PCC AVK AL Series Instructions for use

AVK INDUSTRIAL PRODUCTS

IJ!'!~

AriAieompany

THREADED INSERTS FOR INDUSTRV

z

c

c:

en

-f

JJ

:J>

r-

-f

::I:

JJ

m

:J>

c

m

c

-

z

en

m

JJ

-f

en

lNTBODUCTIQN .• ".

Read manual before operating tool.

You now own the finest insert installation tool on the market today. These durable tools provide many years of trouble free

operation if you will simply follow the instructions in this manual.

Prior to use, certain checks must be made. This tool requires the proper air line setup, lubrication, and air pressure to set the

desired inserts.

AIRf~IH§::IErUP

Every ARO Air Tool is designed and built to yield the longest possible useful life, with a minimum amount of servicing. Since an air

tool is a precision machine whose working parts mate with close tolerances, it should receive the same reasonable care as any

other machine tool. Here are a few simple practices that will keep your ARO Air Tool in top operating condition.

KEEP AIR SUPPLY CLEAN. All compressed air carries varying amounts of dust, scale, moisture and other foreign matter that

should be removed by proper filtering. Failure to keep air supply clean will result in excessive wear on working parts. Therefore,

we recommend the installation of an air line filter. If your tool is equipped with a built-in air strainer, remove and clean the strainer

periodically. Always blowout the air hose before attaching to tool.

LtJ~lil~I,Oftf··

USE AIR LINE LUBRICATOR. Air tool motors operate at extremely high speeds, and must have proper oil lubrication. An air line

lubricator should be installed and oil supply properly regulated. Your ARO Distributor can furnish the correct combination air line

filter and oiler. Some units can service up to three tools simultaneously. As a further precaution, put a few drops of light oil in air

inlet of tool before attaching tool to air line for the first time.

RECOMMENDED LUBRICANTS: Spindle Oil 29665 (I qt. container) for oiler and air inlet.

FILTERED AND OILED AIR will allow the tool to operate more efficiently and yield a longer life to operating parts and

mechanisms. A line filter capable of filtering particles larger than 50 microns should be used with a line oiler.

FILTER-REGULATOR-OILER combination (F-R-L) Model 28231-810 is recommended for use with this Air Tool. The capacity of

the individual Filter-Oiler is adequate to provide clean (40 micron), oiled and regulated air for the tool. AIR CONSUMPTION:

Approximately 25 SCFM.

RECOMMENDED HOSE SIZE: 5/16" nominal inside diameter.

oalJ\jMlNt PROPER AIR PRESSURES

AVK's power installation tools have been designed to operate at the listed "Dynamic" P. S.1.ratings at the air inlet of the tool. Even

though the in-line pressure gage may show the proper pressure, the use of long hoses, quick-disconnects and other couplers

between the gage and the tool can adversely affect the tool's performance. A simple test, so you may correlate our required P. S.1.

setting with your set-up is:

1. Connect a 1/4" short pipe nipple into the tool's air inlet.

2. Screw a 1/4" pipe tee onto the pipe nipple and put an air gage into the upright leg of the pipe tee.

3. Connect the air supply to the pipe tee using the actual hose, fittings, couplers or connectors that will be used.

4. Now, check the P.S.1.on the test gage at the air tool inlet with the tool running. Adjust, as necessary, the air pressure regulator

so that the P.S.1.required is shown on the test gage. Note the reading on the in-line pressure gage. It will probably read a higher

P. S.1.than the gage at the tool. The figure on the in-line gage is the "Adjusted Dynamic P.S.I." Use this figure when using the tool

in that location with that hose set-up.

5. Remove tee, nipple and gage, connect air supply directly to tool and begin production.

Test dynamic air pressure readings at the

location where the tool is to be operated*

(Instructions, fig. 3)

2

Adjust the in-line air pressure regulator so that dynamic

pressure is in accordance with AVK's power tool specs

at the air tool inlet.

