Table of Contents

1 General Information...................................................................................................3

1.1 Scope of these instructions........................................................................................3

1.2 Designated use........................................................................................................... 3

2 Safety instructions......................................................................................................4

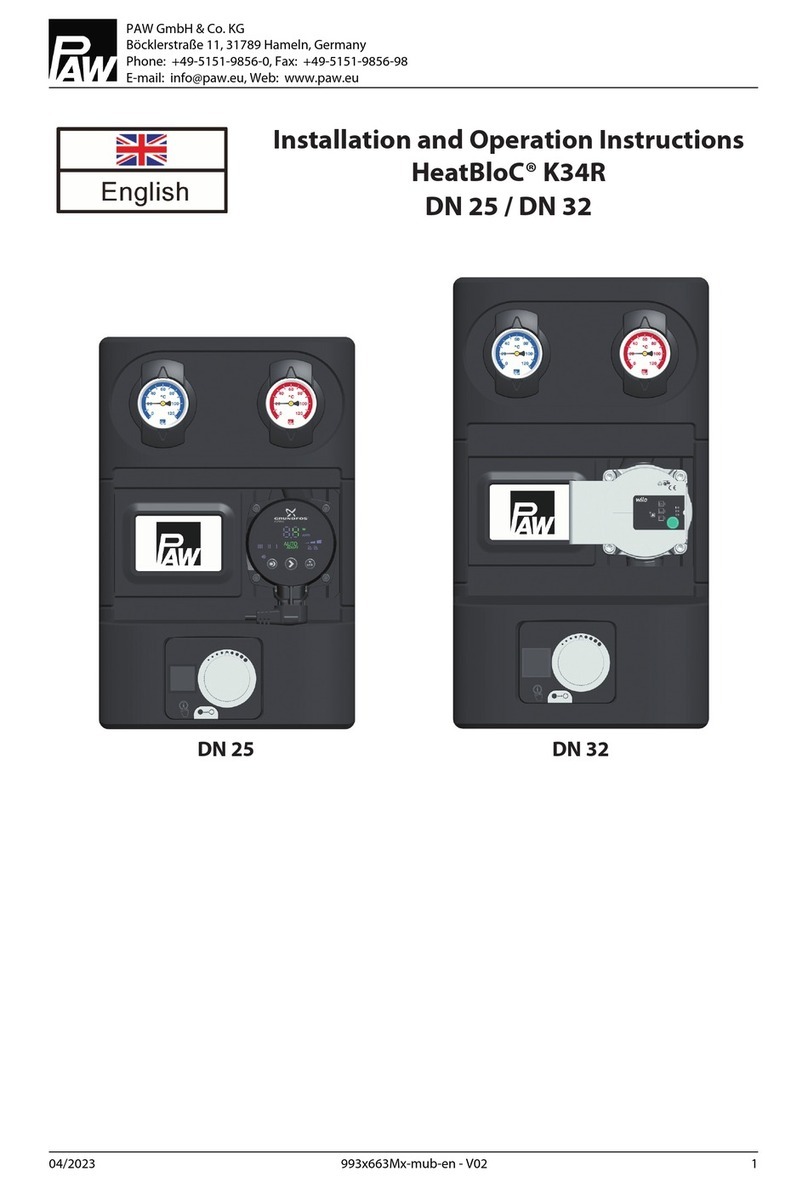

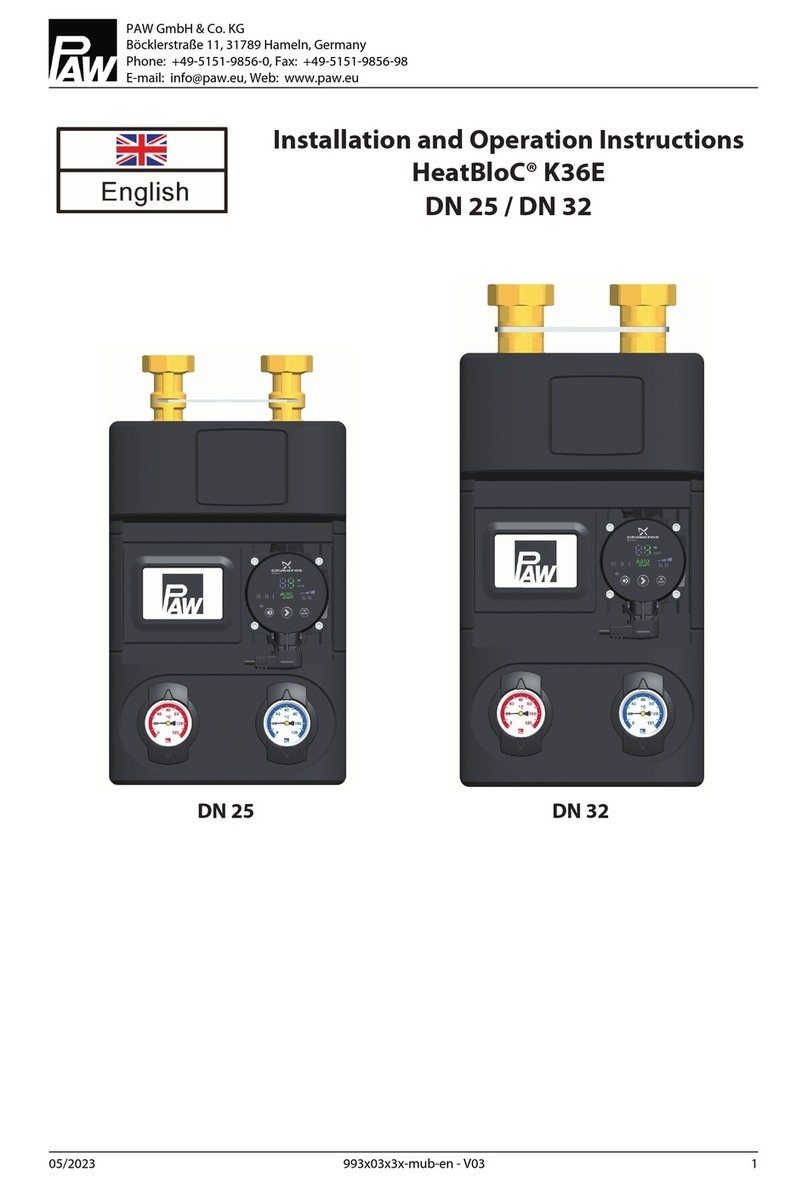

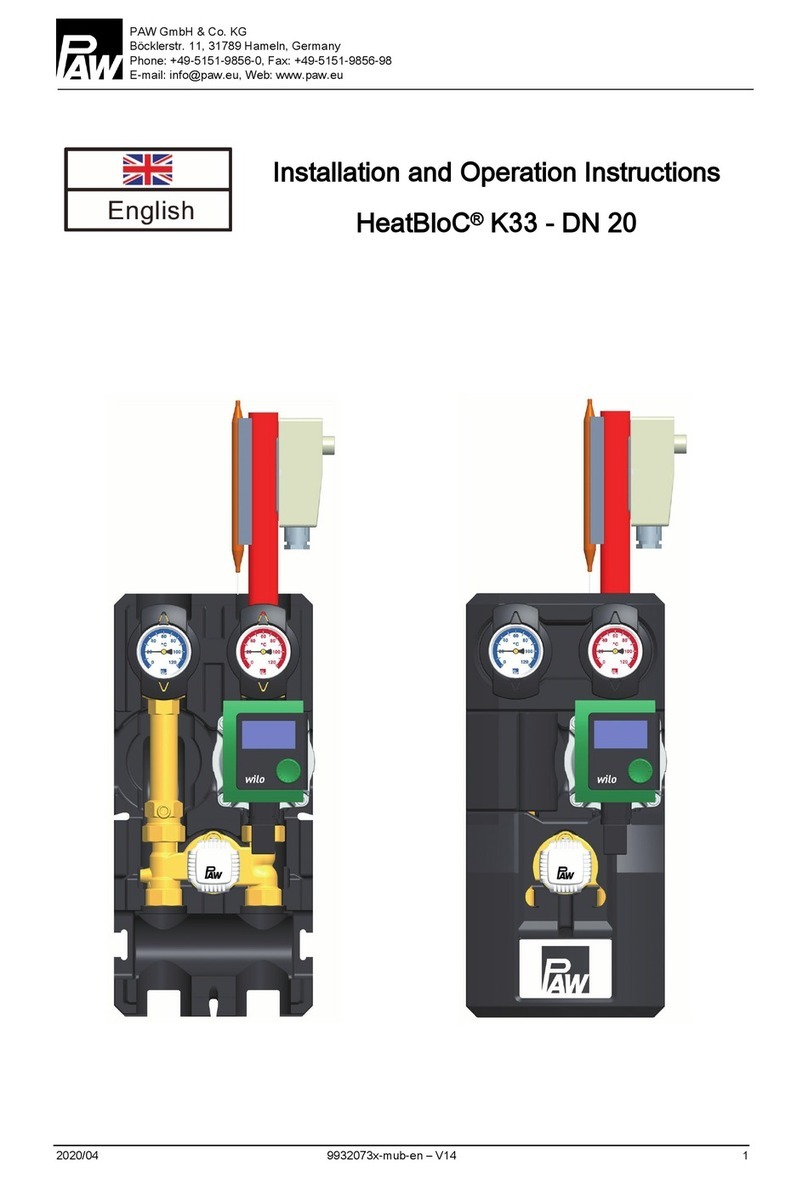

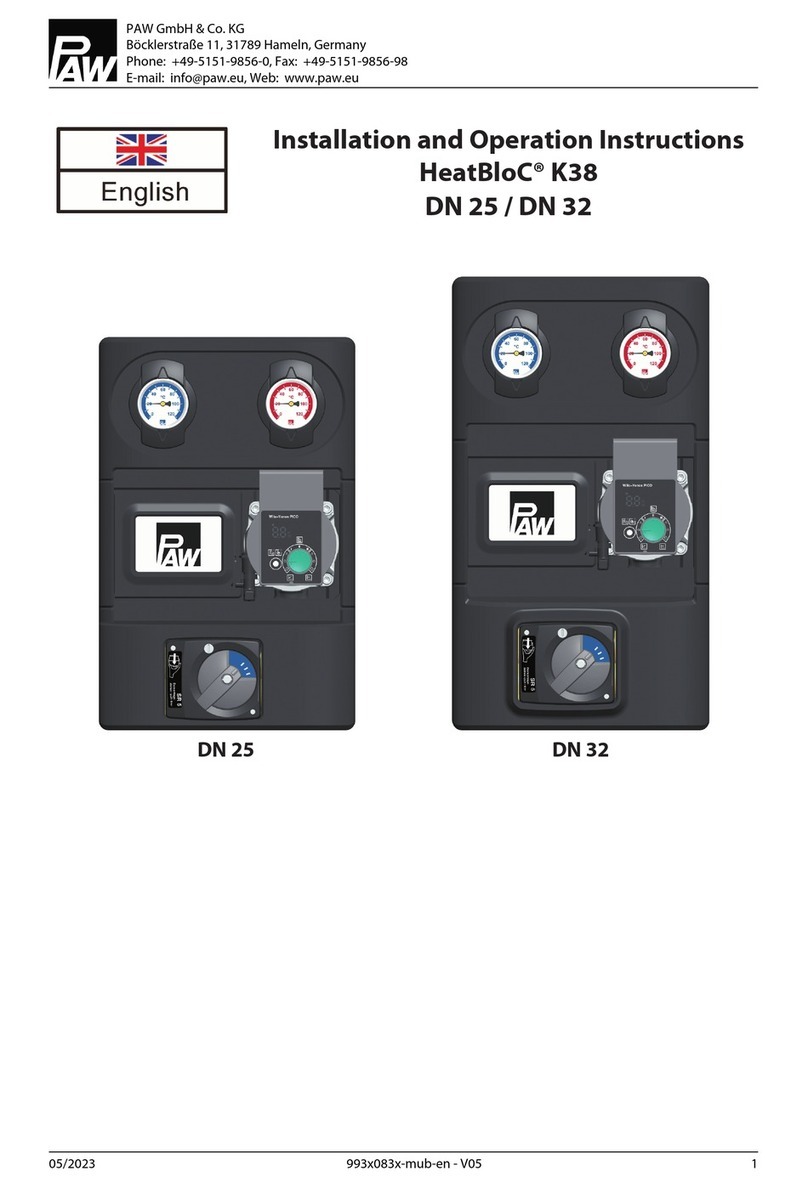

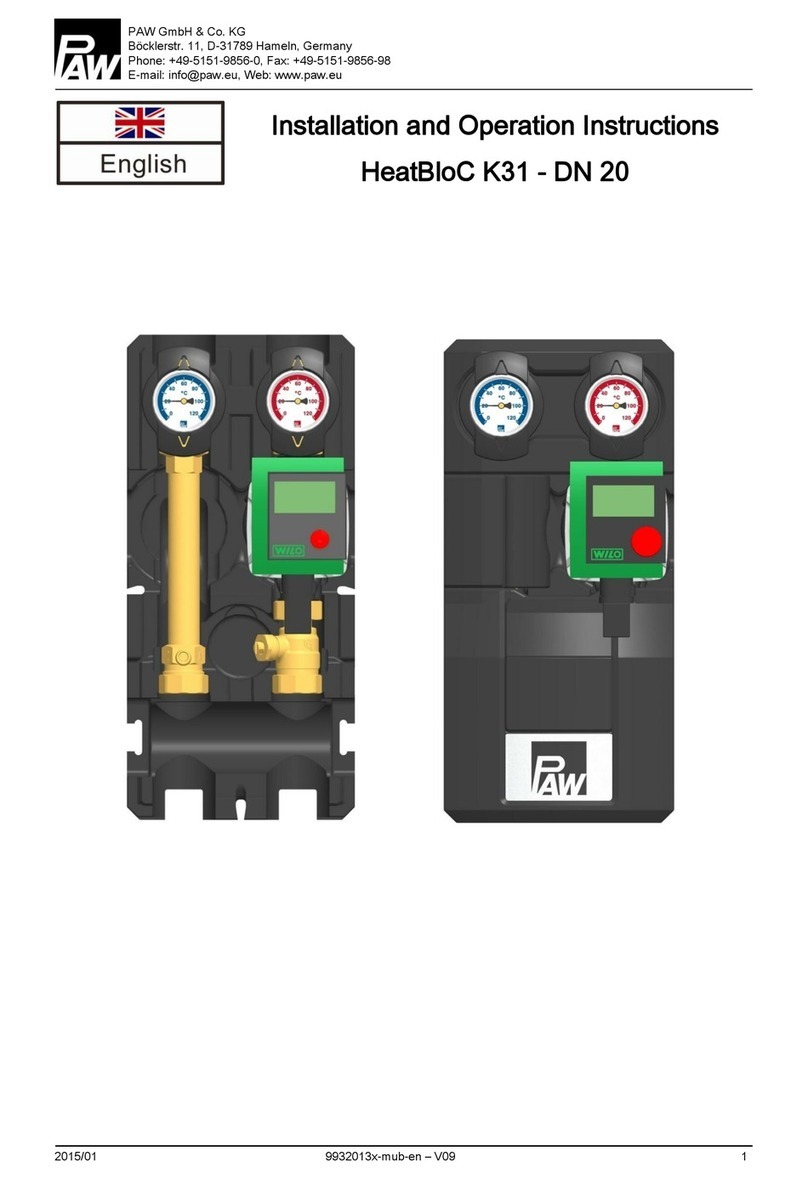

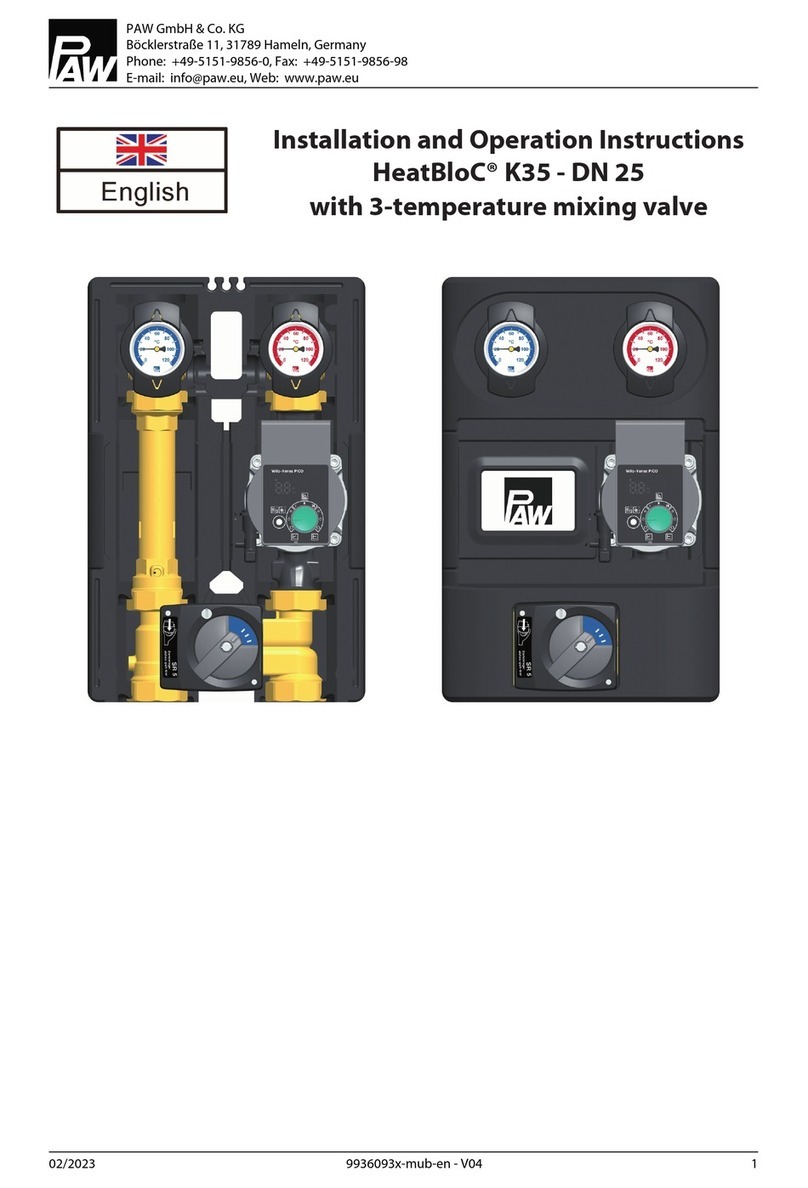

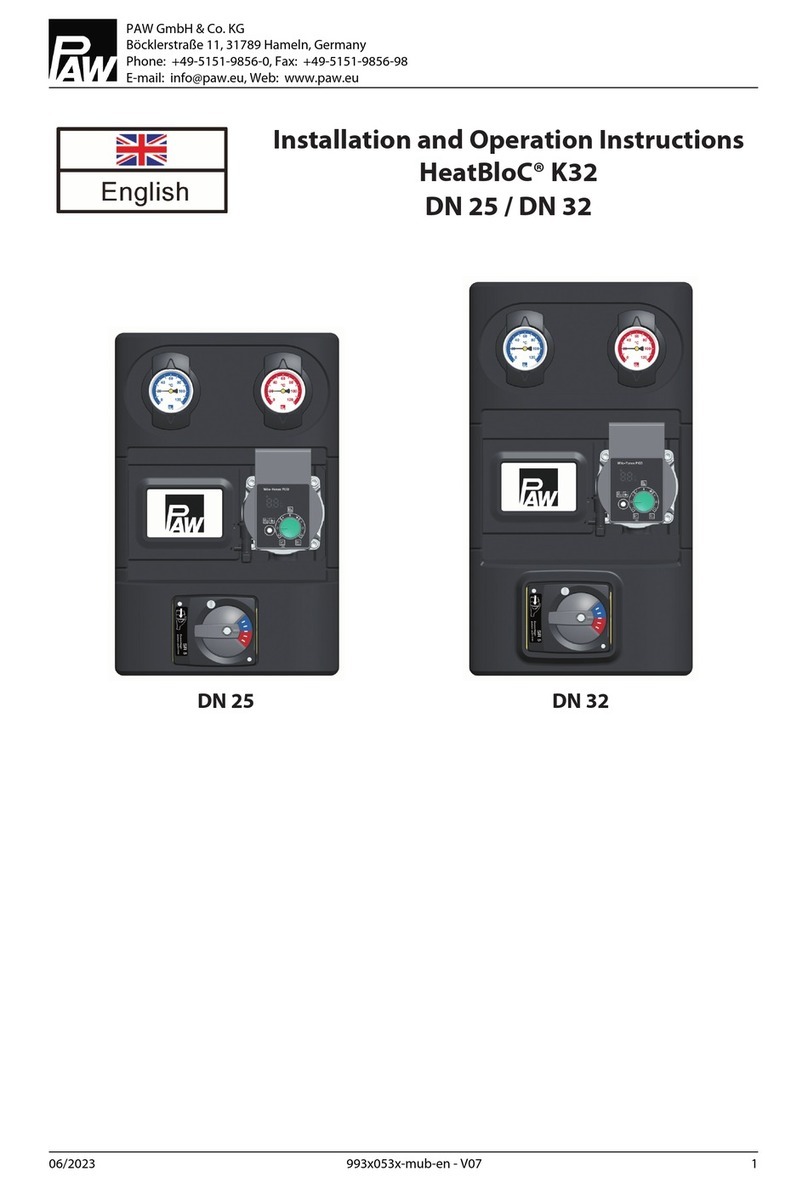

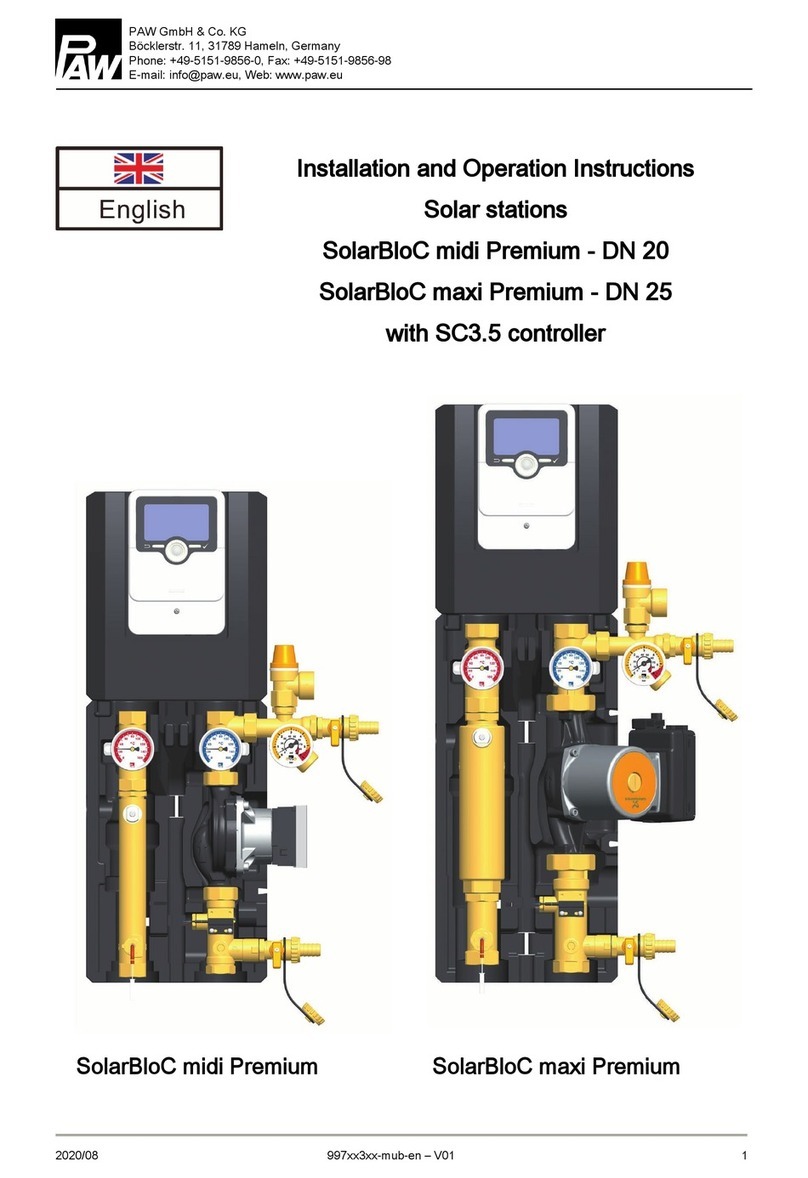

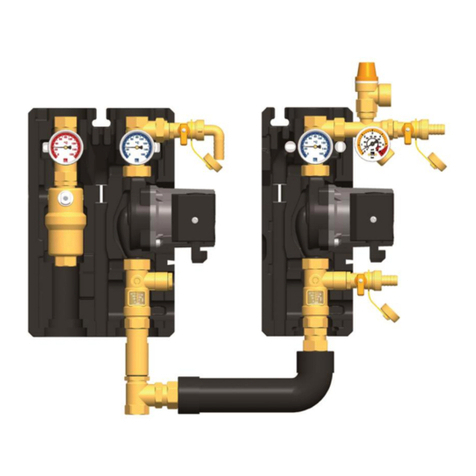

3 Product description.................................................................................................... 5

3.1 Equipment...................................................................................................................5

3.2 Function.......................................................................................................................6

3.2.1 Check valve................................................................................................................. 7

4 Mounting and installation [specialist]...................................................................... 8

4.1 Installation and commissioning of the HeatBloC®...................................................8

4.2 Accessories: Cutting-ring compression fitting (not included in the scope of

delivery).......................................................................................................................11

5 Scope of delivery [specialist]..................................................................................... 12

5.1 Spare parts DN 25....................................................................................................... 12

5.2 Spare parts DN 32....................................................................................................... 14

6 Technical data............................................................................................................. 16

6.1 Pressure drop and pump characteristic curves DN 25.............................................18

6.2 Pressure drop and pump characteristic curves DN 32.............................................18

7 Disposal....................................................................................................................... 19

Table of Contents

02/2023 993x013x-mub-en - V05 2