Table of Contents

1 General Information...................................................................................................3

1.1 About these instructions............................................................................................3

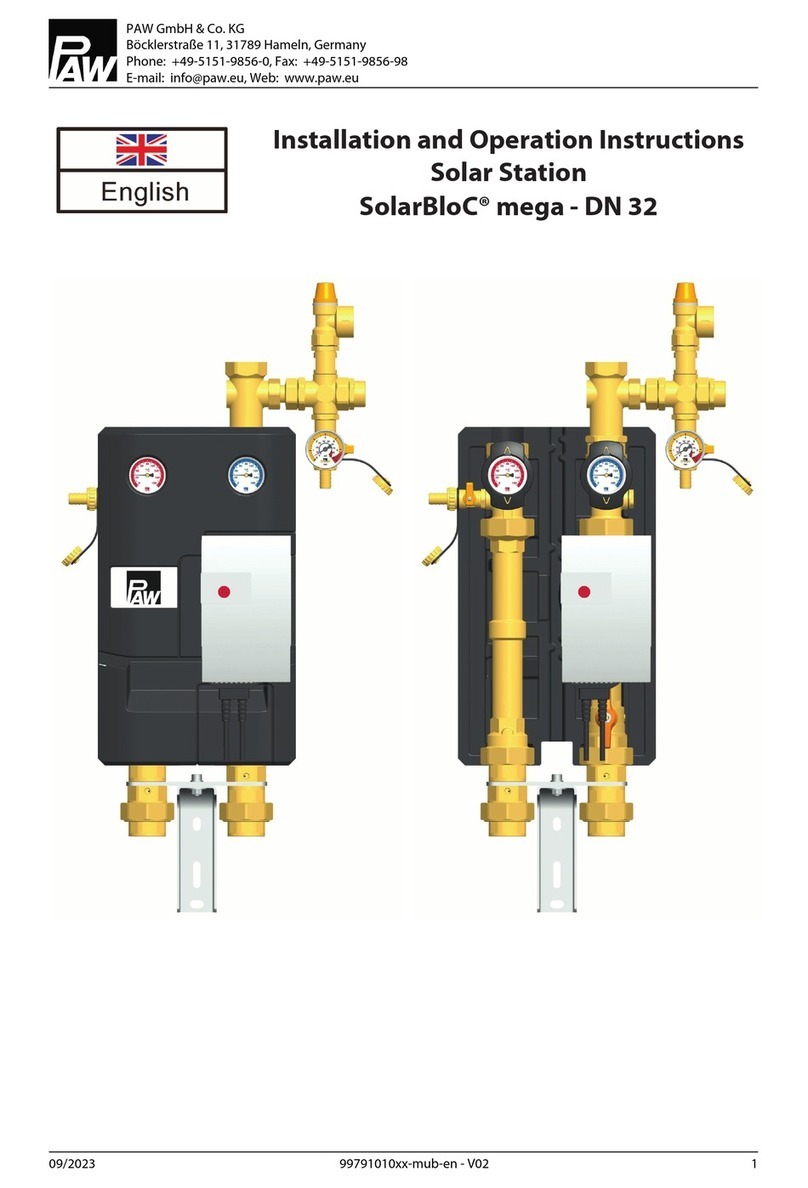

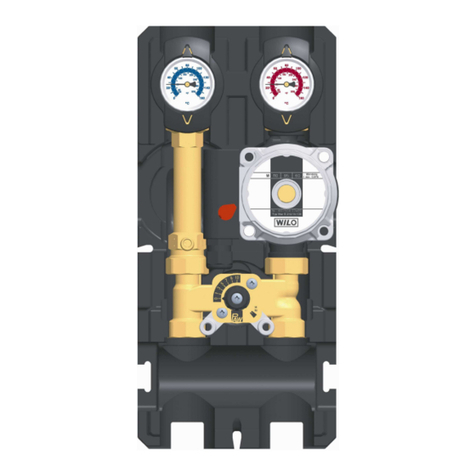

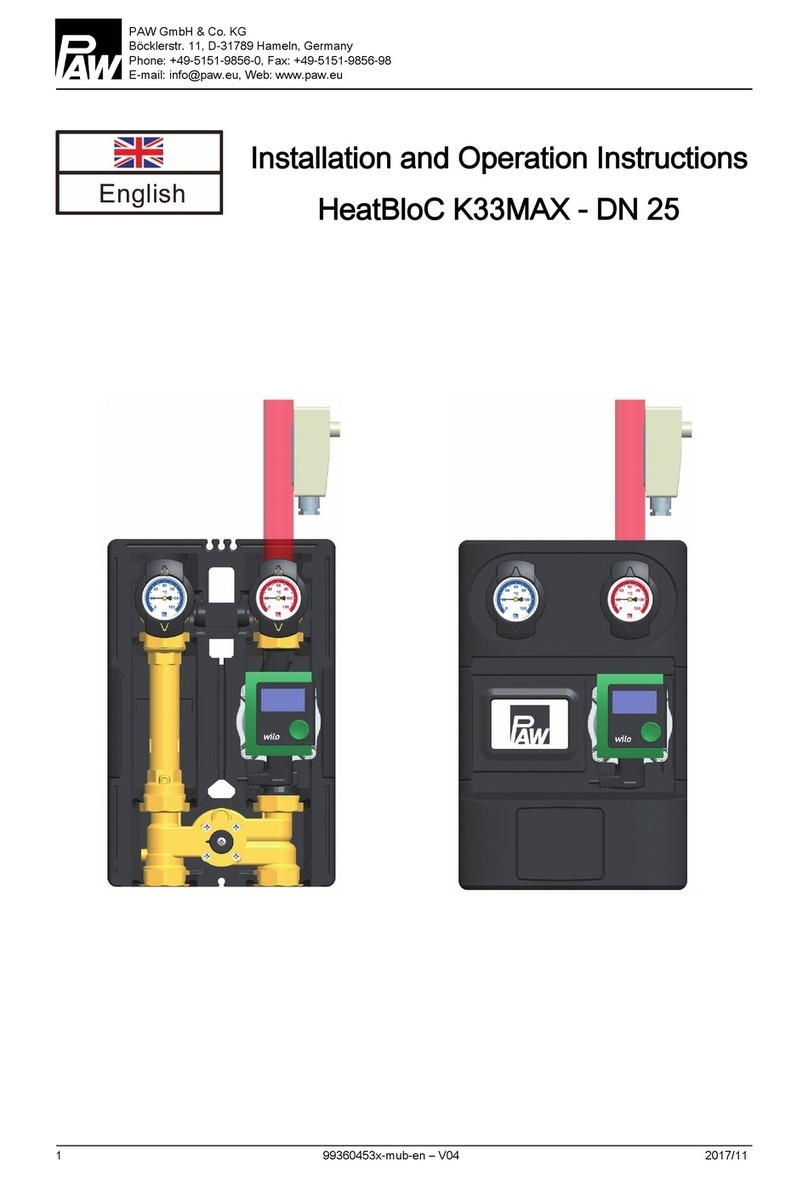

1.2 About this product......................................................................................................3

1.3 Designated use........................................................................................................... 4

2 Safety instructions......................................................................................................5

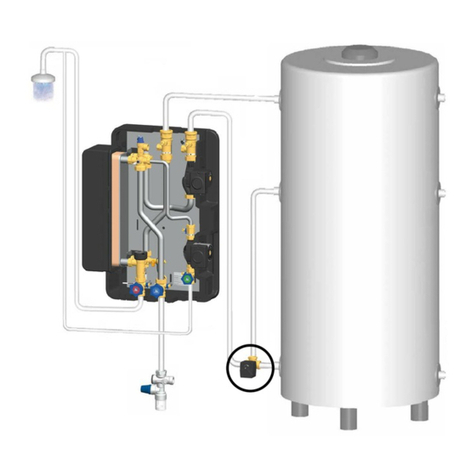

3 Mounting and installation [specialist]].....................................................................7

4 Commissioning [specialist]........................................................................................ 10

4.1 Flushing and filling the solar circuit..........................................................................11

4.2 Preparations before flushing.....................................................................................13

4.3 Flushing and filling.....................................................................................................13

4.4 Setting the solar installation..................................................................................... 15

5 Maintenance [specialist]............................................................................................ 16

5.1 Replacement / adjustment of the pressure gauge...................................................16

5.2 Draining the solar system.......................................................................................... 17

5.3 Deinstallation..............................................................................................................18

6 Scope of delivery [specialist]..................................................................................... 19

6.1 SolarBloC® midi Basic DN 20...................................................................................... 19

6.2 SolarBloC® maxi Basic DN 25..................................................................................... 21

6.3 SolarBloC® maxi Basic DN 25 for Grundfos Solar PML and Wilo Para MAXO.........23

7 Technical data............................................................................................................. 25

7.1 Dimensional drawing SolarBloC® midi Basic DN 20.................................................26

7.2 Dimensional drawing SolarBloC® maxi Basic DN 25................................................ 26

7.3 Pressure drop and pump characteristic curves SolarBloC® midi Basic DN 20....... 27

7.4 Pressure drop and pump characteristic curves SolarBloC® maxi Basic DN 25.......27

8 Function of the check valves [Expert]....................................................................... 28

9 Disposal....................................................................................................................... 30

10 Commissioning report................................................................................................31

Table of Contents

09/2023 9976x0210x-mub-en - V02 2