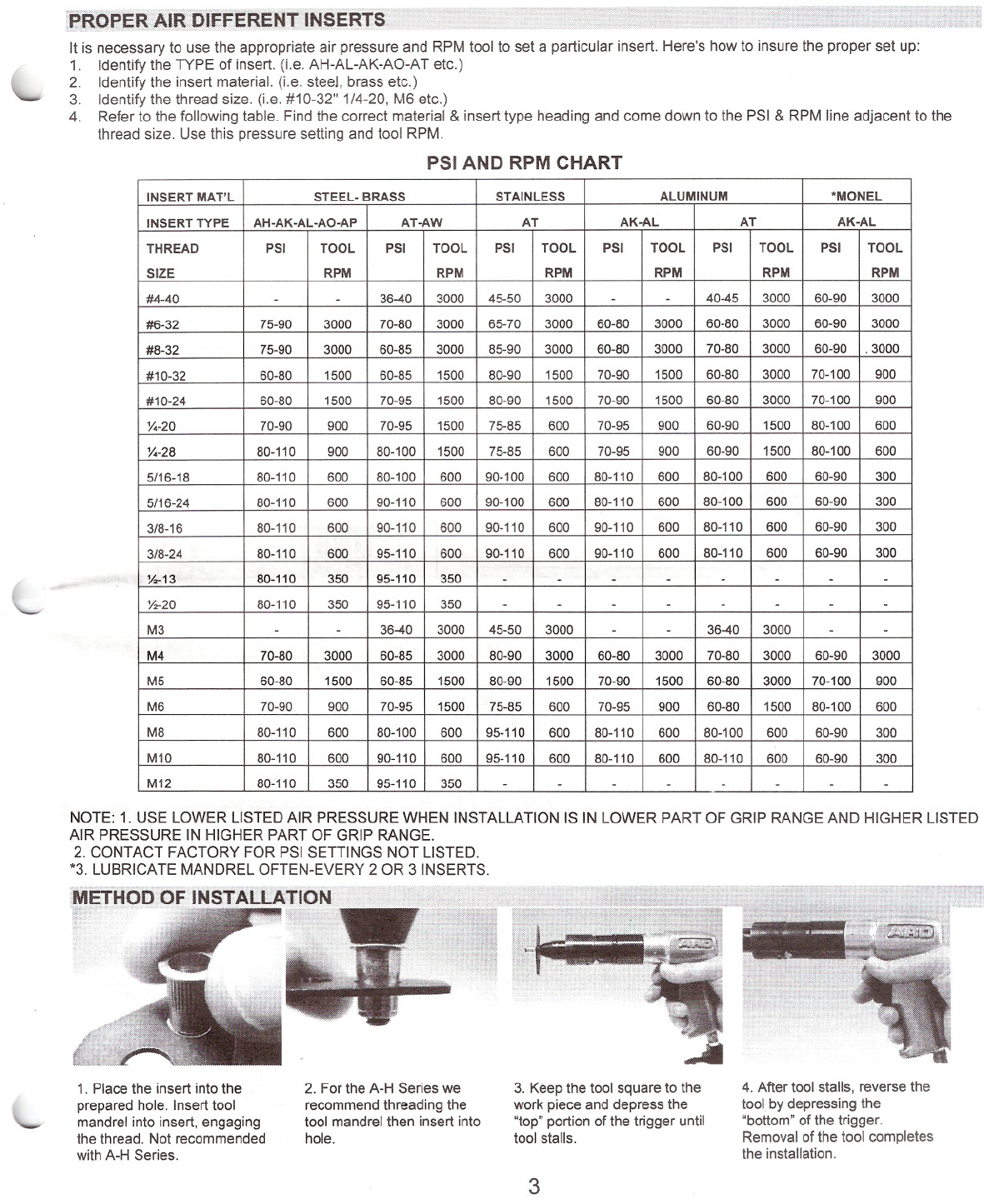

It is necessary to use the appropriate air pressure and RPM tool to set a particular insert. Here's how to insure the proper set up:

1. Identify the TYPE of insert. (i.e. AH-AL-AK-AO-AT etc.)

2. Identify the insert material. (i.e. steel, brass etc.)

3. Identify the thread size. (i.e. #10-32" 1/4-20, M6 etc.)

4. Refer to the following table. Find the correct material & insert type heading and come down to the PSI & RPM line adjacent to the

thread size. Use this pressure setting and tool RPM.

PSI AND RPM CHART

INSERT MAT'L STEEL- BRASSSTAINLESSALUMINUM

'MONEL

INSERT TYPE

AH-AK-AL-AO-APAT-AWATAK-ALATAK-AL

THREAD

PSITOOLPSITOOLPSITOOLPSITOOLPSITOOLPSITOOL

SIZE

RPMRPMRPMRPMRPM

RPM

#4-40

-

-

36-40

300045-503000

-

-

40-45

300060-903000

#6-32

75-90

300070-80300065-70300060-803000

60-80

300060-90

3000

#8-32

75-90300060-85

3000

85-903000

60-80

300070-80

300060-90

.3000

#10-32

60-80150060-85

1500

80-90150070-90150060-80300070-100900

#10-24

60-80150070-95150080-90150070-90150060-80300070-100900

X,-20

70-9090070-95150075-8560070-9590060-90150080-100600

X,-28

80-11090080-100150075-8560070-9590060-90150080-100600

5/16-18

80-11060080-10060090-10060080-11060080-100

60060-90

300

5/16-24

80-11060090-11060090-10060080-11060080-10060060-90

300

3/8-16

80-11060090-11060090-11060090-11060080-11060060-90300

3/8-24

80-11060095-11060090-11060090-11060080-11060060-90300

%-13

80-11035095-110350

-

-

------

%-20

80-11035095-110350

-

-

------

M3

-

-

36-40

3000

45-50

3000

-

-

36-40

3000

-

-

M4

70-80300060-85300080-90

3000

60-80300070-80300060-903000

M5

60-80150060-85150080-90

1500

70-90150060-80300070-100900

M6

70-9090070-95150075-8560070-9590060-80150080-100600

M8

80-11060080-10060095-110

600

80-11060080-10060060-90

300

M10

80-11060090-11060095-110

600

80-11060080-11060060-90300

M12

80-11035095-110350

-

-

-

----

-

NOTE: 1. USE LOWER LISTED AI R PRESSURE WHEN INSTALLATION IS IN LOWER PART OF GRIP RANGE AND HIGHER LISTED

AIR PRESSURE IN HIGHER PART OF GRIP RANGE.

2. CONTACT FACTORY FOR PSI SETTINGS NOT LISTED.

*3. LUBRICATE MANDREL OFTEN-EVERY 2 OR 3 INSERTS.

1. Place the insert into the

prepared hole. Insert tool

mandrel into insert, engaging

the thread. Not recommended

with A-H Series.

2. For the A-H Series we

recommend threading the

tool mandrel then insert into

hole.

3. Keep the tool square to the

work piece and depress the

"top" portion of the trigger until

tool stalls.

3

4. After tool stalls, reverse the

tool by depressing the

"bottom" of the trigger.

Removal of the tool completes

the installation.

Power ranges have been carefully selected to assure proper insert

installation. One RPM tool may be used to set various thread size

inserts as shown in the PSI and RPM chart. Be sure to match the RPM of

the tool to the insert thread size, and insert material.

