo-documentation Procedure...................20 (8b)

ii. Generating a Report of the Pull- est....................................21 (8c)

*ONLY NEEDED IF ATTEMPTIN TO INSTALL THE PQ OLD SOFTWARE ON A

COMPUTER OTHER THAN THE ONE INCLUDED IN YOUR PACKA E!

TABLE OF CONTENTS (cont')

III. Post- est Instructions.........................................................................................22

A. Preparing for further testing..................................................................22

B. Close-out Procedure..............................................................................22

C. Analysis (for those not using PQGold Software Suite).........................23

Appendices

Frequently Asked Questions (FAQ) [Appendix A]....................................................25

Initial Bluetooth Configuration Instructions* [Appendix B].....................................27

AS M D4541 (page 1 included) [Appendix C].........................................................28

Piston Conversion able(s).........................................................................Appendix D

(reference only; software performs calculation)

Warranty & Warranty Registration..............................................................Appendix E

PQGold Software*..................................................................................Rear Binder Pocket

Software Quick Reference Sheet.........................................................................Rear Cover

*ONLY NEEDED IF ATTEMPTIN TO INSTALL THE PQ OLD SOFTWARE ON A

COMPUTER OTHER THAN THE ONE INCLUDED IN YOUR PACKA E!

INSTRUMENT DESCRIPTION

he PA I® system applies a true axial (relative to stub axis) tensile pull test. he tensile values

obtained quantitatively measure the bond between a paint, film, coating or adhesive and the substance

substrate. he PA I® conforms to AS M D4541, “Pull Off Strength of Coatings Using Portable Adhesion

esters,” and is listed in Annex A.4 as the only self-aligning, pneumatic instrument. he surface to be tested

can be smooth, rough, porous, flat or even curved and bond strengths of up to 10,000 psi can be tested with

the PA I® (using the F-20 piston). Advances in PA I® technology have been mainly customer-driven, so

custom applications are not only welcomed, but encouraged.

In a typical test, the first step is to properly attach a “pull-stub” to the test surface. Once the pull-stub

epoxy has cured, a self-aligning piston is attached to the pull-stub (see illustration on opposite page). he

control module is supplied with pressurized gas and then connected to the piston via a hose. he user slowly

increases the pressure to the piston until separation occurs between the pull-stub and the coating/test surface

(or until some predetermined pressure is reached). he control module will indicate the maximum pressure

applied to the piston, with or without pull-stub detachment. his burst pressure is then converted into tensile

strength (psi) by consulting a table for the appropriate piston and pull-stub. It is recommended that at least

three pull-tests are performed and statistically compared for a given surface before a definitive pull-off

pressure is assumed.

