1 For your safety

2 99473903xNA – V02 2011/11

Contents

1For your safety .................................................................................................................................................. 3

1.1About this manual ............................................................................................................................................... 3

1.2Designated use ................................................................................................................................................... 3

1.3Qualification of the installer ................................................................................................................................. 4

1.4Hand-over of the system [Specialist] ................................................................................................................... 4

1.5General safety instructions .................................................................................................................................. 5

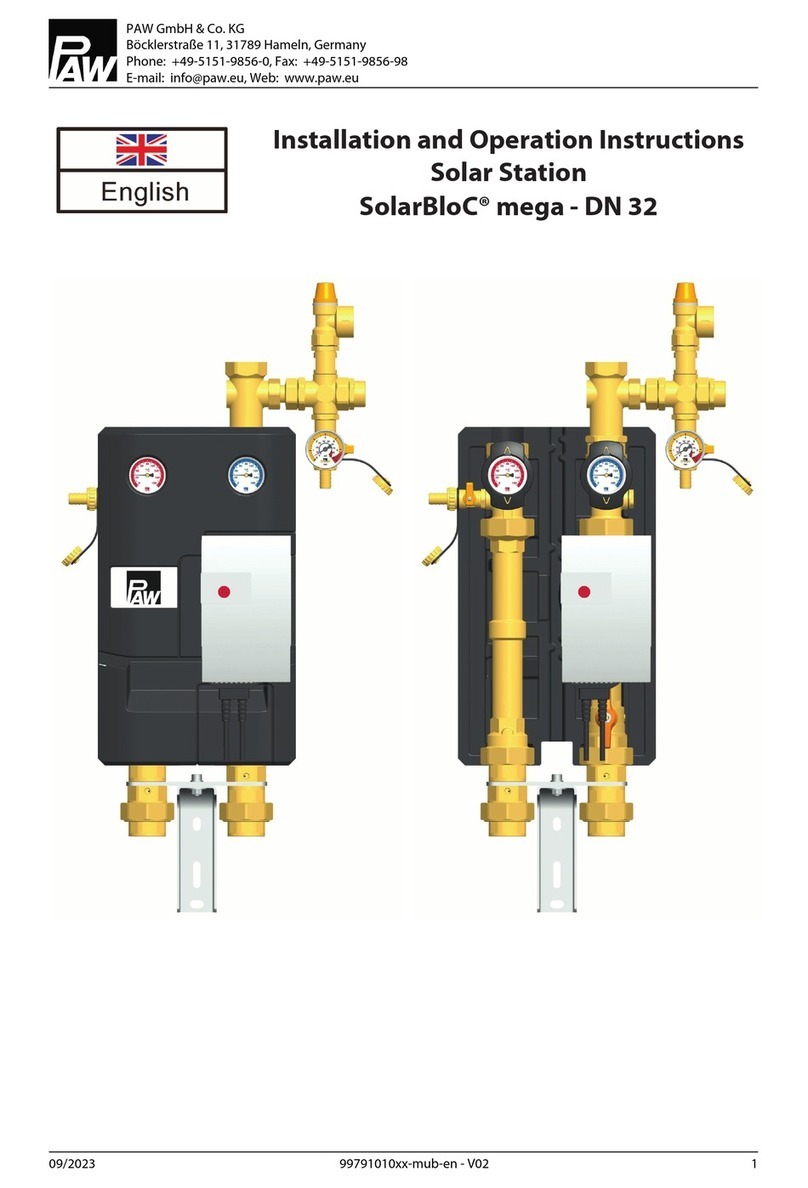

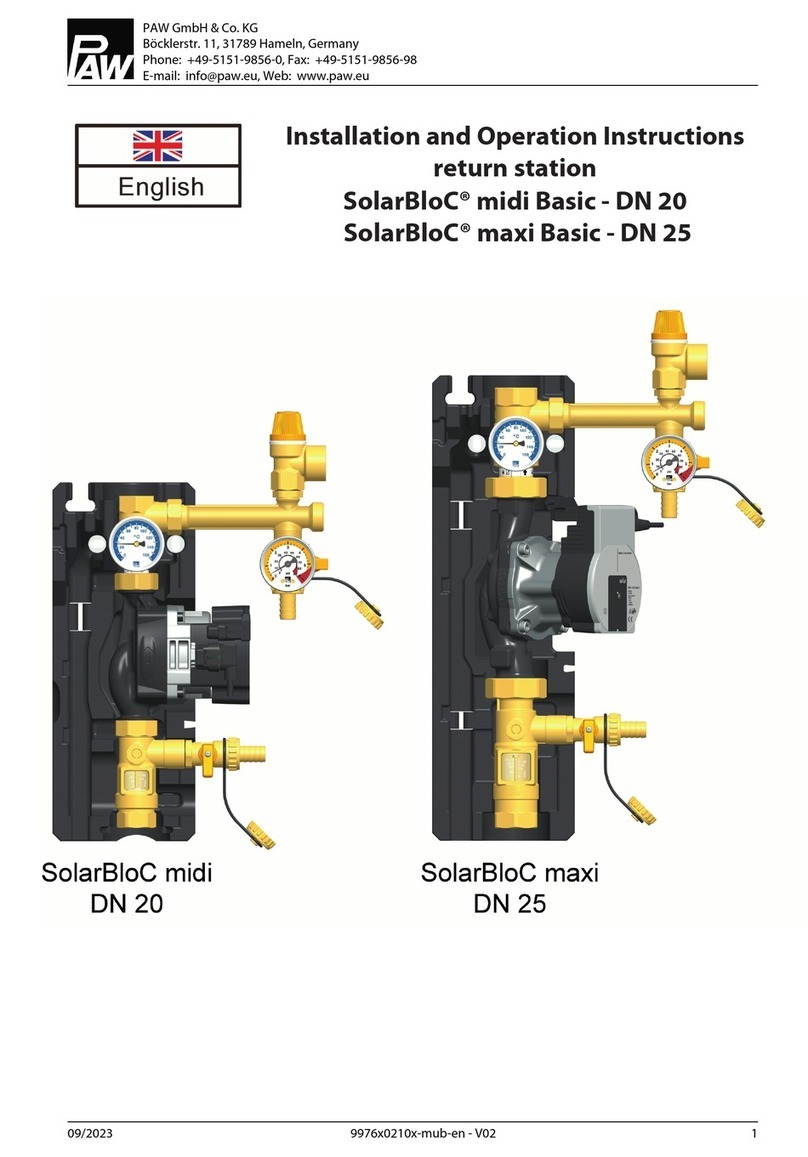

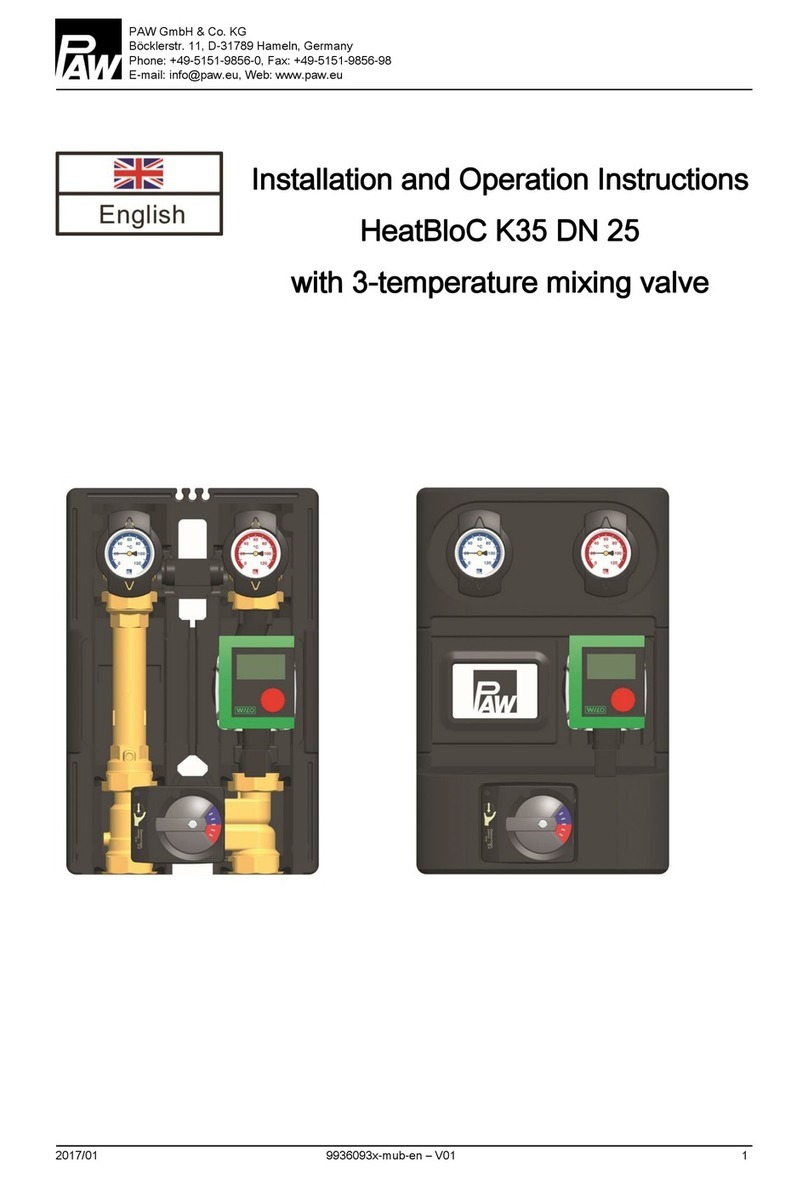

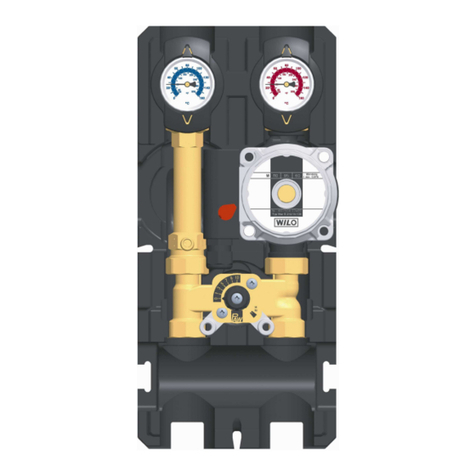

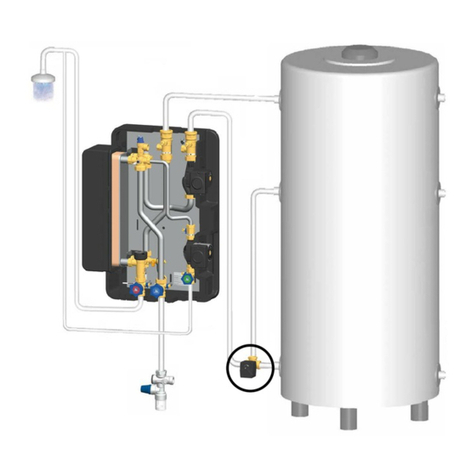

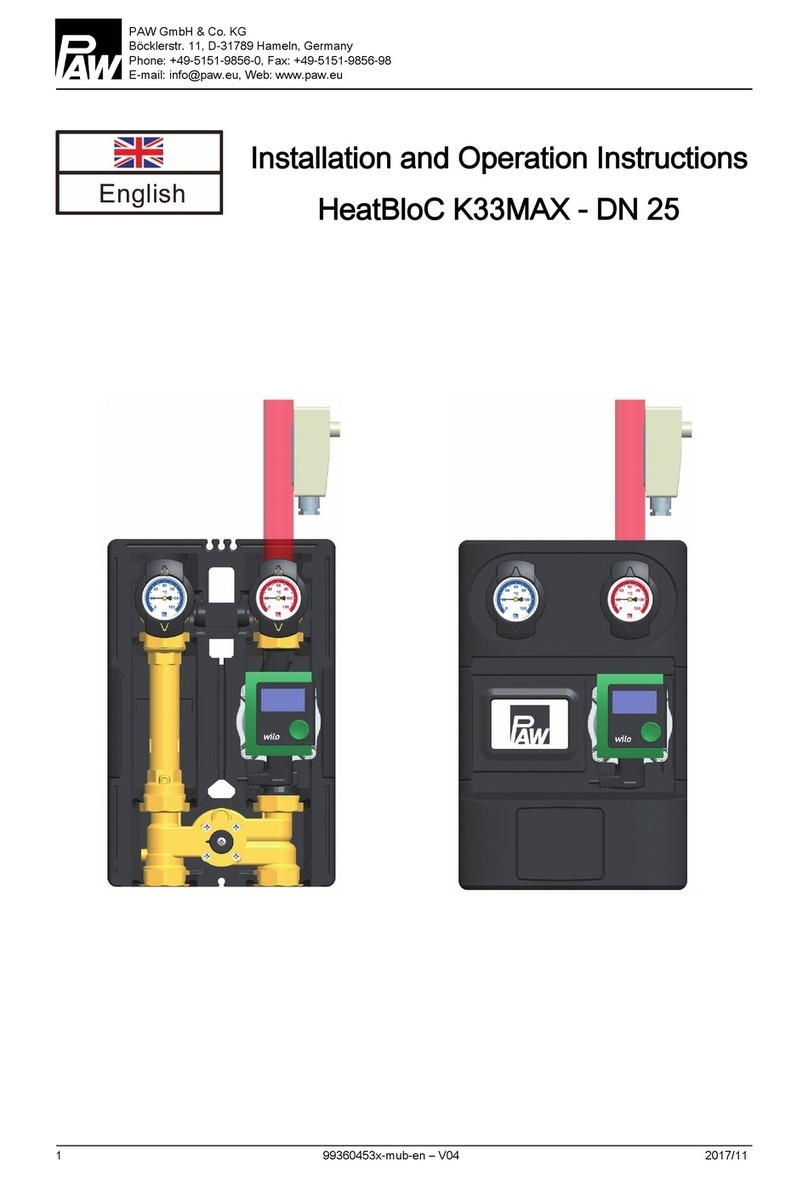

2Product description ............................................................................................................................................ 6

2.1Function [Specialist] ............................................................................................................................................ 7

2.2Thermal control valve [Specialist]........................................................................................................................ 9

2.3Overflow valve [Specialist] ................................................................................................................................ 10

2.4Check valve [Specialist] .................................................................................................................................... 11

3Mounting and installation [Specialist] ............................................................................................................... 12

3.1Installation directly to the wall on a wall bracket [Specialist] ............................................................................. 13

3.2Installation under a distribution manifold [Specialist] ......................................................................................... 13

3.3Piping and start-up [Specialist] .......................................................................................................................... 13

4Cleaning .......................................................................................................................................................... 14

5Maintenance and decommissioning [Specialist] ............................................................................................... 14

6Spare parts ..................................................................................................................................................... 15

7Technical data and pressure drop characteristics ............................................................................................ 16

7.1Pressure drop characteristic ............................................................................................................................. 17

Item no. 99473903xNA – Version V02 – Issued 2011/11

We reserve the right to make technical changes without notice!

Printed in Germany – Copyright by PAW NA Limited Partnership

PAW NA Limited Partnership

45 Davis Street

Webster, Ma 01570, USA