PAW K36E Owner's manual

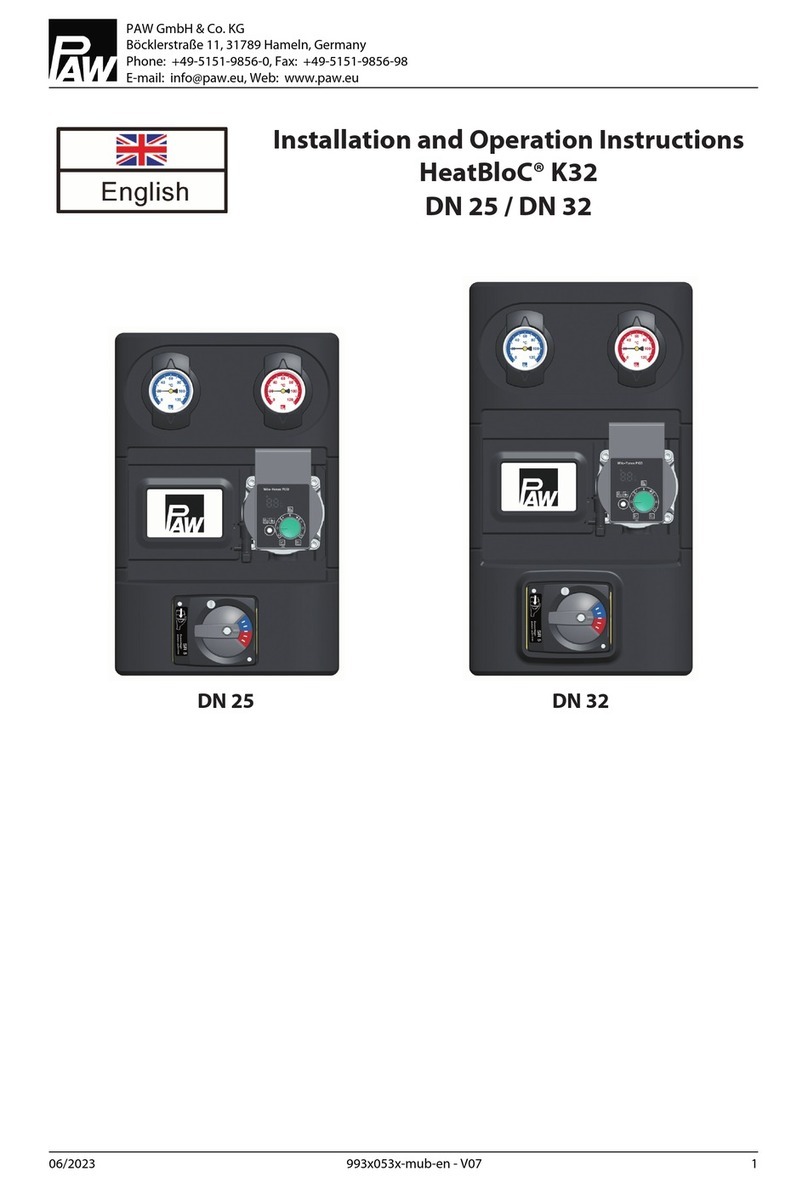

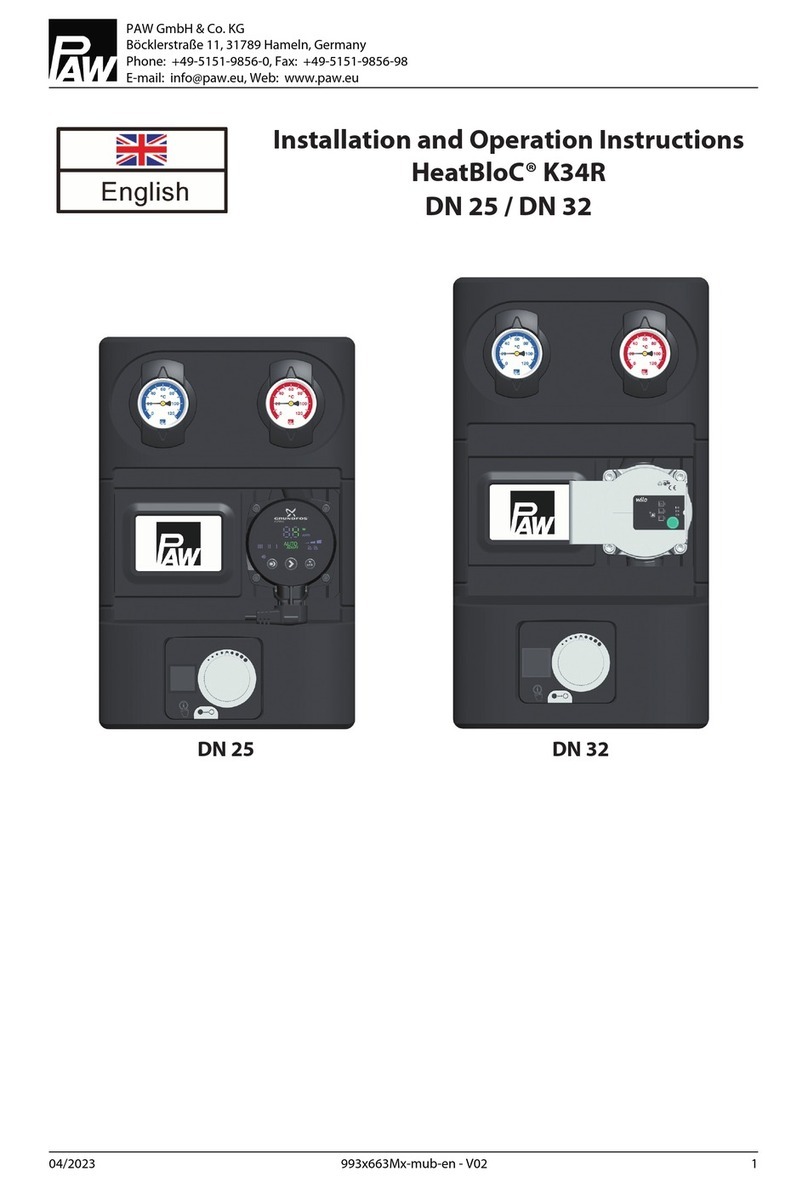

Installation and Operation Instructions

HeatBloC® K36E

DN 25 / DN 32

DN 25 DN 32

PAW GmbH & Co. KG

Böcklerstraße 11, 31789 Hameln, Germany

Phone: +49-5151-9856-0, Fax: +49-5151-9856-98

05/2023 993x03x3x-mub-en - V03 1

Table of Contents

1 General Information...................................................................................................3

1.1 Scope of these instructions........................................................................................3

1.2 Designated use........................................................................................................... 3

2 Safety instructions......................................................................................................4

3 Product description.................................................................................................... 5

3.1 Equipment...................................................................................................................5

3.2 Function.......................................................................................................................6

3.3 Thermo controller.......................................................................................................8

3.4 Check valve................................................................................................................. 11

4 Mounting and installation [specialist]].....................................................................12

4.1 Installation and commissioning of the HeatBloC®...................................................12

4.2 Accessories: Cutting-ring compression fitting (not included in the scope of

delivery).......................................................................................................................15

5 Scope of delivery [specialist]..................................................................................... 16

5.1 Spare parts DN 25....................................................................................................... 16

5.2 Spare parts DN 32....................................................................................................... 18

6 Technical data............................................................................................................. 20

6.1 Pressure drop and pump characteristic curves DN 25.............................................22

6.2 Pressure drop and pump characteristic curves DN 32.............................................22

7 Disposal....................................................................................................................... 23

Table of Contents

05/2023 993x03x3x-mub-en - V03 2

1 General Information

Carefully read these instructions before installation and commissioning. Save these

instructions in the vicinity of the installation for future reference.

