AU Tool CT400 User manual

www.autooltech.com

AUTOOL CT400

Injector Cleaner & Tester

User Manual

Copyright Information

All rights reserved by AUTOOL TECH. CO., LTD. No part of this publication may

be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise, without

the prior written permission of AUTOOL. The information contained herein is

designed only for the use of this unit. AUTOOL is not responsible for any use of

this information as applied to other units.

Neither AUTOOL nor its affiliates shall be liable to the purchaser of this unit or

third parties for damages, losses, costs, or expenses incurred by purchaser or

third parties as a result of: accident, misuse, or abuse of this unit, or unautho-

rized modifications, repairs, or alterations to this unit, or failure to strictly

comply with AUTOOL operating and maintenance instructions.

AUTOOL shall not be liable for any damages or problems arising from the use of

anyoptions or any consumable products other than those designated as

OriginalAUTOOL Products or AUTOOL Approved Products by AUTOOL.

Other product names used herein are for identification purposes only and may

betrademarks of their respective owners. AUTOOL disclaims any and all rights

in those marks.

Manual are either trademarks, registered trademarks, service marks, domain

names, logos, company names of or are otherwise the property of AUTOOL or

its affiliates. Incountries where any of the AUTOOL trademarks, service marks,

domain names, logos and company names are not registered, AUTOOL claims

other rights associated with unregistered trademarks, service marks, domain

names, logos, and company names. Other products or company names referred

to in this manual maybe trademarks of their respective owners. You may not use

any trademark, service mark, domain name, logo, or company name of

AUTOOL or any third party without permission from the owner of the applicable

trademark, service mark, domain name, logo, or company name. You may

contact AUTOOL by visiting AUTOOL at https://www.autooltech.com, or writing

to [email protected], to requestwritten permission to use Materials on

this manual for purposes or for all other questions relating to this manual.