1

2

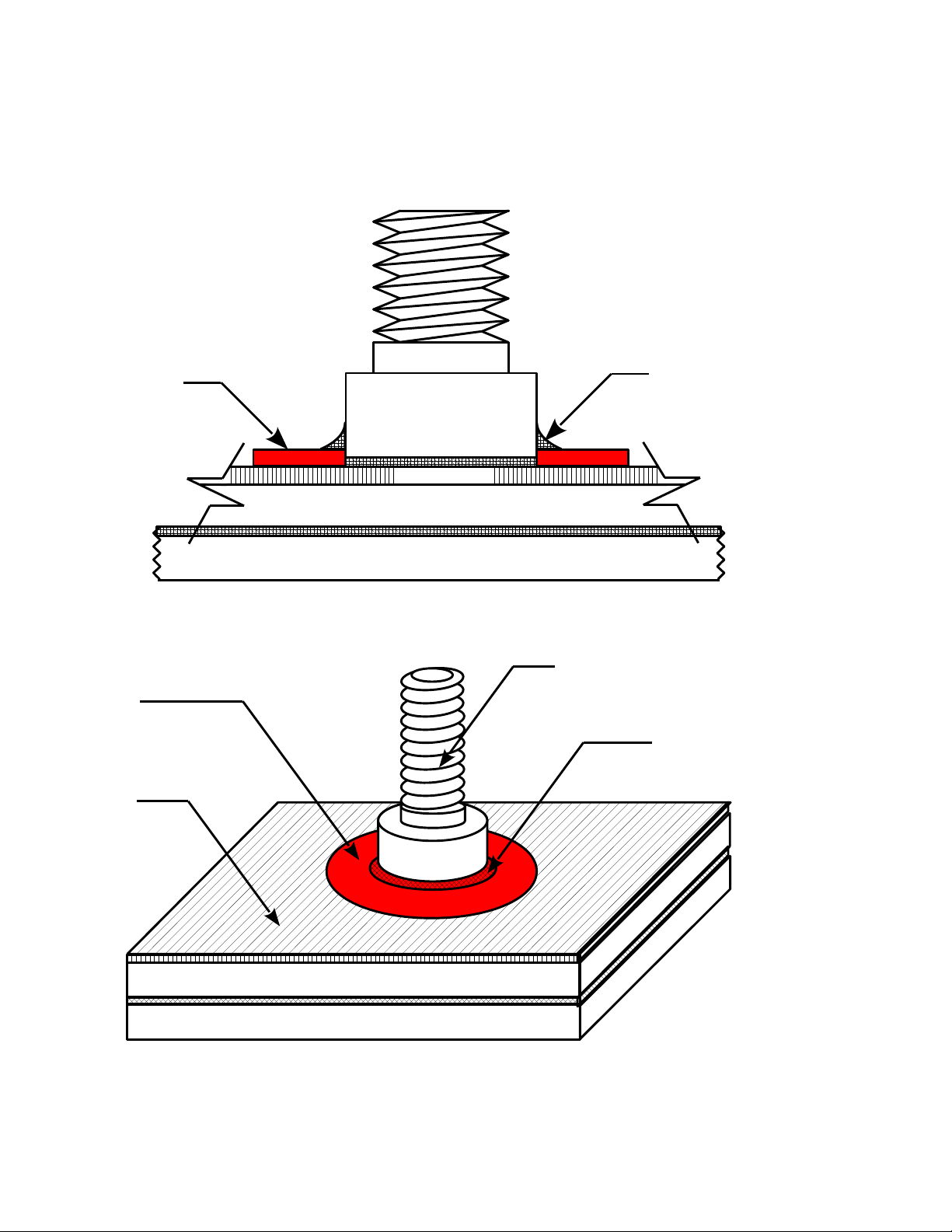

COATIN

SUBSTRATE

PULL-STUB

ASKET

ASKET

REACTION PLATE

ALL-THREAD ROD

KNURLED-KNOB

STAND-OFF RIN

(MAY DIFFER

FROM PICTURE)

PISTON BODY

PISTON PRESSURE

HOSE (BLUE)

ADHESIVE

STRAI HT CENTER HOLE

(NOT THREADED)

ASKET

CROSS-SECTIONAL SCHEMATICS

OF SELF-ALI NIN PISTON ASSEMBLIES

PULLIN FORCE REACTION PLATE

WITH THREADED

CENTER HOLE

PULL-STUB

COATIN

SUBSTRATE

PISTON

PRESSURE

HOSE

(BLUE)

ASKET

FI URE 1: STANDARD PISTON ASSEMBLY

FI URE 2: CONCRETE PISTON ASSEMBLY

PULLIN FORCE

SAFETY PRECAUTIONS

●Pull-Stub attachment

○Always follow the epoxy/adhesive manufacturer's instructions.

○Use latex gloves while mixing and applying adhesives to the test surface to avoid contact between

the adhesive and bare skin.

○A well-ventilated area is recommended when handling uncured adhesives.

●CO2 cartridges

○Keep cartridges out of direct sunlight.

○Do not expose cartridges to temperatures above 49 °C / 120 °F.

○Never dispose of full cartridges.

○Do not attempt to remove the CO2 cartridge holder from the control module if a CO2 cartridge is

installed in the holder and supply pressure gauge does not indicate 0 psi. Doing so will result in

rapid depressurization of remaining CO2 in cartridge!

●Prior to testing

○Safety goggles are recommended during each and every test.

○Do not apply pressures in excess of 150 psi to the supply air inlet.

○urn on the control module and ensure that the display indicates 0 psi (+/- 1 psi) before attaching

the blue piston hose to the piston outlet connection on the control module.

○Ensure that hose connections have been fully threaded or seated prior to performing a test.

●During testing

○Stand clear of the piston after it has been attached to the pull-stub due to the high pressures

present.

