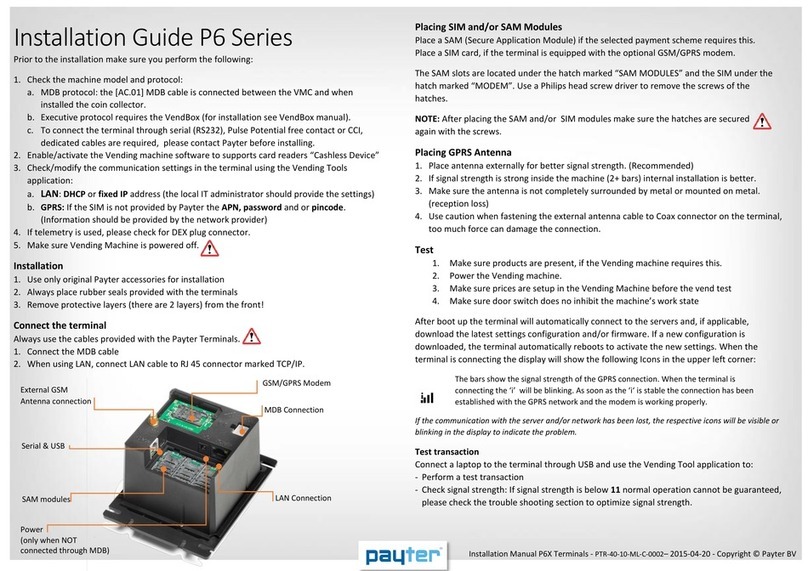

Paytec Apex 7000 User manual

rev. AB 02/2018

APEX 7000

MDB BILL ACCEPTOR

User Guide

2

Contents

General warning .................................................................................................................................................3

Product overview ................................................................................................................................................3

Technical description ..........................................................................................................................................3

Installation...........................................................................................................................................................4

Front bezel lights and diagnostic messages.......................................................................................................5

Firmware update .................................................................................................................................................6

Maintenance .......................................................................................................................................................6

Cleaning instructions ..........................................................................................................................................7

Dimensions .......................................................................................................................................................11

The information contained in this user guide is subject to change without prior notice and is not binding for

Payment Technologies S.r.l.

APEX 7000 is distributed by Paytec.

3

General warning

•

Read this guide carefully before use.

•

Before APEX 7000 is installed, check voltage compatibility with the Vending Machine.

•

The product has been designed as internal equipment.

•

Do not use in water or near liquids where it might become wet.

•

Do not use near smoke or inflammable gases.

•

Cut power before maintaining electrical and/or mechanical components.

•

Dispose of the device in accordance with environmental laws (DO NOT burn).

•

Always read labels.

•

Do not tie the system main cables or cables belonging to slave units.

•

Periodically check whether cables are correctly plugged on their connectors.

•

Cut power before maintaining and/or cleaning the unit.

•

Use a damp cloth to clean plastic elements.

Product overview

APEX 7000 is a MDB Bill Acceptor, meeting the standards required by MDB protocol.

The product is available with 200 bill- and 500 bill-stacker.

The “Escrow” function enables users to get the bill back in the case of a failed vend or when no change is

available.

The bill validation module can be removed to make cleaning operations easier. An optical anti-stringing

technology.grants the highest security.

It is possible to enable single bills quickly by toggling the DIP switches on board.

The product is equipped with pushbutton for diagnostic purposes and front bezel lights for a correct interpretation

of diagnostic signals (the number of times the lights flash corresponds to the error code).

Apex 7000 can the updated with the handheld device PRO-2.

Technical description

Operating voltage: 34V DC unstabilized (rectified and filtered)

24V DC rms (rectified)

Voltage rate: 20V DC min.; 40V DC max.

Operating currents: 180 mA (idle), 500 mA (accepting), 1,50 A (stalled)

Operating temperature: 0°C – 60°C, 90% non-condensing humidity.