Table of Contents

Overview

1.1 Functions and features

1.2 Working environment and technical parameters

Structure

2.1 Overview structure

2.2 Control panel

Operation Procedures

3.1 Ultrasonic cleaning

3.2 Test functions

Maintenance

Precautions

Warranty

1

1

2

3

3

3

4

4

5

8

9

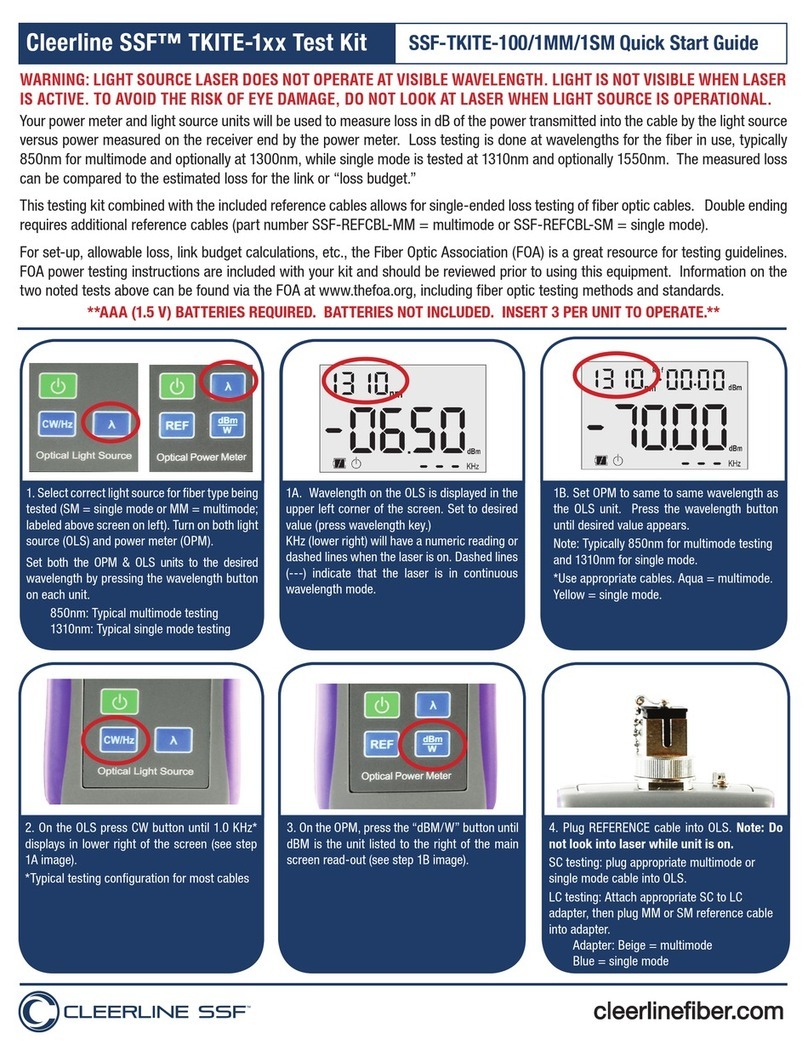

Overview

1.1 Functions and features

This GDI Fuel Injector 6-cylinder Cleaner and Tester is a great upgrade, which

adapts the latest GDI design. It not only can be used to clean and test the

standard injectors, of note that it can carry out GDI injectors cleaning and tesst.

It comes with multi voltages available for GDI injectors, which enables to adapt

for different types of injector testing. The machine is the necessary and preferred

equipment for the automotive serving and maintenance, research, and teaching

training departments.

Functions

● Ultrasonic cleaning: To perform simultaneous cleaning on one or several

injectors and to remove the carbon deposits on the injector completely.

● Uniformity test: To test the uniformity of injecting amount of each injector.

● Sprayability test: To monitor the spraying status of each injector with the

help of a backlight.

● Leakage test: To test the sealing and dribbling conditions of injectors under

system pressure.

● Injecting flow test: To check the injecting amount of the injector under

specific working parameters (e.g. same time, same number of times).

● Automatic test: Under specific working parameters, test injectors by

simulating different working conditions.

● Adopted with the latest unique GDI fuel injector driving software, which can

drive 12V, 70V, 120V high-pressure fuel injectors.

Features

● Adopting the powerful ultrasonic cleaning technology, the equipment offers

complete cleaning to the injectors.

● Fuel pressure control through microcomputer offers stable pressure control

and large adjustable range.

● Adopting high-definition digital control panel display, it makes the operation

simple and easy to learn.

● Test liquid level can be displayed visually. It can also be recovered for

recycling use.

● With the help of the bright background light of the LED, it is possible to

clearly observe the various working conditions of the injectors.

● Replaceable composite coupling with patented and suitable for many

models.

● The test time, operating frequency, number of injecting, and minimum

switching pulse width of the injector can be adjusted freely within the allowed

adjustment range.

1

1.2 Working environment and technical parameters

Working environment

● Power supply: AC 110/220V ±10%

● Frequency: 50-60HZ±0.5

● Relative humidity: <85%

● Ambient temperature: 0℃~+40℃

● External magnetic field strength: <400A/m

● No open flames are allowed around

Technical parameter

● Fuel tank capacity: 1500 ml

● Test tube amount: 140 ml

● RPM range: 0~7500 r/min

● Time range: 0~9900 times

● PWM pulse width: 0~20.0 ms

● System pressure: 0~0.55Mpa (adjustable)

● Timing: 0~20 minutes adjustable

● Ultrasonic cleaning power: 60W (intermittent work)

● Ultrasonic cleaning frequency: 28 KHZ±0.5 KHZ

● Dimensions: 390mm (length) × 410mm (width) × 430 mm (height)

● Weight: 16.6KG

2

Structure

2.1 Overview structure

1- Filling inlet; 2- Test tube; 3- Drain button; 4- Control panel;

5- Pulse signal cable; 6- Ultrasonic cleaning bath; 7- Power switch;

8- Power socket; 9- Pressure gauge; 10- Test liquid drain valve;

2.2 Control panel

● Pulse width display: function options and pulse width adjustment.

● Display of working hours/injecting times: display the working hours and

injecting times of the injectors.

● Start key: press to execute the selected work item.

● Function menu selection buttons.

● Pause key: Press it to temporarily stop the selected work item.

● Time and frequency adjustment button: adjust the working time and spray

frequency of the fuel injector.

● Stop key: stop the selected work item and return to the selected work item.

● Pressure decrease adjustment button.