○Never attempt to open the control module as high pressures may be present. No internal user

adjustments are needed.

●After testing

○Do not attempt to remove the piston or any of the hose connections without properly

depressurizing the system according to the instructions in this manual.

●Battery precautions (9V and/or Laptop Battery)

○Do not store batteries in the control module if the unit will not be used for a long period of time.

○Do not dispose of in fire.

○Never attempt to short circuit or disassemble.

○Do not use if leakage is detected.

○Recycle or dispose of used batteries properly.

3

4

PATTI® QUANTUM OLD SOFTWARE INSTALLATION PROCEDURE

ONLY NEEDED IF ATTEMPTIN TO INSTALL THE PQ OLD SOFTWARE ON A

COMPUTER OTHER THAN THE ONE INCLUDED IN YOUR PACKA E!

System Requirements:

●Microsoft Windows enabled machine with Microsoft 2000 or later Operating System

(may not be compatible with Windows Vista)

●500 MB free Hard Drive space

●1 available USB port for basic operation (2 required if connecting the unit to your

computer via USB while using the USB camera simultaneously)

●OP IONAL: native Bluetooth capability or third party Bluetooth Dongle

(may be sold separately)

1. Identify the humb Drive that was packaged with your PA I® Quantum Gold. Insert it into a

USB port on your computer. Exit any other programs that are currently running.

Go to the Start menu and select My Computer. Double-click on the humb Drive folder labeled

PQ old vxxx. Navigate through the Installer folder and the Volume folder to double-click on

setup.exe to run the installer. It is recommended that you allow the software to install the

components in the default locations. Otherwise the App may not be able to find called

components when needed. Click Next.

2. Read and accept the National Instruments License Agreements. Click Next.

3. Wait for installation of the National Instruments software to complete. Note that this may take

20 minutes or longer depending on the speed of your computer.

Click Finish to exit the National Instruments Installer.

5. If you are using Windows XP and the USB camera drivers do not install automatically, locate

the MicroCapture folder on the humb Drive and click on setup.exe. Follow the steps

presented. he drivers will be automatically installed on Windows 7 machines.

6. Once you install this software package on another computer, you will need to register the ActiveX

controls to enable the imaging properties of the USB microscope. o do this, perform the

following steps (Windows 7):

a. Click start and type cmd in the search box. Do not press enter afterward.

b. In the window that appears, right-click on cmd.exe and choose Run as administrator.

c. Once at the command prompt, type the following exactly:

regsvr32 "C:\Program iles\P.A.T.T.I. Quantum Gold\data\IVDX.ocx"

hen press EN ER. You should receive a notification that the control was registered

successfully. If not, check the path by attempting to navigate to the control on your hard

drive.

5

PATTI® QUANTUM OLD SOFTWARE INSTALLATION PROCEDURE

d. Again, at the command prompt, type the following exactly:

regsvr32 "C:\Program iles\P.A.T.T.I. Quantum Gold\data\CamViewITaddons.ocx"

then press enter. you should receive a notification that the control was registered

successfully. if not, check the path by attempting to navigate to the control on your hard

drive. close the command prompt window.

7. Determine which COM Port your computer will use to communicate with the PA I®

Quantum Gold Control Module:

a. Go to the Start menu. Right-click on My Computer select Manage.

b. In the left-hand directory, left-click Device Manager to bring the contents into the

right-hand directory.

c. In the right-hand directory, click on the + sign next to Ports (COM & LPT) to expand

the contents of the directory.

i. o use the included USB--> RS232 Cable, look for the COM Port number that

corresponds to the selection titled Prolific... and record it for use later.

ii. o use Bluetooth (wireless data transmission) you may note the COM Port

number that corresponds to the selection titled Bluetooth Serial Port. However,

there are other settings that need to be configured properly to use Bluetooth. If

you are having problems connecting via Bluetooth, consult the Initial

Bluetooth Configuration Instructions (Appendix B) at the end of this manual.

8. You can use MAX (which will install a shortcut on your desktop) to rename your preferred

method of connecting to your P.A. . .I. Quantum Gold control unit. o do so, make sure that

your Bluetooth module is plugged in to your computer and properly installed or make sure that

you have run the driver installer for the USB-to-serial cable and have plugged it into your

computer first. Make sure that you have one method of connection ready before starting MAX.