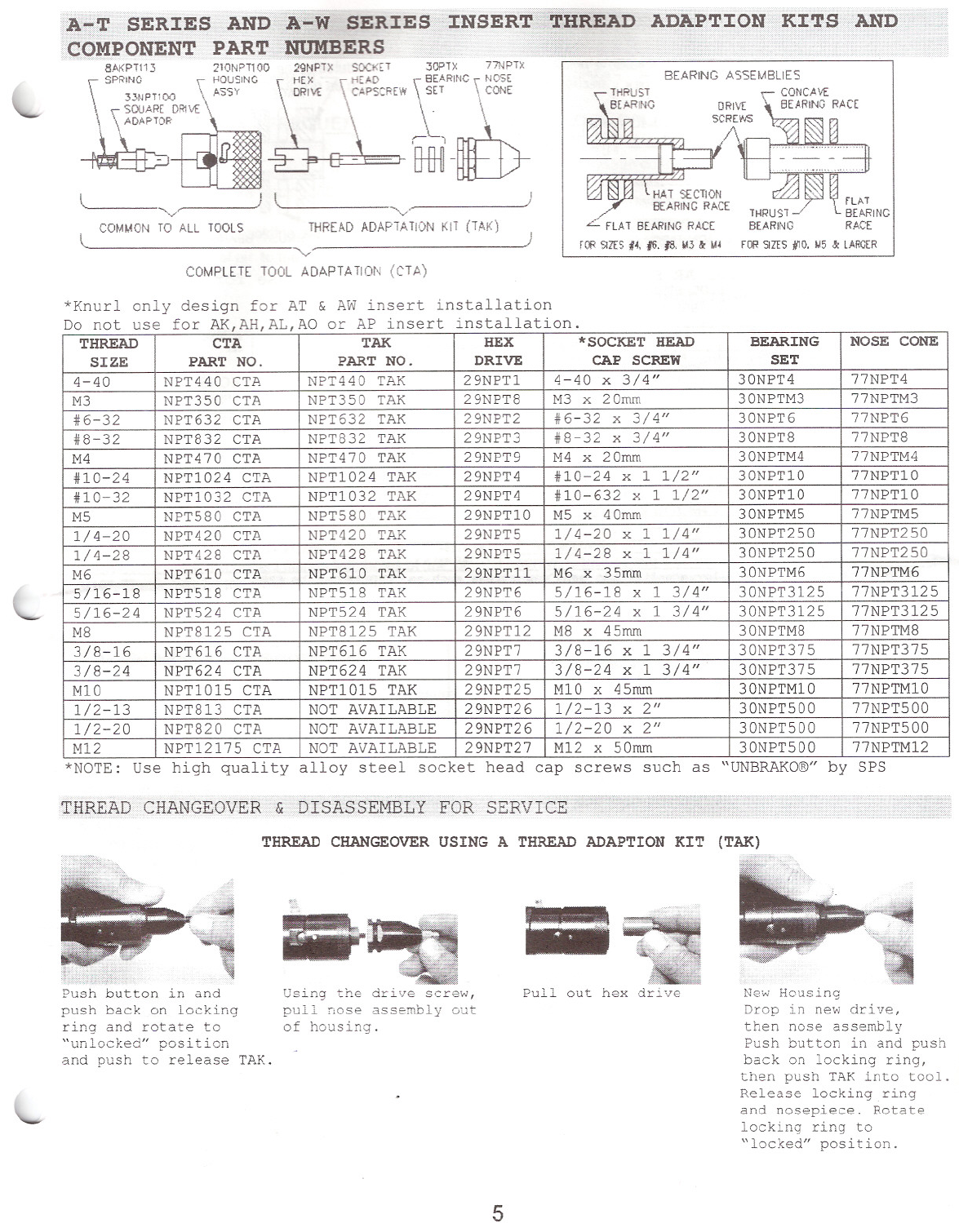

Complete tool adaption kit (CTA) is that portion of the tool that is

screwed onto the air motor to make a AVK insert tool. (Left hand thread)

Thread adaption kit, (TAK) is the portion of the CTA that is disengaged

by activation of the "quick release mechanism". Note the following

illustrations.

A~H,'A-K,A-L, A-O AND A-P SERIES INSERT THREAD ADAPTION KITS

AND COMPON.E.NT Pl2:Rrr~UI-1:BERS •

.{:'>:':. <:.'-, _;"''''' "" """" ,,,. •••• _:."","", :.:'''.'.''''''~''':. ;«_,co..,. ." .. :.:::;:;;;; ..... ,,;: .. ,,~ .. ~.,.,

fOR SIZES 16. 18 ~ "' .•

I

J

I

,I

socl<n 32PT)<

HE/o.D '\ ~~ING

"fSCR£W{

f )

Jill

CO~PLETE

l )l

----.'v~----- ------.'v ....

COMMON TO ALL TOOLS THREAD ADAPTATION KIT (T .AI<)

l-----------''v~

TOOL ADAPTATION (CTA~

*Nozzle design for AH,AK,AL,AO and AP Series Insert

Installation - Do not use for AT,AW or RN Series insert installation.

THREAD CTA

TAK

HEX*SOCKET HEAD

BEARING

NOSE CONE

SIZE PART NO.PART NO.DRIVE

CAP SCREWSET

#6-32 AKPT632 CTAAKPT632 TAK29NPT22

#6-32 x 1 1/2"

32PTI

77AKPT6

#8-32 AKPT832 CTAAKPT832 TAK

29NPT23

#8-32 x 1 1/2"

32PT277AKPT8

M4xO.7 AKPT470 CTAAKPT470 TAK

29NPT24M4 x 40mm 32PT3

77AKPT470

#10-24 AKPTl024 CTAAKPTI024 TAK29NPT4

#10-24 x 1 3/4"

32PT4

77AKPTI0

#10-32 AKPTl032 CTAAKPTl032 TAK29NPT4

#10-632 x 1 3/4"

32PT4

77AKPTlO

M5xO.8 AKPT580 CTA

AKPT580 TAK

29NPTlO

M5 x 45mm 32PT477AKPT580

1/4-20 AKPT420 CTA

AKPT420 TAK29NPT5

1/4-20 x 1 1/2"

32PT5

77AKPT250

1/4-28 AKPT428 CTA

AKPT428 TAK

29NPT5

1/4-28 x 1 1/2"

32PT5

77AKPT250

M6xl.0 AKPT610 CTA

AKPT610 TAK29NPTll

M6 x 40mm 32PT677AKPT610

5/16-18 AKPT518 CTA

AKPT518 TAK

29NPT6

5/16-18 x 2"

32PT777AKPT3125

5/16-24

AKPT524 CTAAKPT524 TAK

29NPT6

5/16-24 x 2"

32PT7

77AKPT3125

M8xl. 25 AKPT8125 CTA

AKPT8125 TAK29NPT12M8 x 50mm 32PT777AKPT8125

3/8-16

AKPT616 CTAAKPT616 TAK29NPT7

3/8-16 x 2"

32PT877AKPT375

3/8-24

AKPT624 CTAAKPT624 TAK29NPT7

3/8-24 x 2"

32PT8

77AKPT375

MI0xl. 5

AKPTl015 CTAAKPTl015 TAK29NPT25MI0 x 50mm 32PTI077AKPT1015

1/2-13

AKPT813 CTA

NOT AVAILABLE29NPT26

1/2-13 x 2500

30NPT50077AKPT500

1/2-20 AKPT820 CTA

NOT AVAILABLE29NPT26

1/2-20 x 2500

30NPT50077AKPT500

I-...

M12xl.75

AKPT12175 CTANOT AVAILABLE29NPT27M12 x 60mm 30NPT500

77AKPTM12 -U'

~

*NOTE: Use high quality alloy steel socket head cap screws such as "UNBRAKO®" by SPS

4

BEARING AS5EMBLIES

CONCAVE

BE••••RING RAc[

HAT SECTION

BEARING RACE

/'

L- FLAT BEARING RACE

ref: SIltS 14, fli. 18, it} &: 1.14

SOCKET JOPTX 7~iPTX

HEAD ~EARING \' NOSE

CAPSCREW SET \CONE

\

.\

\tW-ED-

SERIES

ERS

COMMON TO ALL TOOLS

l _ ,,'

COMPLETE TOOL ADAPT ATION (CT A)

SERIES.? AN

~QNJ?ONENT PAR

8AKPT113 21QNPT100

SPRING '\ HOUSING

33NPT100Gl"'5'3Y ....

.- SOUAR[ DRiVE

\, ADAPTOR

l -..../ Jl~-------.v.------)

THREAD ADAPTATION KIT (TAl<)

*Knurl only design for AT & AW insert installation

Do not use for AK,AH,AL,AO or AP insert installation.

