Contents

1Introduction ........................................................................................................................................... 5

General ................................................................................................................................................... 5

Validity .................................................................................................................................................... 5

Target groups.......................................................................................................................................... 5

Qualification of target group.................................................................................................................... 5

1.3.1.1 Users....................................................................................................................................................... 5

1.3.1.2 Qualified personnel ................................................................................................................................. 5

Conformity............................................................................................................................................... 5

2Proper use ............................................................................................................................................. 6

Operation of the unit................................................................................................................................ 6

Intended use ........................................................................................................................................... 6

Provisions for operation with fireplaces................................................................................................... 6

Guarantee conditions, warranty and liability............................................................................................ 6

Guarantee conditions.............................................................................................................................. 6

Warranty ................................................................................................................................................. 6

Liability.................................................................................................................................................... 7

3Safety ..................................................................................................................................................... 7

Symbols used ......................................................................................................................................... 7

Safety regulations ................................................................................................................................... 7

3.1.2.1 Safety instructions – general................................................................................................................... 7

3.1.2.2 Safety instructions – Installation.............................................................................................................. 8

Installation conditions.............................................................................................................................. 8

4Chapter for operators and qualified personnel .................................................................................. 8

Product description ................................................................................................................................. 8

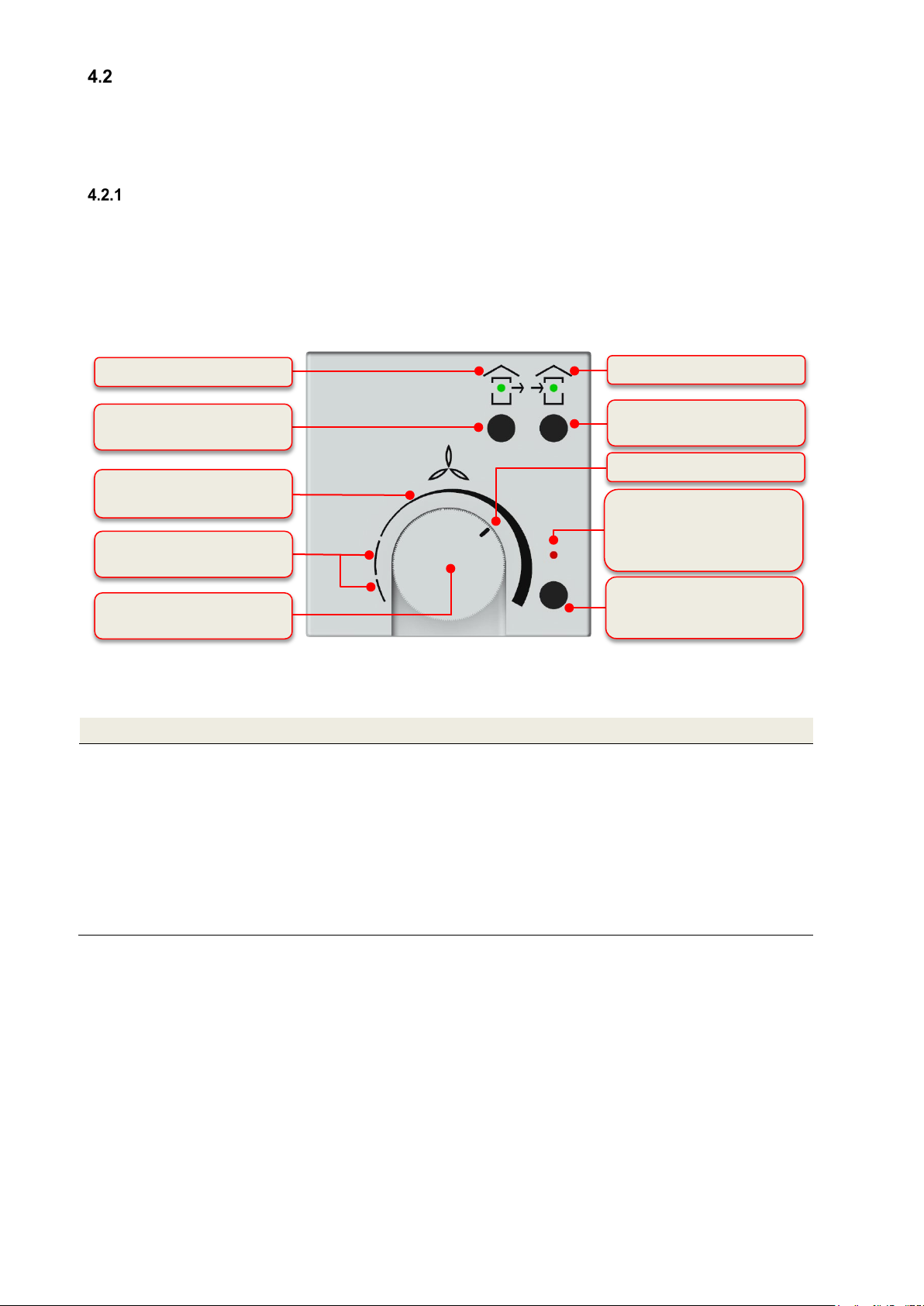

Control panel........................................................................................................................................... 9

Main components.................................................................................................................................... 9

Type label ............................................................................................................................................... 9

Frost protection ....................................................................................................................................... 9

Available control modules ..................................................................................................................... 10

External control panel ........................................................................................................................... 10

4.2.1.1 Control panel operating functions ......................................................................................................... 10

4.2.1.2 Signals used to indicate working/maintenance conditions .................................................................... 11

External control signal 0–10 V .............................................................................................................. 11

Boost ventilation mode with external boost ventilation key ................................................................... 12

Maintenance by the user....................................................................................................................... 12

Replacing the unit filters........................................................................................................................ 12

Resetting the filter running time ............................................................................................................ 15

What should I do in case of a fault?...................................................................................................... 15

Disposal ................................................................................................................................................ 15

5Chapter for qualified persons ............................................................................................................ 15

Installation requirements....................................................................................................................... 15

Transport and packaging ...................................................................................................................... 15

Checking the scope of delivery ............................................................................................................. 15

Mounting ............................................................................................................................................... 16

Wall mounting ....................................................................................................................................... 16

Fitting on Floor stand (optional) ............................................................................................................ 17

Connecting the ventilation tubes........................................................................................................... 19

Connecting the condensate drain hose................................................................................................. 20

Electrical connections ........................................................................................................................... 21

Connecting the control panel ................................................................................................................ 22

5.3.1.1 Connecting the connecting cable to the flat connector plug.................................................................. 22

5.3.1.2 Connecting the connecting cable to the control panel........................................................................... 22

Connecting external boost ventilation keys........................................................................................... 23

Connecting external sensors................................................................................................................. 23

Connecting an external pre-heater........................................................................................................ 23

Commissioning ..................................................................................................................................... 24

Readiness for operation........................................................................................................................ 24

Adjusting the air volume flow ................................................................................................................ 24

Adjusting the valves .............................................................................................................................. 24

Service and maintenance...................................................................................................................... 25

Inspection and cleaning of the heat exchanger..................................................................................... 25