Once MAX is running, you can select the first link in the center window and then rename your

connection method to something more appropriate. For instance, rename COM1 to Bluetooth,

for example. hen, when you run the PQGold App you will see a more descriptive name rather

than the COM port.

Before installing the software on a new computer, you may wish to visit our website at

www.adhesiontesting.com to see if a newer version of the software is available.

Full upgrade installation instructions can be found there as well.

Congratulations!

You are now ready to take full advantage of the features of the

PQ old Software Suite.

For Technical Support, please call (301) 975-9798 from 9am to 5pm EST

or email [email protected].

6

PATTI® QUANTUM OLD OPERATION PROCEDURE

I. Pre-test Preparation

A. Pull-Stub Attachment

NOTE: A clean pull-stub and clean surface are required for good adhesion. If a pull-stub

fails to adhere to your coating it is usually due to poor surface preparation! Even new pull-

stubs are not considered “clean” because a residue is left on the pull-stub after

sandblasting. Any standard method for cleaning/degreasing aluminum can be used on the

pull stubs and mild solvents should be fine on your coating. he cleaned surface should not

be handled to prevent contamination from skin oils, etc. Do not reuse pull-stubs unless the

residual adhesive has been thoroughly removed and the cleaned surface restored.

Use cleaned pull-stubs within 24 hours for best results.

WARNIN : Always follow the epoxy/adhesive manufacturer's instructions. Use latex

gloves while mixing and applying adhesives to the test surface to avoid contact between

the adhesive and bare skin. A well-ventilated area is recommended when handling uncured

adhesives.

1. Prepare adhesive for application as recommended by the manufacturer.

2. If using adhesive masks (rather than cut-off rings), apply the mask to the location you

wish to test. Care should be taken not to touch the coating exposed in the center of the

mask (see note above).

3. Carefully apply enough adhesive to cover an area the size of a pull-stub on the coating

or test surface (in the center of the adhesive mask, if applicable). Also, apply a small

amount of adhesive to the flat, sandblasted surface of the stub head. Work the epoxy into

the roughened surface to fill the voids. Avoid depositing adhesive onto the stub threads.

4. Press the flat surface of the stub head against the epoxied area on the coating or test

surface. If using an adhesive mask, place the flat surface of the pull-stub onto the coating

in the center of the mask. Gently slide the stub around to ensure that it is in the center.

NOTE: Minimize any rotation, tilting, or sliding of pull-stub with respect to test coating

after contact is made, as this may introduce voids at the adhesive-test surface interface.

Although some movement is recommended when using the adhesive masks, try to disturb

the stub as little as possible once contact with the surface has been made.

7

8

PULL-STUB

SUBSTRATE

BACKIN PLATE (IF REQUIRED)

COATIN

FIGURE 2a

ADHESIVE

MASK

ADHESIVE

MASK

COATIN

SUBSTRATE

BACKIN PLATE (IF REQUIRED)

SUBSTRATE

EXCESS EPOXY

DISPLACED BY

ADHESIVE MASK

CROSS-SECTIONAL SCHEMATICS

OF PULL-STUB ADHERED TO COATIN

USIN ADHESIVE MASKS

FIGURE 2b

PULL-STUB

EXCESS EPOXY

DISPLACED BY

ADHESIVE MASK

PATTI® QUANTUM OLD OPERATION PROCEDURE (cont')

5. If you cannot use adhesive masks for some reason or simply prefer the older cut-off

rings, now is the time to utilize them. While holding the stub in place, press a cut-off

ring (knife edge towards test surface) around the stub and through the adhesive to the

coating or test surface.

NOTE: he use of either a cut-off ring or adhesive mask is very important. It displaces the

excess adhesive from the stub which reproduces the test area. his not only eliminates the

need for scoring or wiping, but ensures that the adhesive-test surface interface area is well-

defined. his allows for an accurate tensile strength conversion.

NOTE: A light clamping pressure (or weight) maintained on the stub during adhesive

curing will produce a stronger glue joint. his is optional.

6. Allow for the passage of a sufficient amount of adhesive cure time as specified by the

adhesive manufacturer.