THREAD CTATAKHEX

*SOCKET HEAD

BEARINGNOSE CONE

SIZE

PART NO.PART NO.DRIVECAP SCREWSET

4-40

NPT440 CTANPT440 TAK29NPT1

4-40 x 3/4"30NPT4

77NPT4

M3

NPT350 CTANPT350 TAK29NPTSM3 x 20mm 30NPTM377NPTM3

#6-32

NPT632 CTANPT632 TAK29NPT2

#6-32 x 3/4"30NPT6

77NPT6

#8-32

NPT832 CTANPTS32 TAK29NPT3

#S-32 x 3/4"

30NPTS

77NPTS

M4

NPT470 CTANPT470 TAK29NPT9M4 x 20mm 30NPTM4

77NPTM4

#10-24

NPT1024 CTANPTl024 TAK29NPT4

#10-24 x 1 1/2"30NPT10

77NPT10

#10-32

NPT1032 CTANPT1032 TAK29NPT4

#10-632 x 1 1/2"

30NPT10

77NPT10

M5

NPT5S0 CTANPT5S0 TAK29NPT10M5 x 40mm 30NPTM577NPTM5

1/4-20

NPT420 CTANPT420 TAK29NPT5

1/4-20 x 1 1/4"

30NPT250

77NPT250

1/4-2S

NPT42S CTANPT42S TAK29NPT5

1/4-2S x 1 1/4"

30NPT25077NPT250

M6

NPT610 CTANPT610 TAK29NPTllM6 x 35mm 30NPTM677NPTM6

5/16-1S

NPT51S CTANPT51S TAK29NPT6

5/16-1S x 1 3/4"

30NPT3125

77NPT3125

5/16-24

NPT524 CTANPT524 TAK29NPT6

5/16-24 x 1 3/4"30NPT3125

77NPT3125

MS

NPTS125 CTANPTS125 TAK29NPT12MS x 45mm 30NPTMS

77NPTMS

3/S-16

NPT616 CTA

NPT616 TAK29NPT7

3/8-16 x 1 3/4"

30NPT375

77NPT375

3/8-24

NPT624 CTANPT624 TAK29NPT7

3/S-24 x 1 3/4"

30NPT375

77NPT375

M10

NPT1015 CTA

NPT1015 TAK29NPT25M10 x 45mm30NPTM1077NPTM10

1/2-13

NPTS13 CTANOT AVAILABLE

29NPT26

1/2-13 x 2"

30NPT50077NPT500

1/2-20

NPTS20 CTA

NOT AVAILABLE

29NPT26

1/2-20 x 2"

30NPT500

77NPT500

M12 NPT12175 CTANOT AVAILABLE29NPT27M12 x 50mm30NPT50077NPTM12

*NOTE: Use high quality alloy steel socket head cap screws such as "UNBRAKO®" by SPS

THREAD CHANGEOVER

THREAD CHANGEOVER USING A THREAD ADAPTION KIT (TAK)

=

Push button in and

push back on locking

ring and rotate to

"unlocked" position

and push to release TAK.

Using the drive screw,

pull nose assembly out

of housing.

Pullout hex drive New Housing

Drop in new drive,

then nose assembly

Push button in and push

back on locking ring,

then push TAK into tool.

Release locking ring

and nosepiece. Rotate

locking ring to

"locked" position.

5

COMPl.ETE TOOL ADAPTATION (CTA)

~.EARINi

RACE

, 0

8~...==..~..3

..............................

~~n~

~ST BEARING

)

'-/

THREAD ADAP'A TION KIT (TAK)

)~

210NP11QO 29NPTX SOCKET 32PTX 77ARPTX

HOUSING '\ HEX \" HEAD __ BEARING \ NOSE

"" ~~~ \"'"'~ \ ' •.•ET \ CONE

\ ,L,~- -- HH1lJ}

'-/

COMMON TO ALL TOOLS

8AKPT113

\ SPRI,\G -

33N°T100

, __ SOUARE DRIVE

~:C"

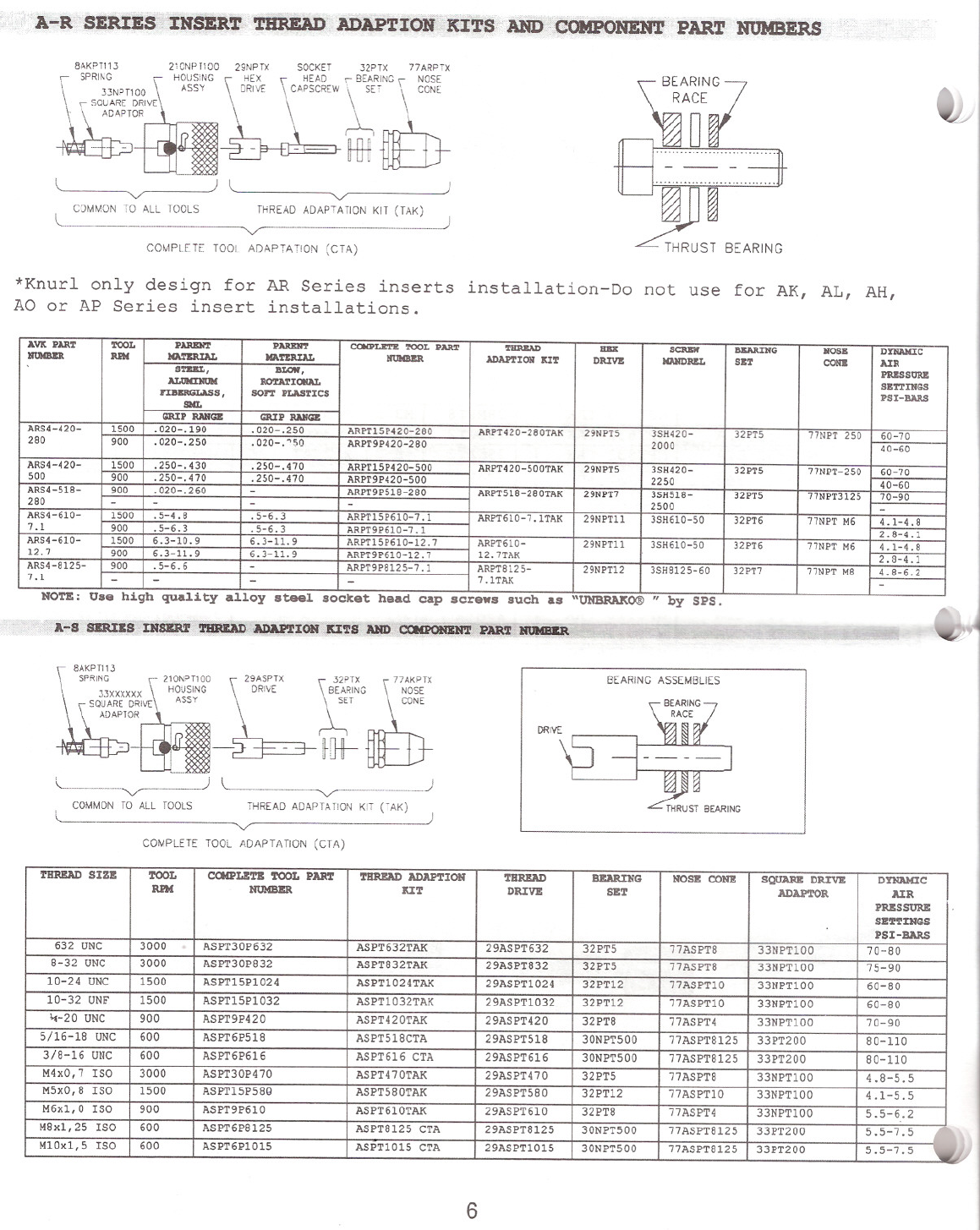

*Knurl only design for AR Series inserts installation-Do not use for AK, AL, AH,

AO or AP Series insert installations.