Acceptance rate: > 95% including second time insertion of a rejected bill.

Acceptance speed: approx. 20 bills per minute

Sensor array: 8 Optical Sensors

Bills accepted: up to 12 bills in all four directions - up to 72 mm wide

Net weight:

2.3 lbs./1.04 kg

(with 200-bill stacker)

Stacker capacity: 200 (standard) or 500 bills

4

Installation

Apex 7000 can be configured by toggling the position of the DIP switches on the bottom of the unit.

Toggle the switches to ON or OFF position to decide which bills are to be accepted and the insertion side.

Switch 1 – 4: Enabling single bills

By toggling DIP switches 1 through 4 to ON or OFF position, you

enable or disable bills 1, 2 and 3 (in increasing order). The 4

th

switch

is not used.

Example: if you wish to accept only bills 1 and 2, simply toggle DIP

positions 1 and 2 to the ON position, and set 3 and 4 to OFF.

Switch 5: Limiting Acceptance Directions

To accept bills in all 4 insertion directions, toggle DIP position 5 to the

ON position. To limit acceptance to left-end, face-up only insertion, toggle

DIP position 5 to the OFF position.

Switch 6: Acceptor Enable Mode

Toggle DIP switch 5 to the OFF position

Switch 7: “Pulses Per Dollar”

Unused – must be toggled to OFF position

Switch 8: “Pulse Speed Setting”

Unused – must be toggled to OFF position

When power is given, the bill acceptor will cycle its motor and stacker. Check the bezel lighting. If the serial line

MDB is ON, the front bezel lights will be flashing.

Should the acceptor be inhibited (by a Master unit) or the serial line MDB is cut, the front bezel lights will be OFF.

FRONT BEZEL

LIGHTS

5

Front bezel lights and diagnostic messages

Apex 7000 has built-in diagnostic abilities. These can be accessed using the Diagnostic Pushbutton located on

the bottom right side of the bill acceptor (under the label "

DIAGNOSTIC PUSH BUTTON

").

To enter the Diagnostic Mode, push and hold the Diagnostic Pushbutton for at least one (1) second, then

release. The front bezel lights will be ON or flashing.

The lights steady ON means that no error has been detected.

If the lights start flashing, the number of times the lights flash corresponds to the error code listed here below.

Always cut power before cleaning the bill path or the stacker.

The acceptor will automatically exit Diagnostic Mode when it remains idle for thirty (30) seconds, or you can press

the Pushbutton again and keep it pressed for 1 to 5 seconds.

No.

flashings Error What to do

1 Bill jammed or something is in the bill

path.

Remove the stacker and Lower Transport to inspect for

foreign objects. Clean if necessary.

2 Something is obstructing the stacker. Remove the stacker and Lower Transport to inspect for

foreign objects. Clean if necessary.

3 The stacker is full of bills. Remove the stacker and empty it.

4 The stacker has been removed. Replace the stacker.

5 The acceptor is defective. Replace the acceptor.

6 Acceptor inhibited by master MDB. Check setup of the master system (Host).

8 CPU error. Repeat firmware updating. If the error is repeated, contact

Paytec Customer Service.

Flashing

quickly

The acceptor has detected a stringing

attempt, or the optical anti-stringing

sensor is dirty.

Remove the Lower Transport and clean the optical anti-

stringing sensor pair openings. It is a good idea to clean all

of the sensors at this time, both the entire upper and lower

halves of the bill path.

6

Firmware update

The firmware of APEX 7000 can be updated with the handheld programmer “PRO-2” (optional).

Connect “PRO-2” to the 6-pole connector located on the right side of the acceptor (under the label "

FLASH

MEMORY PORT

").

The programmer must be connected to a PC to load the correct firmware file, then disconnect PRO-2 from the

PC. After the firmware file has been successfully loaded on PRO-2, the bill acceptor can be easily updated with

PRO-2 on site (there is no need to have the PC at hand).