3

● Pressure increase adjustment button.

● Text description of function menu.

How to use the drain button

When performing work items 8, 9, and 10, press the button to close the drain

valve. Then the oil injected by the fuel injectors is closed in the glass tube, so as

to compare the amount of oil injected by each fuel injector. After the observation,

open the oil drain valve and return the test liquid to the oil tank.

Operation Procedures

3.1 Ultrasonic cleaning

Injector Cleaner takes advantage of the penetrability and cavitation impact

wave caused by ultrasonic waves traveling through the middle to provide

powerful cleaning on objects with complex shapes, cavities, and pores so that the

stubborn carbon deposits can be removed from the injectors.

Preparation:

● Remove the injector from the vehicle engine to check the rubber seals inside

for damage. Replace the damaged rubber seals with another same type of

rubber seal to avoid leakage during testing. Put the outside of injectors in

gasoline or detergent, and wipe them with a soft cloth after cleaning the outside

oil sludge carefully.

● Turn on the power (Note: There will be a delay of several seconds when this

device is restarted after a long power disconnection).

● Take out the cleaning bracket from the accessory box, then put it into the

ultrasonic bath, and put the clean fuel injector in the positioning hole of the

cleaning bracket in the ultrasonic bath.

3.1.2 Operation steps

Ultrasonic Cleaning:

● Add appropriate injector cleaning liquid into the ultrasonic bath, which

slightly immerses over the cleaning bracket will be fine.

● Turn on the ultrasonic switch on the right side of the main unit to start

ultrasonic cleaning.

● During the ultrasonic cleaning process, pulse signals can be input to the fuel

injector.

Steps:

● Plug the injector pulse signal wires into injectors respectively in turn. (Special

injectors need to be connected with adapter wires).

● Press the item selection up and down keys to select the "01 Ultrasonic

Cleaning" item, and then press the working time up and down keys to set the

4

time. (The system defaults to 10 minutes, if you need to modify the time, you can

change it with the up and down keys)

● Press the run key, and the system starts to input pulse signals.

When finished cleaning, take out the injectors from the ultrasonic tank. Wipe off

the cleaning liquid with a soft cloth and prepare for the next operation.

Notes:

● During the cleaning process, you can hear the intermittent vibration when

you take the fuel injector out and put it near your ear, which can determine

whether the injector has a pulse signal.

● Before the injector detergent is added into the ultrasonic cleaner, do not turn

on the ultrasonic cleaner. Otherwise, damage may be incurred.

● Only the ultrasonic cleaning liquid matched with the machine can be added

to the ultrasonic tank, and other cleaning liquid can not be used instead,

otherwise, the surface coating of the equipment and the mask will peel off, which

will not be covered by the warranty.

3.2 Test functions

This function is to detect the sprayability, dripping, blockage, fuel injecting

angle of the fuel injectors and the amount and uniformity of the fuel injection of

each fuel injector at different RPM.

3.2.1 Preparation

● Add test liquid. Pour the test liquid from the filling port. (Approximately

1000ML is added, and the liquid level should not be lower than 800ML every

time)

● Installation of fuel injectors

Schematic diagram of injector installation

A. Install the injector adapter and the plug into the Fuel distributor assembly

B. Install the fuel injector in the forward direction (apply a little grease on the "O"

ring of the fuel injector)

5

Adapter for fuel

injector

Injector

Fuel distributor

assembly

C. Install the fuel distributor assembly and the fuel injectors on the Top assem-

bly plate and tighten and fix it with a fixed screw nut and a fixed screw sleeve.

Get ready to test.

D. Select 12v/70v/120v according to injector type.

3.2.2 Steps:

Item 02 idle speed test:

● Connect the quick connector of the black outlet hose on the machine with

the male end connector on the fuel distributor assembly, and insert the pulse

line of the fuel injector.

● Press the item selection up and down keys to select the "02 Idle Speed

Test" item.

● Press the working time up and down keys to set the time. (Normally set to

10 minutes)

● Press the “run” key to start working.

● Rotate the pressure adjustment knob to adjust the pressure to 2-5 kg.(In the

electronic spraying system, the oil pressure is generally 2-5 kg).

● Press the up and down keys to select the appropriate pulse width. (The

system defaults to 3MS, generally adjusted to 3MS).

