1General Information

2 9964042xx1-mub-en - V02 2021/11

Contents

1General Information.........................................................................................................3

1.1 Scope of these instructions ..........................................................................................3

1.2 About this product ........................................................................................................3

1.3 Designated use ............................................................................................................3

2Safety instructions ...........................................................................................................4

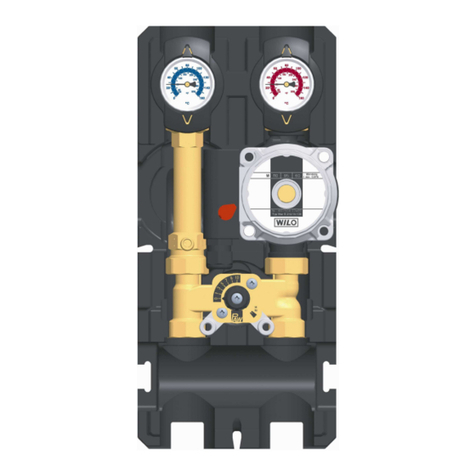

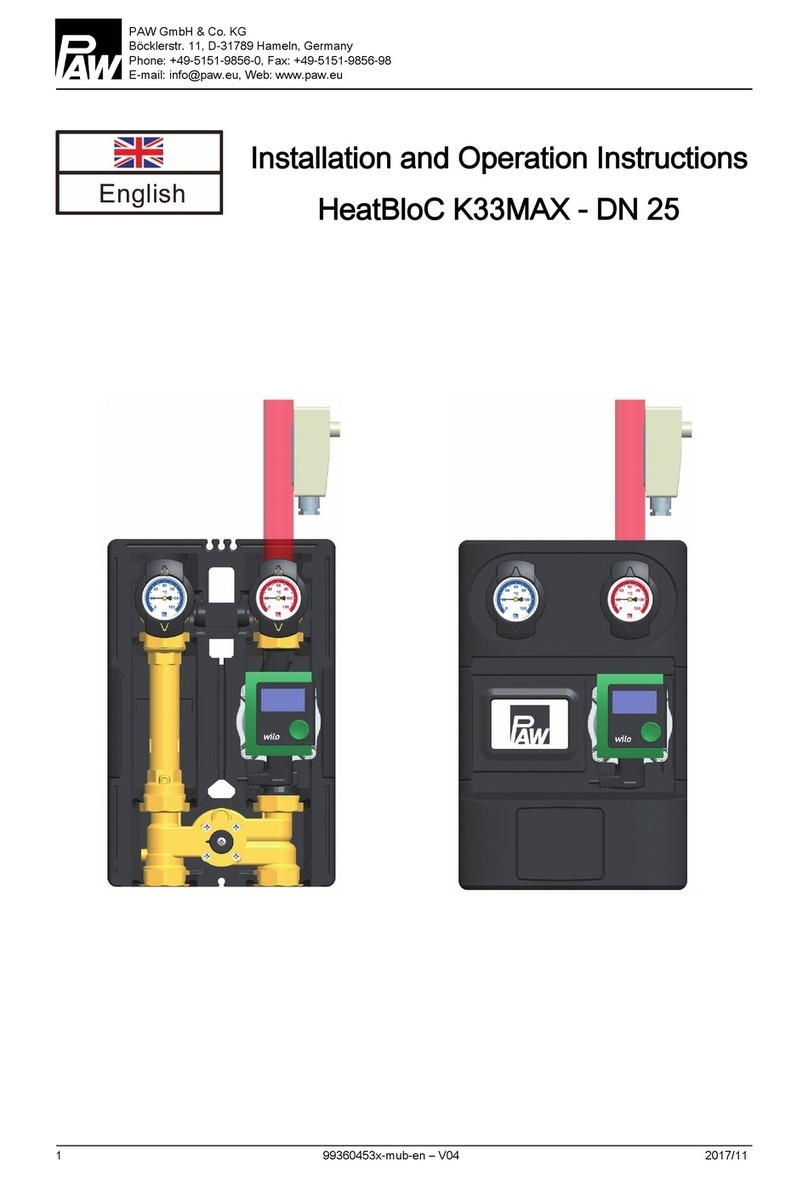

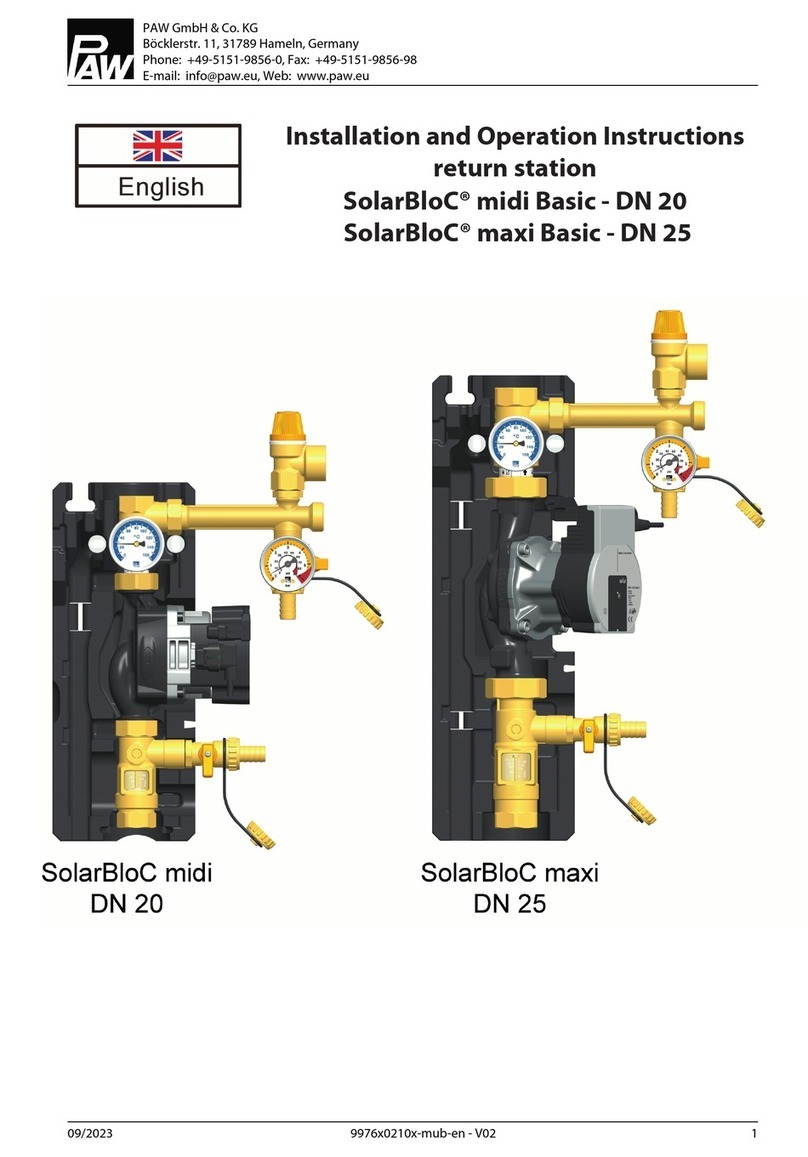