1.1 Scope of these instructions

These instructions describe the installation, commissioning, function and the operation of the

HeatBloC® K36E DN 25 and DN 32.

For other components of the installation, such as the pump, the controller or the modular distribution

manifold, please observe the instructions of the corresponding manufacturer. The chapters called

[specialist] are intended for specialists only.

1.2 Designated use

The product may only be used in heating circuits taking into consideration the technical limit values

indicated in these instructions.

It must not be used in drinking water applications.

Improper usage excludes any liability claims.

This product complies with the relevant directives and is therefore labelled with the CE mark.

The Declaration of Conformity is available upon request, please contact the manufacturer.

Only use PAW accessories with the product.

1 General Information

05/2023 993x03x3x-mub-en - V03 3

2 Safety instructions

The installation and commissioning as well as the connection of electrical components require

technical knowledge commensurate with a recognised vocational qualification as a fitter for

plumbing, heating and air conditioning technology, or a profession requiring a comparable level of

knowledge [specialist].

The following must be observed during installation and commissioning:

●relevant local and national regulations

●accident prevention regulations of the professional association

●instructions and safety instructions mentioned in these instructions

CAUTION

Personal injury and damage to property!

The product must only be used in heating circuits filled with heating water according

to VDI 2035 / Ö-Norm H 5195-1.

►The product must not be used in drinking water applications.

NOTICE

Material damage due to mineral oils!

Mineral oil products cause lasting damage to seals made of EPDM, whereby the sealant properties

are lost. We do not assume liability nor provide warranty for damage to property resulting from

sealants damaged in this way.

►It is imperative to prevent the EPDM sealing elements from making contact with substances

containing mineral oils.

►Use a silicone- or polyalkylene-based lubricant free of mineral oil such as Unisilikon L250L

and Syntheso Glep 1 from Klüber or a silicone spray.

2 Safety instructions

4 993x03x3x-mub-en - V03 05/2023

3 Product description

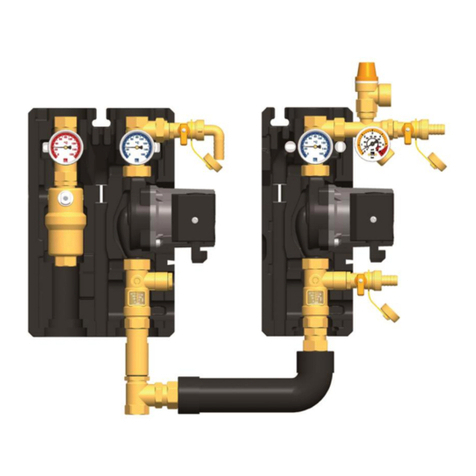

The HeatBloC® K36E (boiler charging set) is a preassembled fitting group for boiler circuits. The pump

can be isolated by means of the ball valves and maintenance work on the pump can thus be carried

out without draining the boiler circuit.

You can mount the PAW HeatBloC® directly onto a wall bracket or under/on a PAW modular

distribution manifold. With transition connections, PAW HeatBloC®s can also be mounted under/on

PAW modular distribution manifolds of other dimensions.

3.1 Equipment

A-1 Return from the consumer circuit

A-2 Thermo controller with adjustable overflow

valve

B Heating pump

C-1 Return to the heat generator

C-2 Full metal thermometer integrated in the ball

valve (return, blue)

D-1 Flow from the heat generator

D-2 Full metal thermometer integrated in the ball

valve (flow, red)

E Flow pipe

F Design insulation with optimised function

G-1 Flow to the consumer circuit

G-2 Check valve, can be opened

G-3 Coupling piece for overhead installation

3 Product description

05/2023 993x03x3x-mub-en - V03 5

3.2 Function

Boiler charging set for the return flow temperature

maintenance of solid fuel boilers, wood firing and

stove heating systems

The boiler charging set prevents the temperature in the

boiler from falling under the dew point, thus reducing the

contamination of the boiler.