● The working time will gradually decrease, and when it reaches 0, the

system will stop automatically.

03 middle-speed test:

● Press the item selection up and down keys to select the "03 middle-speed

test" item.

● Press the RUN button.

● The rest of the operation steps are consistent with item 02.

04 High-speed tests:

● Press the item selection up and down keys to select the "04 High-speed

test" item.

● Press the RUN button.

● The rest of the operation steps are consistent with item 02

05 Accelerated test:

● Press the project selection up and down keys to select the "05 Accelerated

test" item.

● Press the RUN button.

Notes:

1)The fuel pressure, working time and pulse width are automatically set by the

system. The time system presets 10s as a loop cycle, which can be set by the

user.

6

7

2)The system will automatically loop three times in a row to simulate the working

conditions and fuel spraying amount of the fuel injectors when the engine is

accelerating uniformly at 1,500 -15,000 rpm.

06 Various speed test:

● Press the item selection up and down keys to select the "06 Various speed

est" item.

● Press the RUN button.

Notes:

1)The fuel pressure, working time and pulse width are automatically set by the

system. The time system presets 10s as a loop cycle, which can spare the labor

of setting by the user.

2)The system will automatically loop three times in a row to simulate the working

conditions and fuel spraying amount of the fuel injectors when the engine is

idling (1,500 rpm), middle-speed (9,000 rpm), and high-speed (15,000 rpm).

07 Leakage test:

● Press the item selection up and down keys to select the "07 Leakage test"

item.

● Press the working time selection keys to set the time. (Generally set to 1

minute)

● The remaining operation steps are consistent with item 02.

Notes:

1)The pulse width system is preset to 3ms, no need to set it again.

2)Simulate whether the fuel injectors drip and leak when the oil pressure of the

vehicle is 0.3Mpa.

tem 08 Idle fuel injecting amount test:

● Press the item selection up and down keys to select the "08 Idle fuel

injecting amount test" item.

● Press the up and down keys to set the number of times of injection.

(Generally set to 2,000 times)

● The remaining operation steps are consistent with item 02.

Notes:

1)Simulates the working condition and injection amount of the engine at idle

speed when the injectors work a certain number of times.

09 Middle-speed fuel injecting amount test:

● Press the item selection up and down keys to select the item "09

Middle-speed fuel injecting amount test".

● The rest of the operation steps are consistent with item 08.

10 High-speed fuel injecting amount test:

8

● Press the item selection up and down keys to select the "10 High-speed fuel

injecting amount test" item.

● The rest of the operation steps are consistent with item 08.

Notes:

1)Uniformity. This is for checking the uniformity carried out at various rpm.

When the test liquid level is at 2/3 of the test tube, please pause or stop the

machine to observe the uniformity of the injecting amount. Injecting difference of

all injectors on one vehicle should be kept within 2%. Or refer to the relevant

technical manual of the fuel injector to determine the uniformity of the injecting

amount.

2)Observe the shape of the injectors. Observe whether the injecting shapes and

angles of all fuel injectors on the same vehicle are identical at various speeds.

At the same time, you can adjust the injection pulse width of the fuel injectors to

compare whether the minimum injection pulse width among the fuel injectors is

consistent.

3) Leakage test. Leakage test is to inspect the sealing conditions of the injector

needle valve under system pressure. (Observe the tightness of the fuel injectors,

generally, there should be no leakage within one minute)

11 Reverse Flush Test:

● Press the item selection up and down keys to select "11 Reverse Flush",

and install the injectors in the opposite direction for cleaning.

12 Fully Automatic Cleaning items:

● Cleaning time can be set to a maximum of 20 minutes. Please connect to

various special parts that can clean the combustion chamber or throttle.

Maintenance

1. Tidy up

● Turn off the power and unplug the power plug.

● Put all the connectors back into the accessory box for storage.

● Put the ultrasonic cleaner back into the original bottle and seal it, and wipe

the equipment clean with a dry soft cloth.

● If it is not used for a long time, open the test liquid valve and drain the test

liquid back into the original bottle for sealed preservation.