NOTE: For most adhesives it is recommended that a cure time of at least 24 hours is

provided prior to pull testing. For a faster test, inquire about the P.I.P.S. (PA I Instant

Pull-Stubs) system. he PIPS system uses a light-cure adhesive and high-intensity

flashlight to allow for 5 minute tests! Ask your distributor.

9

10

PATTI® QUANTUM DIGITAL/GOLD CONNECTION ILLUSTRATION

TO WHITE SNAP-IN CONNECTOR

150 PSI IN MAX

TO GOLD THREADED CONNECTOR

AIR CYLINDER

REGULATOR

SOLD SEPARATELY;

CALL FOR DETAILS

AIR CYLINDER

OR SHOP AIR

(NOT REQUIRED IF

USING CO2 CARTIRDGES)

PISTON

FRONT PANEL

OF PATTI

REAR PANEL

OF PATTI

120 VAC

(NOT REQUIRED IF

USING 9V BATTERY)

TO BATTERY BOX

9V BATTERY

(NOT REQUIRED IF

USING 120 VAC POER)

GENUINE INNOVATIONS

16 g CO2 CARTRIDGE

PART #2062

(NOT REQUIRED IF

USING AIR CYLINDER

OR SHOP AIR)

GENUINE INNOVATIONS

CARTRIDGE HOLDER

11

Peak

Reset

PATTI

QUANTUM

GOLD

Supply

Pressure

Power

On/Off

Ad esion Tester

Piston Pressure

150 psi MAX In 12 VDC

Piston Out

9V

Serial Port

BATTERY

LIFT TO WITHDRAW

PSI

FRONT PANEL VIE

REAR PANEL VIE

PATTI® QUANTUM OLD CONTROL MODULE LAYOUT

12

Rate Run

CO2

ATTENTION: USE ONLY

GENUINE INNOVATIONS

16g CO2 CARTRIDGES!

GI PART #2062

Bluetoot

Serial

TOP-DO N VIE

PATTI® QUANTUM OLD CONTROL MODULE LAYOUT

PATTI® QUANTUM OLD OPERATION PROCEDURE (cont')

B. Instrument Preparation

1. Ensure that the unit has power by using one of the following two methods:

a. Place a 9V battery in the BATTERY slot on the rear panel of the unit.

Note that (1) new 9V battery shipped with your unit.

-OR-

b. Plug the included AC Adapter into a 120 VAC wall outlet. Plug the other end of

the adapter into the lower right hand-corner of the rear panel of the unit labeled

9 VDC.

2. urn on the PA I® QUANTUM GOLD by operating the Power On/Off rocker

switch on the left side of the front panel of the unit.

3. Pressurize the system using one of the following three methods:

CAUTION: Do not exceed 150 psi input pressure! Doing so may damage the gauges

and/or result in rupture of the internal hoses leading to expensive repairs!

a. High pressure bottled gas or any clean, constant inert gas supply

(i.e. Nitrogen [N2], Carbon Dioxide [CO2], filtered air, etc.)

i. Attach correct end of yellow hose to the threaded 150 psi MAX In air

connection on the lower left-hand side of the rear panel of the unit.

ii. Attach other end of yellow hose to gas supply regulator.

iii. Open gas high pressure valve and turn regulator valve handle clockwise

to produce a supply pressure between 100 psi (690 KPa) and 150

(1035 KPa) psi as read on the gauge. Remember, do not exceed 150 psi!

b. CO2 Cartridge

i. Place a CO2 cartridge into the black cartridge holder, spherical end first.

NOTE: It is impossible to pierce the CO2 cartridge if it is not inserted into

the cartridge holder in the correct orientation.

ii. hread the cartridge holder onto the gray threaded adapter labeled CO2

(located on the top of the unit) until the cartridge is pierced and gas flows

audibly into the Control Module.

NOTE: he PA I® QUANTUM is equipped with an internal regulator to

prevent overpressurization when charging the unit with a CO2 cartridge.

13

PATTI® QUANTUM OLD OPERATION PROCEDURE (cont')

c. PATTI® Air Pump

CAUTION: he PA I® QUANTUM must be configured correctly to be used in

conjunction with the PA I® Air Pump. If a PA I® Air Pump was not included in

your original package, please contact the manufacturer before attempting to use one

with your unit.