AVlt PART TOOLPAREN'l'PARENT

cacPLETE TOOL PARTTHREAD

IIBXSCl\IlW

BKARING1I0SB

DmAKIC

NOIIIlZR IU'MlCATBIUAL

MA'l'ZIUAL

NOIIIlZRADAPTIOII ItITDIUVB

IIAIlDIUILSIlTCONII

AIR

STEEL, BLOW, PRBSSORBALtJNDIUM RO'rATIOHAL SBTTINGS

I'IllBRGLASS , SOFT PLASTICS PSI-BARS

SML GRIP RANGE GRIP RANGE

ARS4-420- 1500.020- .190 .020-.250

ARPT15P420-280ARPT420-280TAK

29NPT5

3SH420-

32PT5

77NPT 250

60-70

280 900

.020-.250 .020-. "50

ARPT9P420-280 2000

40-60

ARS4-420-

1500.250-.430 .250-.470

ARPT15P420-500ARPT420-500TAK

29NPT53SH420-

32PT577NPT-25060-70

500 900.250-.470 .250-.470

ARPT9P420-500 2250

40-60

ARS4-518- 900

.020-.260 -ARPT9P518-280

ARPT518-280TAK

29NPT73SH518-32PT5

77NPT3125

70-90

280 -

--

-2500

-

ARS4-610- 1500.5-4.8 .5-6.3

ARPT15P610-7.1

ARPT610-7.1TAK

29NPTll3SH610-5032PT677NPT M64.1-4.8

7.1 900

.5-6.3 .5-6.3

ARPT9P610-7.1 2.8-4.1

ARS4-610- 1500

6.3-10.9 6.3-11.9

ARPT15P610-12.7

ARPT610-29NPTl13SH610-5032PT677NPT M64.1-4.8

12.7 900

6.3-11. 9 6.3-11. 9ARPT9P610-12.7

12.7TAK 2.8-4.1

ARS4-8125- 900

.5-6.6 -ARPT9P8125-7.1

ARPT8125-29NPT12

3SH8125-60

32PT7

77NPT M8

4.8-6.2

7.1 -

--- 7.1TAK -

NOTE: Use high qua1ity a110y stee1 socket head cap screws such as uUNBRAXO® " by SPS.

BEARING ASSEMBLIES

~9ASPTX \.••.88.•..'[3E~~;~G '\77NA;;ETX

DRivE ~T \ CONE

- ·1Gt-~}

THREAD ADAPTA nON KIT (TAK)

'-/

COMPLETE TOOL ADAPTATION (CTA)

COMMON TO ALL TOOLS

632 UNC 3000

ASPT30P632 ASPT632TAK

29ASPT632

32PT577ASPTS

33NPT100

8-32 UNC 3000ASPT30PS32 ASPTS32TAK29ASPTS3232PT577ASPTS33NPT100

10-24 UNC

1500ASPTl5P1024 ASPT1024TAK29ASPT1024

32PT12

77ASPTlO33NPT100

10-32 UNF

1500

ASPTl5P1032 ASPT1032TAK29ASPTl03232PT1277ASPT1033NPT100

4-20 UNC

900ASPT9P420 ASPT420TAK

29ASPT420

32PTS

77ASPT433NPT100

5/16-1S UNC 600ASPT6p51S ASPT51SCTA

29ASPT51S30NPT50077ASPTS125

33PT200

3/S-16 UNC

600

ASPT6P616 ASPT616 CTA29ASPT61630NPT50077ASPTS12533PT200

M4xO,7 ISO

3000ASPT30P470 ASPT470TAK29ASPT47032PT577ASPT833NPT100

M5xO,S ISO

1500ASPT15P5SQ ASPT5S0TAK

29ASPT5S0

32PT1277ASPT1033NPT100

M6x1,0 ISO

900

ASPT9P610 ASPT610TAK29ASPT610

32PTS77ASPT4

33NPT100

MSx1,25 ISO 600ASPT6PS125 ASPTS125 CTA29ASPTS12530NPT50077ASPTS125

33PT200

M10x1,5 ISO

600ASPT6P1015 ASPT1015 CTA

29ASPT101530NPT50077ASPTS12533PT200

6

THREAD SIZE rooL

RPM C~LETI!i TOOL PART

NtJMBER TIIREAJ) ADAPTION

lUT THREAD

DRIVI!: BEARING

SET NOSB CONE SQUARB D1UVI!:

ADAPTOR DYNAMIC

AIR

PRESSURE

SETTINGS

PSI-BARS

70-S0

75-90

60-S0

60-S0

70-90

S0-110

SO-110

4.S-5.5

4.1-5.5

5.5-6.2

5.5-7.5

5.5-7.5

·TRouBlEl~lIpoTING

Below are some guidelines for solutions to common setting and tooling problems. By following these steps you should be

able to get back into production as quickly as possible if a problem arises:

SCREWS BREAK FREQUENTLY

1. Too much air line pressure. Check the air pressure specs

for the thread size you are placing. Adjust downward

accordingly.

2. Make sure operator is holding the tool at a 90° angle to

the adequate supply of air to the tool.

TOOL STALLS BEFORE FULLY

PLACING THE INSERT

1. Be sure there is a bearing assembly in the tool. Check to

be sure it is not worn out, and that it is assembled correctly.

(see pg. 4 or 5). Clean in solvent, blow dry and lubricate with

recommended grease. (See tool maintenance section of this

manual.)

2. Check for quick disconnect fittings with holes of 1/4" or

3/16". These may be too small to allow the necessary

VOLUME into the tool. This is especially critical with the 5/16,

3/8 and %thread size.

3. Be sure the hose 1.0. is 5/16".

4. Not enough air line pressure. Check the air pressure

specs for the thread size you are placing. Adjust upward

accord ingly.

5. Check the condition of the drive screw. Replace, if worn

using high quality socket head cap screws.

6. Check to see if other air tools are being used that are

starving the insert installation tool.

TOOL WILL NOT START/RUN

1. With air system connected, quickly change from forward to

reverse several times.

2. Check your air line and air pressure to assure there is an

work piece, and not "tilting" it over to one side.