2. Maintenance

Replacement of test liquid

● Impurities can be built up in the test liquid after being used for a period of

time. Do not use contaminated test liquid, otherwise, injector and fuel pumps

9

can be blocked. Drain the test liquid by removing the level indicator on the left of

the main unit. It is better to clean the fuel tank with a little test liquid before the

tank is filled in with the new liquid. After cleaning, close the test liquid valve

again and pour in new test liquid.

Replacement of Fuse

● There is a square box marked with a fuse at the power socket on the left

side of the equipment, and the fuse can be seen by opening the square box. If it

is blown, replace it with a new one (5A).

Precautions

● Since the test device is quartz glass, which is easy to be broken, please

don't place other objects around the device to avoid breaking by bumping.

● If there is no digital display after power on (there may be a delay of several

seconds), please check whether the power supply has electricity; if there is a

power failure, please check whether the plug is firmly connected, or check

whether the fuse is blown. If there is no break, and the switch is still not working

after pressing several times, please contact your local dealer, do not disassem-

ble it by yourself, otherwise our company shall not warranty.

● Do not switch on the ultrasonic system when there is no ultrasonic

detergent in the ultrasonic cleaning chamber. Otherwise, damage to the

ultrasonic cleaner can result.

● It must be emptied completely before adding 1000ml of test liquid for every

test liquid change.

● The use of unqualified test liquid will cause corrosion of the pump and oil

supply line and failure of the pressure gauge.

● Only the ultrasonic cleaning liquid matched with the machine can be added

to the ultrasonic bath, and other cleaning liquid can not be used instead,

otherwise, the surface coating of the equipment and the mask will peel off, which

will not be covered by the warranty.

● Kerosene, gasoline, pure water and other testing and cleaning solutions are

strictly forbidden to be used as the testing and cleaning solution for this equip-

ment. Otherwise, it will damage the "O" ring and rubber parts of the pipeline

inside the equipment and cause leakage.

● Do not mix cleaning liquid with testing liquid.

● Please place the machine on a flat surface and use the four feet to support

the weight of the machine, otherwise the ultrasonic cleaning bath will be

damaged, which is not covered by the warranty.

Warranty

● Thank you for choosing our products, we will provide you with the following

services and promises.

● The warranty period of this product is 1 year.

● After the warranty period expires, repairs will be charged for replacement

parts.

● After the failure, please contact the manufacturer, we will give you the most

complete service in the

shortest time.

The following items are not covered by the warranty:

● Vulnerable parts are not covered by the warranty, including: glass tube, signal

sire, stickers, connectors pressure gauge, oil outlet pipe.

● When no cleaning agent is added to the ultrasonic tank, turning on the

ultrasonic

cleaning switch will damage the ultrasonic system, which is not covered by the

warranty.

● If the testing agent is not replaced in time after long-term use, the oil pump

filter

screen is blocked and the oil pump is burned out of the warranty.

● The use of fuel injector cleaning agent as fuel injector testing agent will cause

the

fuel pump to burn out, which is not covered by the warranty.

● Man-made faults are not covered by the warranty.

Disclaimer: All information, illustrations, and specifications contained in this

manual, AUTOOL resumes the right of modify this manual and the machine itself

with no prior notice. The physical appearance and color may differ from what is

shown in the manual, please refer to the actual product. Every effort has

been made to make all descriptions in the book accurate, but inevitably there

are still inaccuracies, if in doubt, please contact your dealer or AUTOOL

after-service centre, we are not responsible for any consequences arising from

misunderstandings.

深圳市偶然科技有限公司

广东省深圳市宝安区北八路航城锦驰产业园

Shenhua Innovation Park, Baoan, Shenzhen, China

www.autooltech.com

+86-400 032 0988 / +86-755-27807580

Table of contents

Other AU Tool Test Equipment manuals

AU Tool

AU Tool CT180 User manual

AU Tool

AU Tool BT 260 User manual

AU Tool

AU Tool BST-100 User manual

AU Tool

AU Tool CT500 User manual

AU Tool

AU Tool LM708 User manual

AU Tool

AU Tool BST-100 User manual

AU Tool

AU Tool BT-660 User manual

AU Tool

AU Tool SPT360 User manual

AU Tool

AU Tool BT160 User manual

AU Tool

AU Tool BT70 User manual