26

Table of Contents

1. General Introduction ……………………………………………………………………………………… 27

2. Abbreviations & Initials ………………………………………………………………………………… 28

3. Introduction ………………………………………………………………………………………………… 28

3.1 Specification …………………………………………………………………………………… 29

3.2 Front / Back panel …………………………………………………………………………… 30

4. Operation ………………………………………………………………………………………………… 32

4.1 Key Operation

…………………………………………………………………………………… 32

4.1.1 Power On …………………………………………………………………………… 32

4.1.2 PEAK …………………………………………………………………………………… 32

4.1.3 UNIT …………………………………………………………………………………… 32

4.1.4 ZERO …………………………………………………………………………………… 32

4.1.5 Back Light …………………………………………………………………………… 33

4.2 Menu/Function Select ……………………………………………………………………… 33

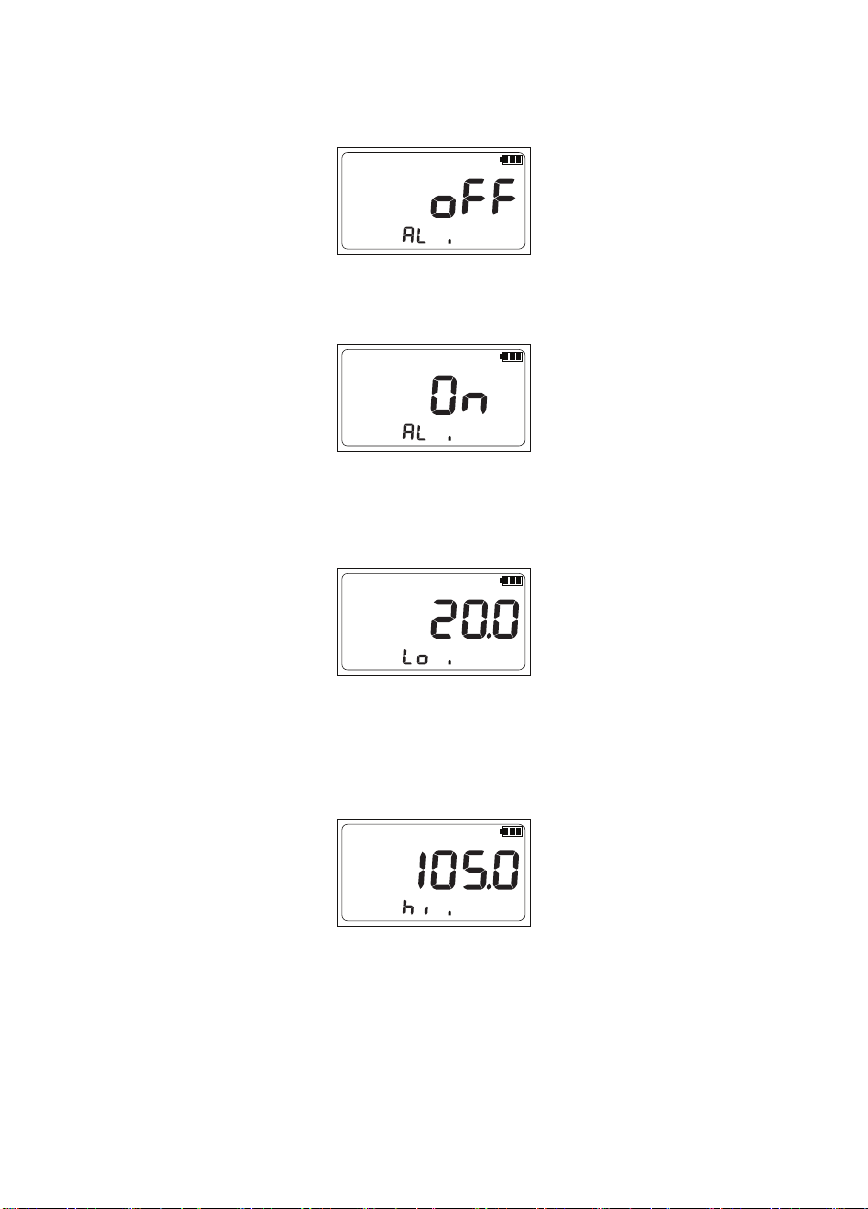

4.2.1 Alarm …………………………………………………………………………………… 33

4.2.2 Pressure Switch Test ……………………………………………………………… 35

4.2.3 Calibration …………………………………………………………………………… 38

4.2.4 Baud Rate …………………………………………………………………………… 39

4.2.5 RS232 Communication …………………………………………………………… 40

4.2.6 Auto Power Off …………………………………………………………………… 42

4.2.7 Data Logger ………………………………………………………………………… 43

4.2.8 Storage Data Clear ……………………………………………………………… 45

4.2.9 End …………………………………………………………………………………… 45

5. Maintenance Adjustments and Calibration ……………………………………………………… 46

5.1 Zero Adjustment ……………………………………………………………………………… 46

5.2 Pressure Calibration …………………………………………………………………………… 46

5.3 Analog Output Calibration ………………………………………………………………… 46

6. Troubleshooting ……………………………………………………………………………………………… 47

7. Appendix

…………………………………………………………………………………………………… 48

7.1. Warranty Statement

………………………………………………………………………… 48

7.2. Accessory

……………………………………………………………………………………… 48

7.3. Table of pressure unit conversion ……………………………………………………… 49