3. Remove the complete tool adaptation kit. Manually rotate

rotate the square drive shaft. Connect air to tool and depress

trigger.

4. Evaluate airline set-up portion of this manual.

5. If there is an air motor failure, follow instructions in

maintenance section of this manual.

AIR MOTOR RUNS,

PLACING SCREW DOESN'T

Make sure hex drive is engaged into the socket head cap

screw. Check to see if screw is broken or if the head is rounded

out. Check also, if the hex drive itself has been rounded off.

Replace defective parts as may be required to assure proper

installation.

*CALL AVK FOR ADDITIONAL TROUBLE

SHOOTING SUGGESTIONS

I. Inadequate compressor capacity.

4. Be sure hose and quick disconnect fittings have 5/16" 1.0.

2. Improper pipe sizes (1.0. too restrictive).

3. Restrictions caused by fittings with 1.0.'s too small. See

Note 3 above.

If recommended pressures cannot be obtained, the supply system should be checked. Some things to look for are:

5. Shut-off valves. It is best to use stop cock type, which

lessen restrictions.

6. Improper coupler and quick disconnect. Use only those with

good flow characteristics and assure that they mate

correctly.

7. Filter-regulator-lubricator should be compatible, properly

sized and maintained.

8. Clogged filter.

*CALL AVK FOR ADDITIONAL TROUBLE SHOOTING SUGGESTIONS

7

TOOL MAINTENANCE

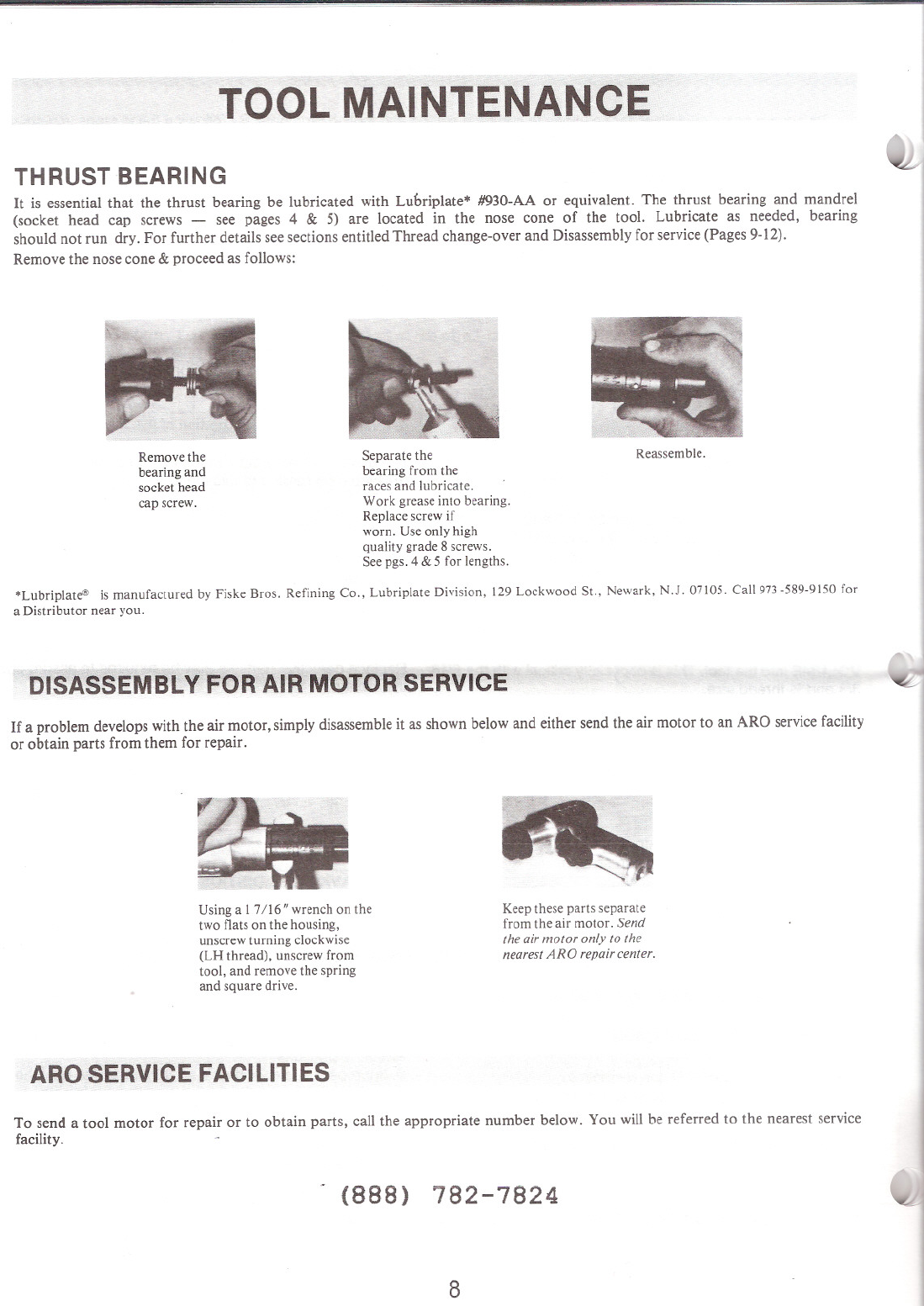

THRUST BEARING

It is essential that the thrust bearing be lubricated with Luoriplate* #930-AA or equivalent. The thrust bearing and mandrel

(socket head cap screws - see pages 4 &5) are located in the nose cone of the tool. Lubricate as needed, bearing

should not run dry. For further details see sections entitled Thread change-over and Disassembly for service (Pages 9-12).

Remove the nose cone &proceed as follows:

Remove the

bearing and

socket head

cap screw.

Separate the

bearing from the

races and lubricate.

Work grease into bearing.

Replace screw if

worn. Use only high

quality grade 8 screws.

See pgs. 4 &5 for lengths.

Reassemble.

*Lubriplate® is manufactured by Fiske Bros. Refining Co., Lubriplate Division, 129 Lockwood St., Newark, N.J. 07105. Call 973 -589-9150 for

a Distributor near you.

DISASSEMBLY FOR AIR MOTOR SERVICE

If a problem develops with the air motor, simply disassemble it as shown below and either send the air motor to an ARO service facility

or obtain parts from them for repair.

U sing a 1 7/16" wrench on the

two flats on the housing,

unscrew turning clockwise

(LH thread), unscrew from

tool, and remove the spring

and square drive.

ARO SERVICE FACILITIES

Keep these parts separate

from the air motor. Send

the air motor only to the

nearest ARO repair center.

To send a tool motor for repair or to obtain parts, call the appropriate number below. You will be referred to the nearest service

facility.