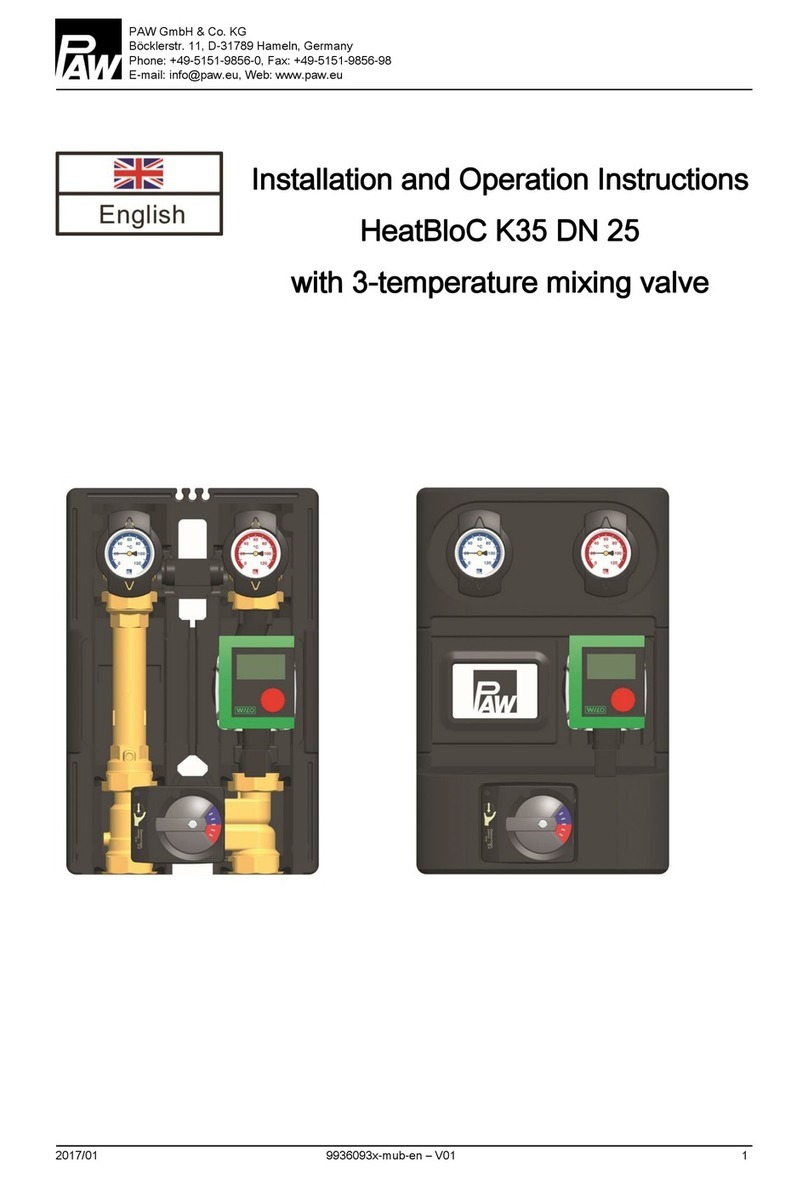

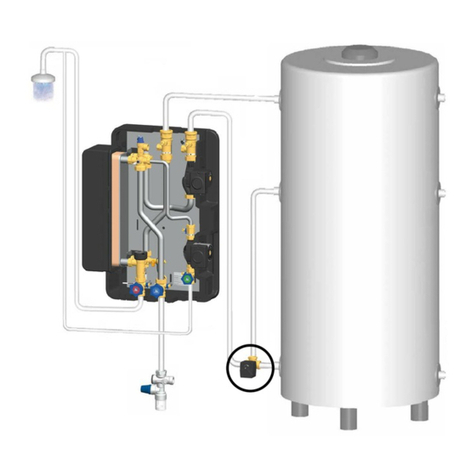

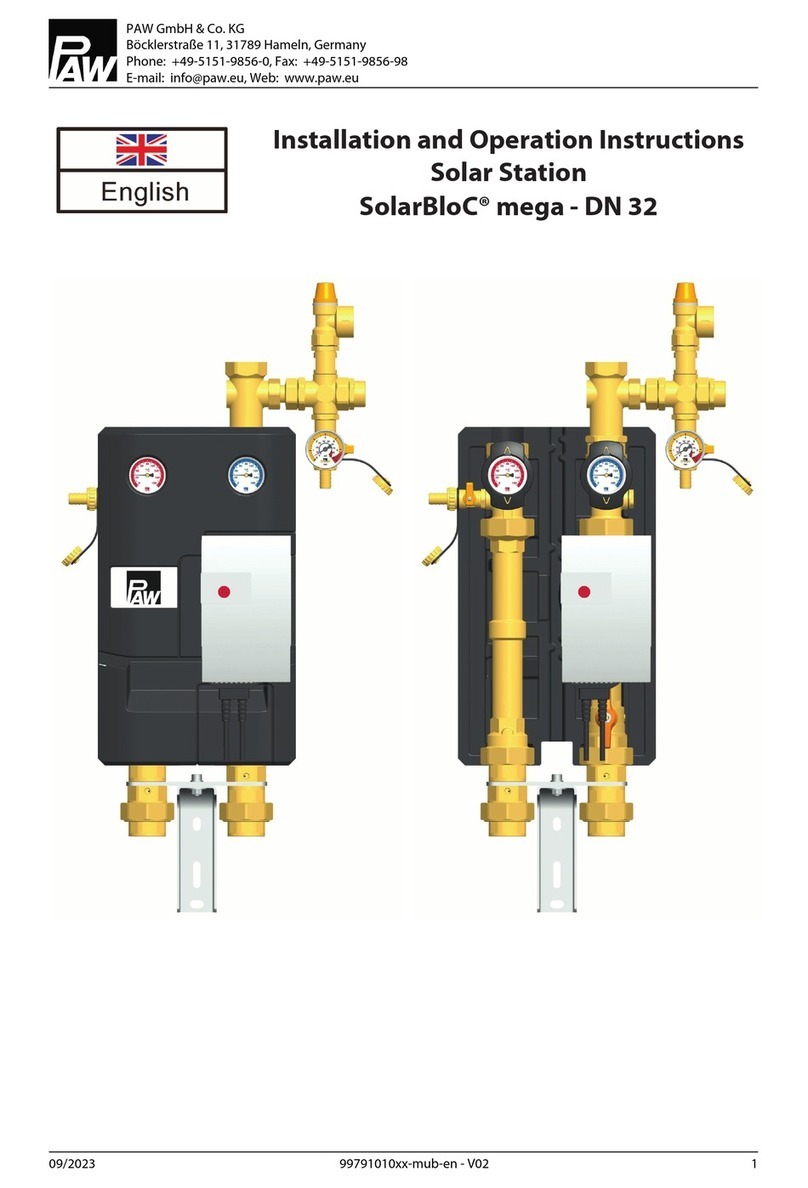

3Product description..........................................................................................................5

3.1 Assembly and installation [specialist] ...........................................................................5

3.2 Controller connection FC3.10.......................................................................................7

3.3 Controller connection FC4.13..................................................................................... 11

4Scope of delivery...........................................................................................................14

4.1 Switch valve set FriwaMidi (64042631 + 64042641)................................................... 15

4.2 Switch valve set FriwaMaxi (64042731 + 64042741).................................................. 16

5Technical data 2-way zone valve....................................................................................17

6Disposal........................................................................................................................18

7Commissioning report....................................................................................................19

Item no. 9964042xx1-mub-en - Version V02 – Date 2021/11

Translation of the original instructions

We reserve the right to make technical changes without notice!

Printed in Germany – Copyright by PAW GmbH & Co. KG

PAW GmbH & Co. KG

Böcklerstraße 11

31789 Hameln, Germany