NOTE: Generally speaking, a supply pressure of at least 100 psi is needed for a

successful pull. However, you may find that this number is higher or lower depending

on your piston size. If you start a test and run out of supply air, you may obtain

inaccurate tensile strength measurements when continuing the same test with

replenished air.

i. Attach correct end of yellow hose to the threaded 150 psi MAX In air

connection on the lower left-hand side the rear panel of the unit.

ii. urn on PA I® Air Pump compressor.

iii. When Supply Pressure gauge on the right-hand side of the front panel

reads approximately 140 psi, turn off PA I® Air Pump compressor.

Remember, do not exceed 150 psi!

4. In the upper left-hand corner of the rear panel of the unit, identify the white Piston Out

connector. Push the metal spring fitting to the right until it clicks.

5. Snap the white connector of the blue hose into the Piston Out connection.

6. If using the included USB-->RS232 cable, connect the USB portion of the cable to an

available USB port on your computer. Your computer should automatically detect the

hardware. Connect the orange mini-adapter end of the cable to the back panel of the

control module via the Serial Port.

If using Bluetooth, no connections are needed at this time.

14

PATTI® QUANTUM OLD OPERATION PROCEDURE (cont')

II. Test Procedure

A. Control Module-Test Surface Interfacing

1. Remove clamp or weight from pull-stub (if applicable).

2. Carefully remove the cut-off ring from the pull-stub (if applicable).

wo possible methods for doing this are as follows:

NOTE: Remove the cut-off rings very carefully to disturb the pull-stub adhesive as little as

possible. his will produce the most accurate results.

his step can be skipped entirely if using our adhesive masks!

a. Using a utility knife, carefully cut down through the cut-off ring and to the coating

or test surface (preferred method).

b. Using a pair of slip-joint pliers, squeeze the sides of the ring and gently twist to

break the cut-off ring away from the adhesive.

3. Separate the piston body (“bottom” of piston) from the reaction plate (“top” of piston),

exposing the gasket. Ensure that the gasket is free of dirt and other debris.

4. Place the piston body over the pull-stub, with the felt side resting on the coating or test

surface and the gasket visible.

5. hread the Reaction Plate clockwise onto the pull-stub until light contact is made with the

piston body.

NOTE: Do not tightly thread the Reaction Plate to the pull-stub. Doing so may weaken the

adhesive bond between the pull-stub and the test surface and may even break the pull-stub

from the surface!

6. Reverse thread the Reaction Plate counter-clockwise about one-quarter (¼) turn to allow

gasket sealing and alignment of Reaction Plate perpendicular to axis of pull-stub.

7. Connect the blue hoses by threading the connector on the end of the blue hose from the

piston to the threads on the end of the blue hose to the Control Module.

15

PATTI® QUANTUM OLD OPERATION PROCEDURE (cont')

B. Control Module Operation

WARNIN : It is recommended that safety goggles be worn during each and every test. Use

extreme caution during testing. Piston recoil will occur upon pull-stub-sample separation.

Stand clear of the piston after it has been attached to the pull-stub and before conducting your

pull test.

1. urn on the PA I® QUANTUM GOLD by operating the Power On/Off rocker switch

on the left side of the front panel of the control module.

2. Ensure that the Piston Pressure display in the center of the front panel of the unit reads

zero (0) psi (+/- 1 psi). If not, open the Rate valve by turning the Rate Valve Knob on the

left-hand side of the top of the unit counter-clockwise about a half turn. hen push the

Peak Reset button on the right-hand side of the front panel.

3. If Step 2 above does not bring the display to zero, identify the lone screw on the bottom on

the unit. hread the screw into the control module until the display zeroes, then back the

screw off again.

4. Close the Rate Valve by turning the Rate Valve Knob clockwise until finger tight.

CAUTION: he closed position of the Rate valve knob is finger tight. It is not intended for

shut-off service! Repeated over-rotation (clockwise) of this knob will cause permanent

damage to the valve seat and is not covered by the warranty.

DAMA E TO RATE VALVE WILL REQUIRE FACTORY SERVICIN

AT OWNER'S EXPENSE.

5. If using conversion charts rather than the bundled software suite, skip to Step 5 on page

13.

If using the PA I® QUANTUM GOLD Software application, follow steps a-f on the

following two pages (17 & 18).

16

This manual suits for next models

1

Table of contents