(888) 782-7824

8

PREVENTIVE MA~~TENANCE

HANDLE WITH ORDINARY CARE. A high proportion of tool repairs can be traced to careless handling. In spite of their

inherent strength, air tools should not be used as hammers or levers, nor should they be deliberately dropped or dragged along the

floor.

LUBRICA nON OF GEARED TOOLS. Certain types of air tools contain gearing which should be lubricated regularly with gear

grease. Most of these tools have external hydraulic fittings which can be serviced by ARO's Grease Gun #7464-1. Grease 33153 (5

lb. can) for gears and bearings; "0"Ring Lubricant 36460(4oz. tube) for lubrication and installation of "0"Rings.

CAUTION: An excessive amount of lubricant in a tbol will affect the speed and power. Each set of planetary gearing should

contain approximately 1/8 ounce of grease.

FLUSH TOOL with a solution of three parts cleaning solvent and one part light oil after each 40 hours of operation. After

flushing, apply a small amount of Spindle Oil in air inlet and run free for one minute to insure proper lubrication.

IF LINE OILER is not used, apply a small amount of Spindle Oil in air inlet of tool and run free for one minute to insure proper

lubrication; after each 8 hours of operation.

LUBRICATE DRIVE SCREW. In some applications it may be advisable to dip the first one or two threads of the mandrel into a

light oil after several installations to minimize wear.

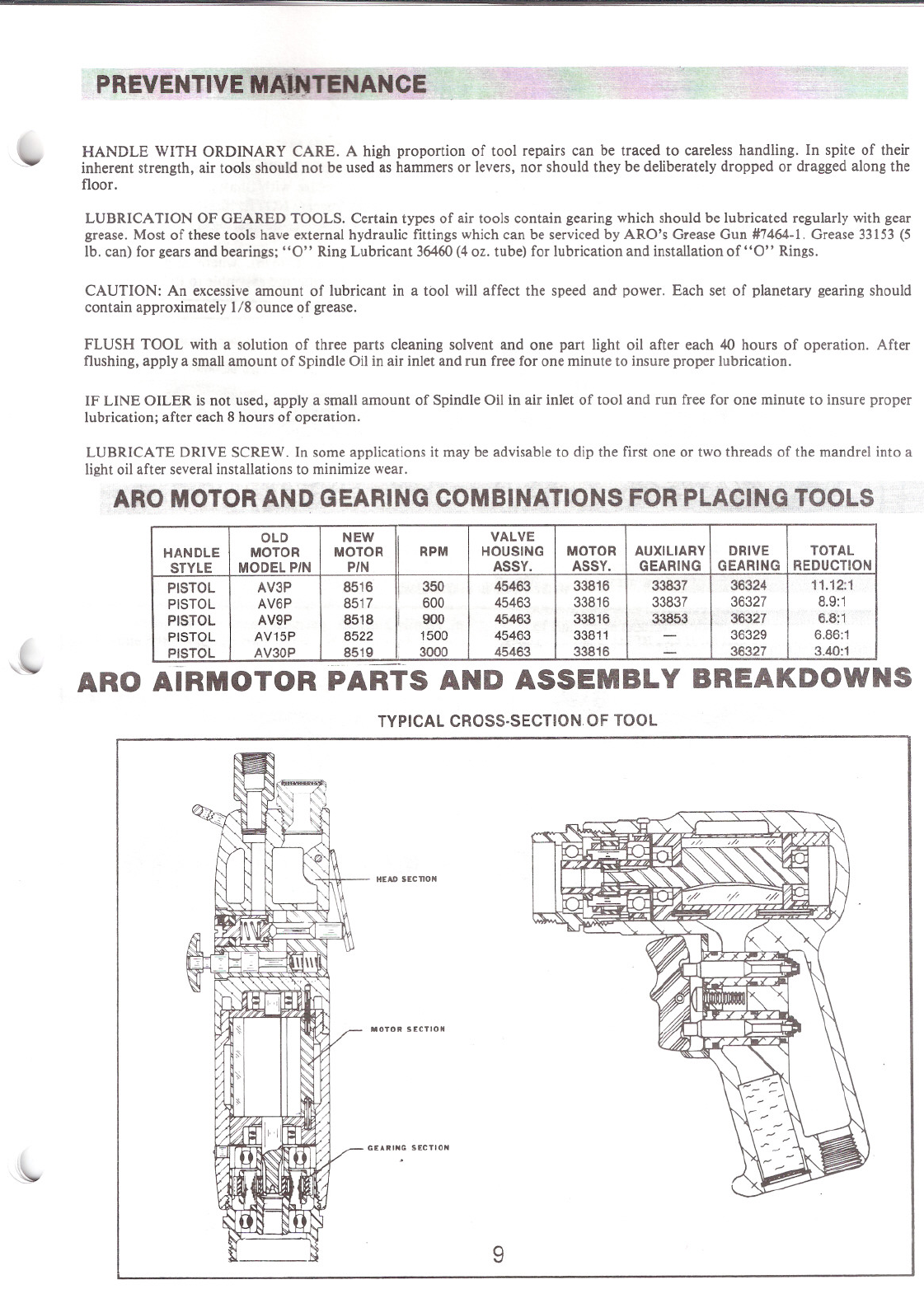

ARO MOTOR AND GEARING COMBINATIONS FOR PLACING TOOLS

OLD

NEW VALVE

HANDLE MOTOR

MOTOR

RPMHOUSINGMOTORAUXILIARYDRIVETOTAL

STYLE MODEL PIN

PIN ASSY.ASSY.

GEARING

GEARINGREDUCTION

PISTOL

AV3P85163504546333816338373632411.12:1

PISTOL AV6P8517600454633381633837363278.9:1

PISTOL

AV9P8518

i

900 45463338163385336327

6.8:1

IPISTOL AV15P

8522

1500

4546333811

-

36329

6.86:1

PISTOL AV30P851930004546333816

-

36327

3.40:1

ARO AIRMOTOR PARTS AND ASSEMBLY BREAKDOWNS

TYPICAL CROSS·SECTION OF TOOL

HEAD SECTION

MOTOR SECTION

GEARING SECTION

9

GEARING SECTION

DRIVE GEARING

DISASSEMBL Y

a. Remove Spindle and components from Ring Gear.

b. To remove Gears from Spindle, remove Bearing,

Spacer and Shafts.

REASSEMBLY

NOTE: Pack bearings and lubricate gears liberally with

33153 grease or equivalent upon assembly. Gearing

assembly should contain approx. 1/8 Ol. grease.

32325 BEllRING\

36325 RING GEAR -, \

30901 [)RIVE GEAR ~

(9INT-17EXT.TEETH) . ~

32325 BEARING\ ~

36325 RING GEAR -, \ . ~ "7...,

\ a~}

~

33691 SPACER

3OB99 GEAR (21~i.

