1 General Information

2020/08 997xx3xx-mub-en – V01 3

Contents

1General Information.........................................................................................................4

1.1 About these instructions ...............................................................................................4

1.2 About this product ........................................................................................................4

1.3 Designated use ............................................................................................................5

2Safety instructions ...........................................................................................................6

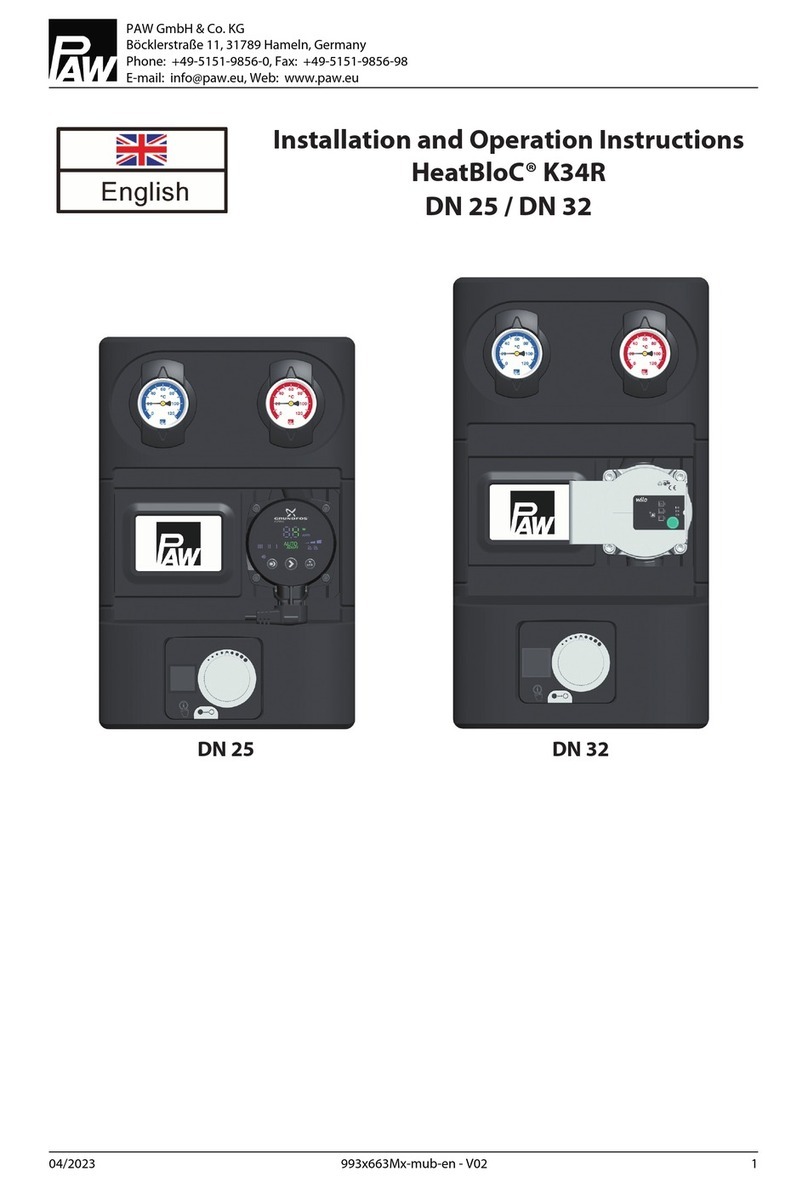

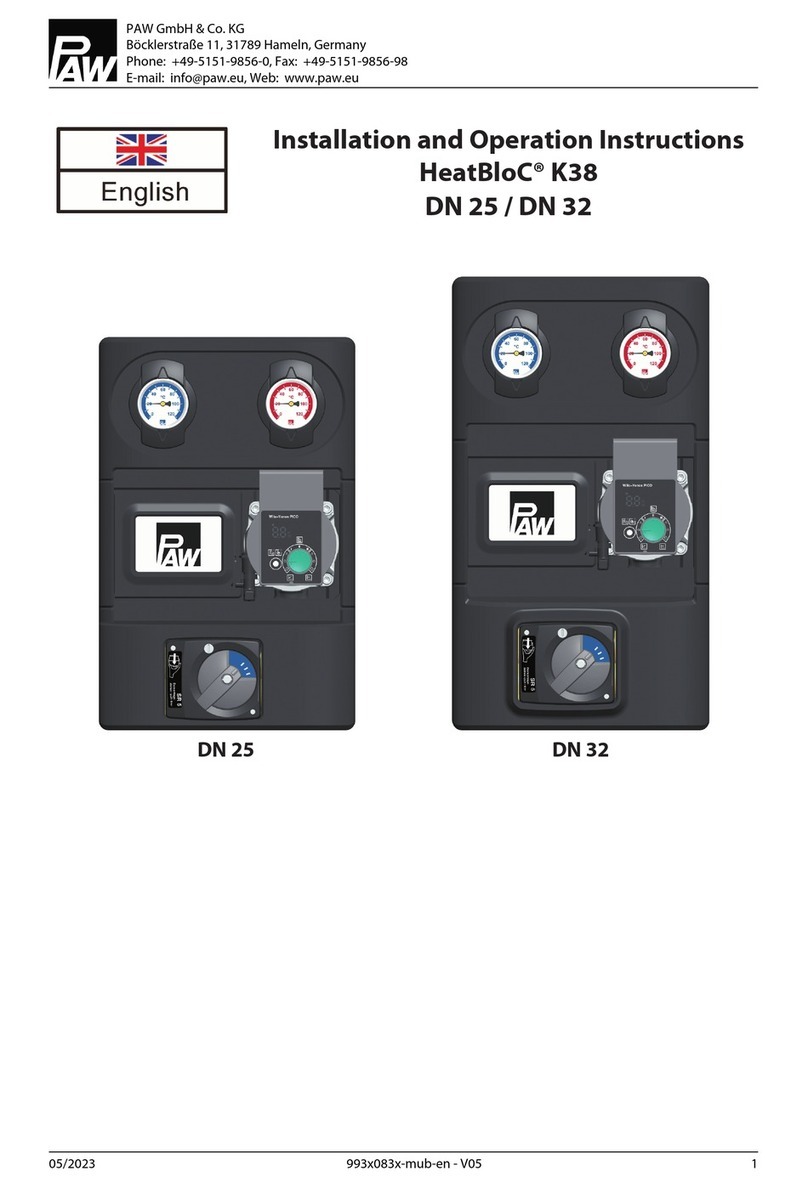

3Assembly and installation [specialist]................................................................................8

4Commissioning [specialist].............................................................................................11

4.1 Flushing and filling the solar circuit............................................................................. 12

4.2 Preparations before flushing....................................................................................... 14

4.3 Flushing and filling .....................................................................................................15

5Maintenance [specialist].................................................................................................17

5.1 Replacing the temperature sensor at the Airstop........................................................ 17

5.2 Draining the solar installation ..................................................................................... 18

5.3 Deinstallation..............................................................................................................18

6Spare parts [specialist] ..................................................................................................19