For more detailed info, please read “PRO-2” user guide.

Maintenance

The Apex bill acceptor is relatively maintenance free. An occasional cleaning is all that is needed to keep the

acceptor in top operation.

To clean the acceptor:

•

Remove power from the machine or unplug the MDB cable from the bill acceptor.

•

Unlatch the stacker by pushing in the yellow top latch and lifting the stacker up and out.

•

Remove the Lower Transport by pushing in the latch located on the bottom of the acceptor at the rear.

Gently pull the Lower Transport out of the assembly.

•

Clean the bill path using a soft cloth or towel.

•

Always use water.

•

If 100% water is not enough, use a mixture of water and alcool (80% water and 20% alcool).

•

Never use oils, benzene, or silicon spray on any part of the acceptor!

7

Cleaning instructions

Step 1:

Remove the stacker from the unit being serviced as indicated here below:

1. Depress the stacker latch by pulling it towards the front of the bill acceptor

2. With the latch depressed slide the stacker up

3. Now with the stacker slid up you can remove by pulling it out away from the validator.

8

Step 2:

With the stacker removed, locate the two white plastic ball bearings located on the face of the stacker pointed in

towards the validator when installed.

These plastic ball bearings can get fouled with lint, paper, dust and dirt.

Clean if any is present as this can cause the bearings to not make full

contact with the bill or completely stop it from moving (see left).

This kind of condition will create bill jams, possibly leaving the bottom of a

bill slightly outside of the cash box and not fully stacked. Dampen a lint

free cloth with water (only enough water to pick up dust) and run the cloth

up and down over the bearings until all debris is cleared.

If it is found to have a depressed ball and was not solved by the cleaning,

it will need to be replaced as this can cause a jam in the cash box (see

below)

Ball depressed that

needs replacing

9

Step 3: Bill path plate cleaning

We recommend disconnecting all power and I/O connectors from the validator at this point. If any side connectors

are still installed this could prevent you from fully removing the bottom plate without causing any damage to the

validator.

No tools are required to pull the bill path plate out. There is a recessed latch that must be pushed in to release

the plate. While pushing the latch in with your thumb, pull the plate straight back out of the main frame of the bill

acceptor as seen in the image below.

Fase 4: Bill path plate cleaning (2)

Once the plate is fully removed you will have full access to all the validation and side scan anti stringing lenses.

Inspect the plate for dust, dirt, smoke and debris. There are four round lenses and two oval lenses in the plate

that must be cleaned. Dampen a lint free cloth with water, only enough water to pick up dust. Using the damp

cloth wipe it over all lenses and roller until clean.

Side Scan Anti-Stringing

Gray Scale Lens

Validation Lenses

10

Step 5: Cleaning internal components

Directly above the plate inside the validator, there is another set four round and oval lenses that beam back and

forth to each other in the bill path plate as seen in the image below. Dampen a lint free cloth with water, only

enough water to pick up dust and run the cloth over all lenses and rollers until clean.

NOTICE: Sidescan, grey lenses and cash box sensor

Use the images below to locate the side scan anti stringing, grey lenses and cash box sensor. Be sure to keep

these lenses clean and debris free. If smoke or dirt builds up in these areas, bill acceptance and performance will

lower and bill rejects will become more frequent. In certain cases water may not be enough to clean the surfaces.

We recommend a solution of water and alcool (80% water and 20% alcool). This solution can also be used to

clean the drive belts if they are extremely dirty.

** NEVER USE OILS, BENZENE OR SILICON SPRAY ON ANY PART OF THE ACCEPTOR **

REAR CASH BOX

SENSOR

GRAY SCALE LENS

11

Dimensions

12

Payment Technologies S.r.l.

Via XX settembre, 49

22069 Rovellasca (CO)

Italy

Tel. +39 02 9696141

Fax +39 02 96961414

www.paytec.it

Table of contents

Other Paytec Touch Terminal manuals