(12TEETHi ~

a. Assemble Spacer (33691) or (33693) and Gears to

Spindle and secure with Shafts, aligning notch in

Shafts with Spacer. NOTE: Shafts (33686) contain

fifteen (15) loose Needle Bearings (33458) per shaft.

b. Assemble Spacer (37676), where applicable, and

Bearings to Spindle and assemble to Ring Gear.

- 32325 BEARING

36324 GEARING ASS'Y

5.56'1

,

~33436 SHAFT(2l

,37676 !;Pjl,CER (32325 BEARING

I~

36327 GEARING ASS'Y

3.4 I

I

\ ~ 33686 SKAFT(21'--()It:::l (INCLUDES LOOSE NEEDLE BEARINGS

] ~ PE R SHAFT)

REPLACE WITH 33686 KIT

36325 RING GEAR

32325 BEARING~ \\\.

'33438 GEAR (2)

(17 TEETH)

~~-A

r-.

I!32325 BEARING

./

.~)1--(0-36329 GEARING ASS"

J. .6660 \ \~VJA)6.861~ ~

10

AUXILIARY GEARING

Y147-7 RETAINING RING-,

{37676 SPACER

, ;- 32325 BEARING

/32325 BEARING

•~"

/ ~ /'0, \

\, \ '- ~ ;' 33837 GEARING ASS'Y

~ ~561

MOTOR SECTION

DISASSEMBL Y aligning air inlet holes of Cylinder with air inlet slots

a. Remove Motor from Housing. Grasp Cylinder in of End Plate and assemble Blades into Rotor Slots.

one hand and tap splined end of Rotor with a non- d. Assemble front End Plate (31602) to Rotor and Cylin-

metallic hammer; motor will come apart. der, aligning Roll Pin in Cylinder with hole in End

REASSEMBLY Plate.

a. Pack bearings with grease (33153), or equivalent, e. Insure Rotor does not bind (if Rotor binds, lightly

and coat I.D. of cylinder with spindle oil upon tap splined end with a non-metallic hammer to

assembly. loosen) and assemble motor to housing with Locating

b. Assemble Bearings into End Plates and assemble Pin (32814) and Porting Block (45471).

rear End Plate (3160 1)to Rotor. f. Assemble Spacer (32310), Spacer (32305) and gear-

c, Assemble Cylinder over Rotor to rear End Plate ing to tool.

33816

----

MOTOR

ASSEMBLY

33811

MOTOR

ASSEMBLY

Y65-7 BEARING

END PLATE

Y65-7 BEARING

~65-15 BEARING

,31602 END PLATE

36806 HOUSING *r

(LEVER THROTTLE ONLY) I

JI"<TO' GRI' ON' VJ

';

SPACER 32310 *"

SPACER 32305 *" ' -

*NOT INCLUJED IN MOTOR ASS'Y. ~

flNCLUDED WITH CYLINDER ~ fROLL PIN Y178-20

f ROLL PIN Y178'24

LOCATING PIN 32814 *

(PISTOL GRI P ONLY)

11

~ 42911 SCREEN (2}A

~ Yl47-68 "ET tr))

". AINING RING-----/~

M30

32

/~

; ,

..

\ i

"~~---_\;

==::t}o

45462 HOUSING ASS'y,

INClUOES 35967 GREASE FITTING.

NOr SHOW N

ings (45465).

b Assemble "0" rin.9 (Y325-7) to valve assembly (47880)

c Lubricate plunger (47879) and valve assembly (47880) with

ARO 29665 spindle all

d. Assemble springs (48806-1) to valve assembly (47880).

e Assemble plungers (47879) and valve assemblies (47880) to

bushings (45465) and assemble bushings to housing, align-

ing flats of bushings with flats of shroud

f. Assemble shroud (45468) to housing, securing with screw

(Y222-] 56-C)

g Assemble trigger to Shroud, secUring With roll pm (Y178-25)

h' Assemble muffler (45474) and screens (42911) to hOUSing,

securing with retaining ring (Y147-68)

DISASSEMBl Y

--------- HEAD SECTION ---------

45474

~

47880 VALVE ASSEM8l Y (2)

f81 YJ25-7 "0" RING (2)

.45471 PORTING 9LO;::K~

REASSEMBLY

45469 TRIGGER

a Remove roll pm (Y178-25), releasing trigger (45469)

b Remove screw (Y222-156-C), releasing shroud (45468)

cGrasp end of valveassembly (47880) and pull to remove valve

assembly and bushing (45465)

d Removeretaining f1ng(Y147-68). reieasing screens (42911) and

muffler (45474)

NOTE Whenever a port containing "0" rings has been removed

from loot, It is recommended the '0' rings be replaced Grease

all '0' rings before assembly.

c Assemble "0" rings (Y325-13, Y325-12 and Y325-11) to bush-

*NOT INCLUDED IN

45463 HOUSING aVALVES ASS'Y REVERSIBLE

45463 HOUSING 8 VALVES ASS'Y

PARTS MARKED THUS ~ ARE INCLUDED IN SERVICE KIT NO. 42122-2, SEE PAGE ]0,

12

HEAD SECTION

LEVER HEAD

DISASSEMBL Y

a. Remove Nut (36609) and Valve Parts may be re-

moved from Head.

b. To remove Reversing Valve (39207), remove Roll

Pin (YI78-7).

Motor assemblies for Lever Throttle tools: with

Motor Housing removed from Head; place Head in a

suitable holding device with the motor end in an up-

right position. Place Motor assembly on Head align-

ing Roll Pih (Y 178-24) with hole in Head. Slip Motor

Housing over Motor and secure to Head.

Assemble Spacers (32310), (32305) and Gearing to

tool.

REASSEMBLY

a. Assemble "0" Ring (YI25-2) to Valve Stem (3

and assemble to Head.

b. Assemble Spring (31131), Regulator (35642)

Seal (35675) to Head and secure with Nut (366C

*NOT INCLUDED IN HEAD ASS'Y

<~EETABLE)

"36992 ",VET 1o·

I

32863 BAIL*

~MUFFLER*

.~ I(([:j®)

~178-~ I ~.----' ,,::::\

ROLL PIN f

I39209 HOUSING130032 SPR ING 36602 VALVE STEM

~ Y125-2 "0"

~ RING

__ - 311" SP",NG

~ 35642 AIR REGULATOR

~~ 35675 SEAL

I /~- 73262 NYLON BALL

39210 HEAD ASS'Y .-- 36609 NUT

4/14/08

AVK INDUSTRIAL ,PRODUCTS

n!'t!J"'j

Ari;ri,;Company

25323 RYE CANYON ROAD • VALENCIA, CALIFORNIA 91355-1271

TELEPHONE: (661) 257-2329 FAX: (661) 257-8043

VISIT AVK'S WEBSITE AT AVKFASTENERS.COM CAT.NO 213M REV.l

This manual suits for next models

5

Table of contents

Other PCC Tools manuals