Application ranges:

●The boiler charging set can be mounted to a buffer

tank or to a hydraulic separator. If the opening

temperature of 45 °C or 60 °C is reached in the

boiler circuit, the performance of the boiler can be

used to charge the tank or the hydraulic separator.

The following figure shows the adjustments necessary for

this system.

3 Product description

6 993x03x3x-mub-en - V03 05/2023

●The boiler charging set can be mounted under/on

a distribution manifold. In this system the pump

exerts a pressure on the entire installation. When

the overflow valve in the thermo controller is open,

the pressure can be reduced via the valve.

Undesired circulation, which could lead to

overcharging of the domestic water tank, can thus

be prevented.

The following figure shows the adjustments necessary for

this system.

3 Product description

05/2023 993x03x3x-mub-en - V03 7

3.3 Thermo controller

The thermo controller is equipped with an overflow valve and a thermal control valve.

Overflow valve

In systems with a distribution manifold, the pump of the boiler charging set exerts an initial pressure

on the entire installation. If the overflow valve of the thermo controller is open, the pressure can be

reduced via the valve. Undesired circulation, which could lead to an overcharging of the domestic hot

water tank, can thus be prevented.

Overflow valve open

close

Overflow valve closed

open

3 Product description

8 993x03x3x-mub-en - V03 05/2023

Thermal control valve

The thermal control valve serves as a bypass in the startup phase.

1. If the water temperature in the boiler circuit is lower than the

opening temperature of the thermal control valve, this valve is

closed and thus also the line to the consumers. The water

circulates in the boiler circuit via the completely open bypass.

2. As soon as the water in the boiler circuit has reached the

opening temperature (+/- 3 K), the thermal control valve starts

opening the line from/to the consumers. This enables the

circulation in the consumer circuit. The cold water from the

consumer return line is mixed with the hot water from the

bypass at the control valve. Depending on the temperature and

the flow rate of the water from the return line, the thermal

control valve shuts or opens the line to the consumers. Thus, the

return to the boiler always remains at a certain temperature

level.

3. With increasing temperature in the return line of the consumers,

the thermal control valve completely opens the line to the

consumers. During operation, the temperature of the return of

the boiler remains nearly constant (+/ -3 K), until the buffer tank

is completely charged.

3 Product description

05/2023 993x03x3x-mub-en - V03 9

Change of the flow line [specialist]

1. Take off the thermometer handles (C-2, D-2) and

remove the insulating front shells.

2. Take the group of fittings out of the insulating

back shell.

3. Loosen the union nuts at the thermo

controller (A-2).

4. Dismount the thermo controller and turn it

by 180° around the vertical axis.

Retrofitting and commissioning of the heating

circuit

1. Interchange the flow line with the return line and

the pump (B).

2. Re-install the thermo controller and tighten the

union nuts.

Consider the flow direction of the pump!

Turn the pump head such that the terminal box

is directed to the top or to the centre of the

group of fittings.

3. Mount the HeatBloC® and connect it to the

installation.

4. Check all union nuts before commissioning and

firmly tighten them if necessary.

5. Mount the insulation only after having carried

out a pressure test. Mount the thermometer

handles (C-2, D-2) in a final step.

3 Product description

10 993x03x3x-mub-en - V03 05/2023

Other manuals for K36E

2

Table of contents

Other PAW Industrial Equipment manuals

PAW

PAW HeatBloC K38 Owner's manual

PAW

PAW MB3.10 Owner's manual

PAW

PAW HeatBloC K31 - DN 20 Owner's manual

PAW

PAW SolarBloC midi 2D Installation and operation manual

PAW

PAW K35 Owner's manual

PAW

PAW HeatBloC K32 Owner's manual

PAW

PAW HeatBloC K31 Owner's manual

PAW

PAW SolarBloC midi 2S Installation and operation manual

PAW

PAW HeatBloC K31 - DN 20 Owner's manual

PAW

PAW HeatBloC K34R Owner's manual