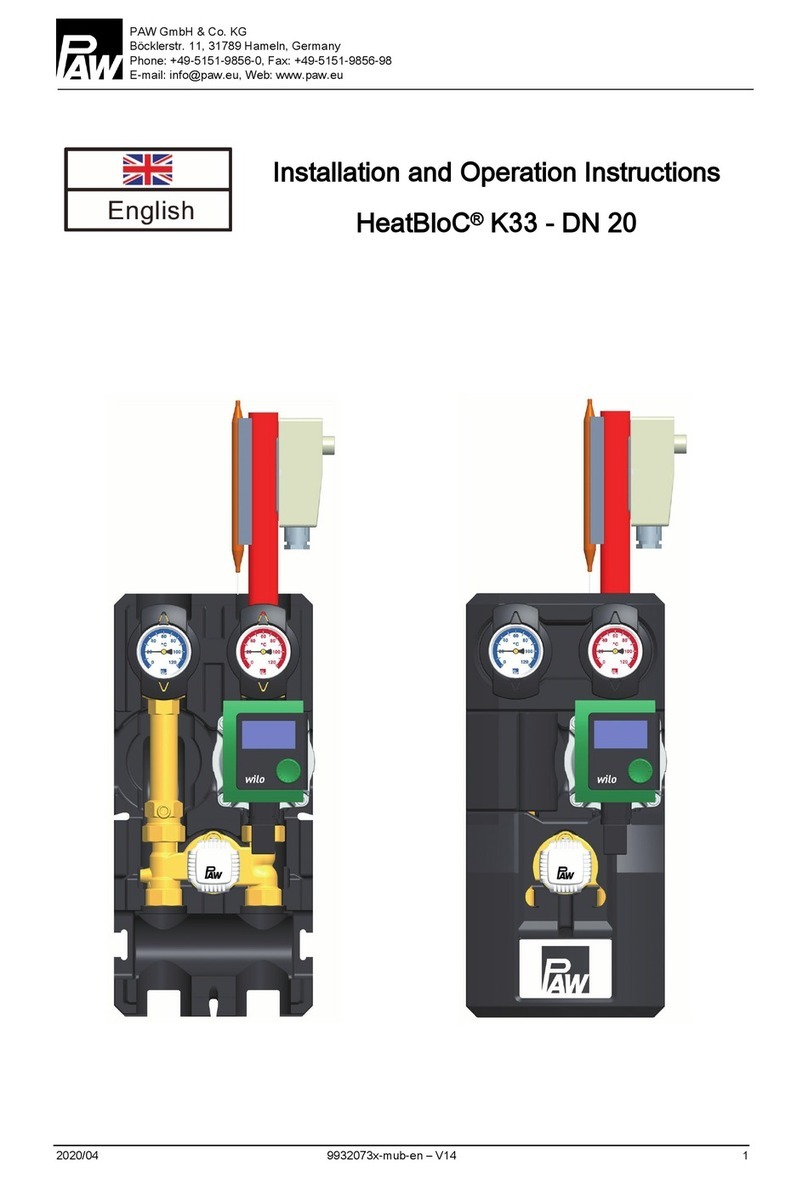

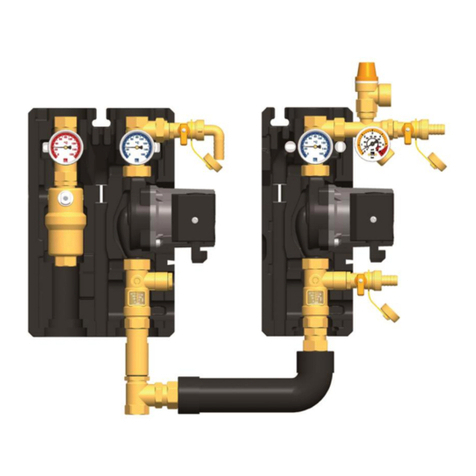

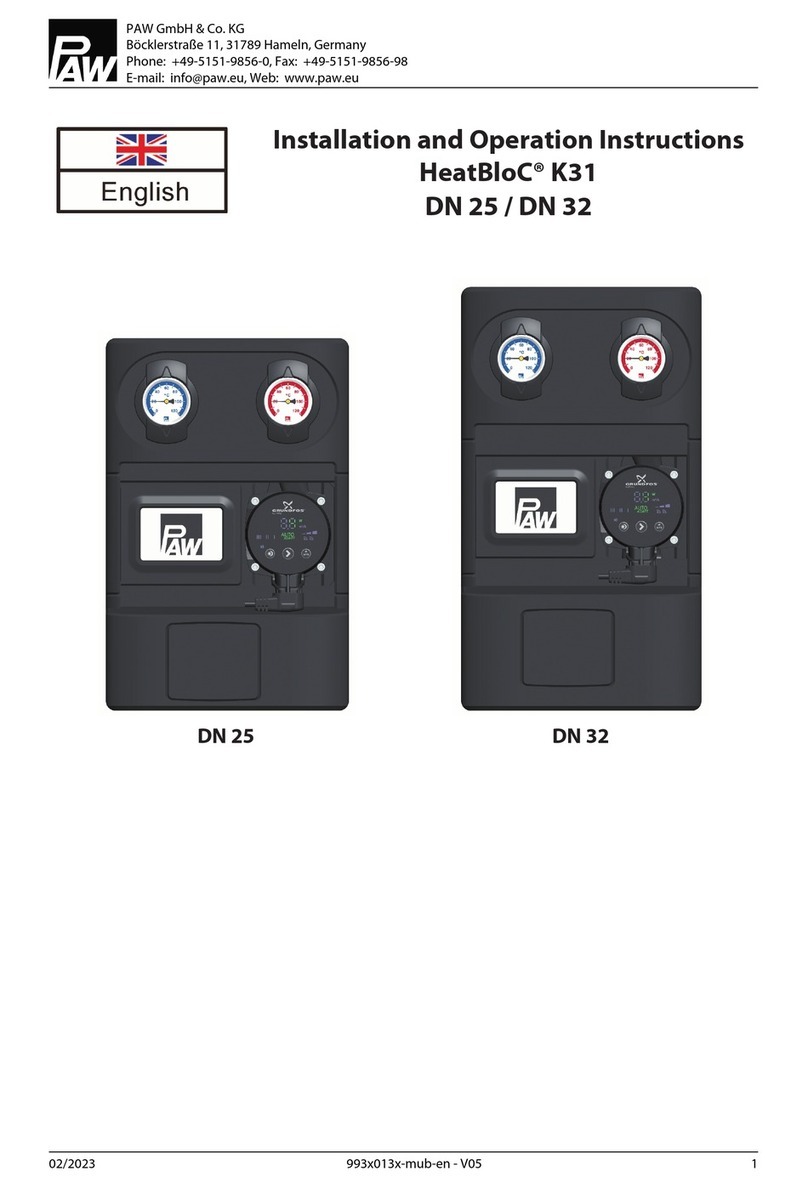

6.1 SolarBloC midi Premium DN 20 ................................................................................. 19

6.2 SolarBloC maxi Premium DN 25 ................................................................................ 21

6.3 Connection of the PWM pumps.................................................................................. 23

7Assembly of the insulation .............................................................................................23

8Technical data...............................................................................................................24

8.1 Dimensional drawing SolarBloC midi Premium (DN 20) ............................................. 25

8.2 Dimensional drawing SolarBloC maxi Premium (DN 25) ............................................ 25

8.3 Pressure drop and pump characteristic curves SolarBloC midi Premium (DN 20) ...... 26

8.4 Pressure drop and pump characteristic curves SolarBloC maxi Premium (DN 25) ..... 26

9Disposal........................................................................................................................27

10 Function of the check valves [Expert] .............................................................................28

11 Commissioning report....................................................................................................30