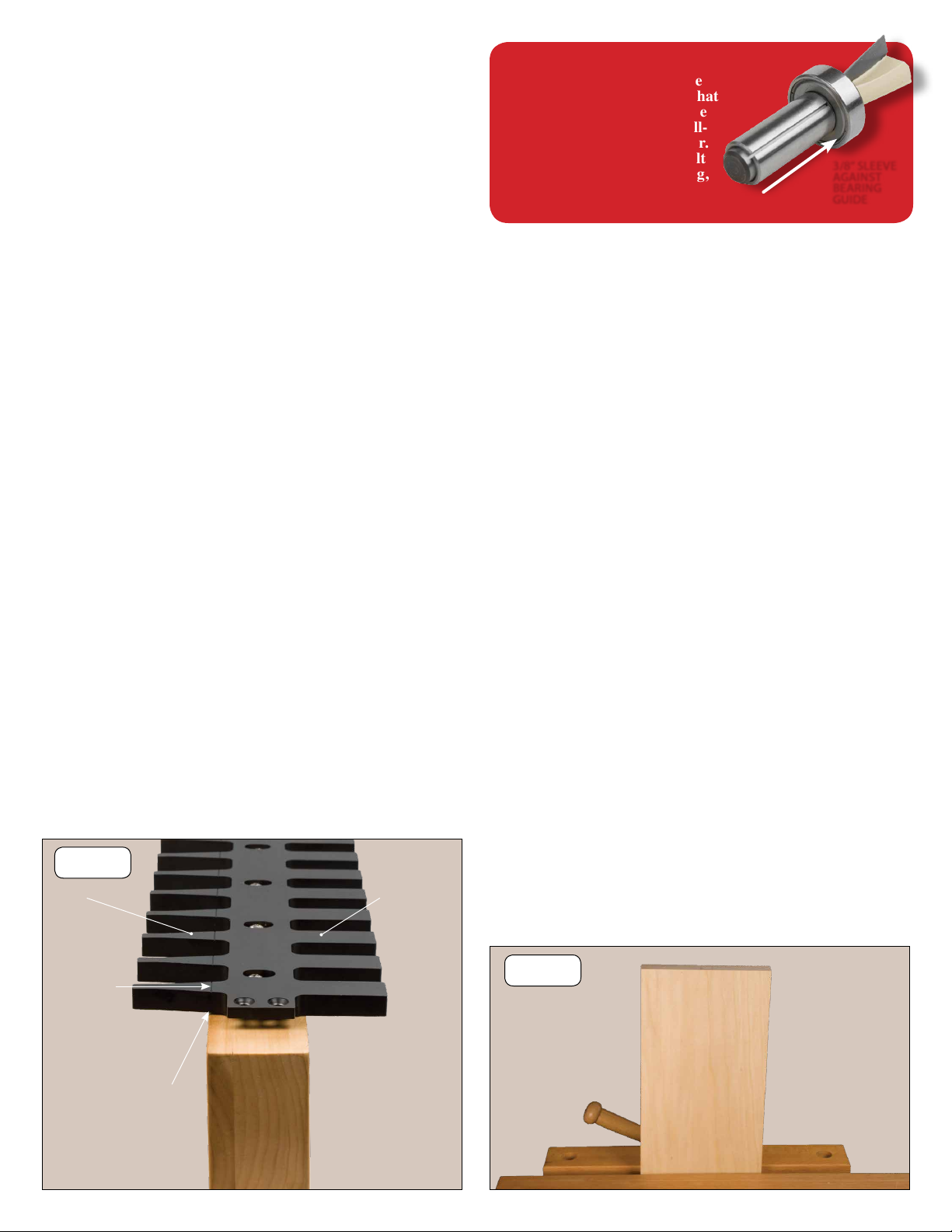

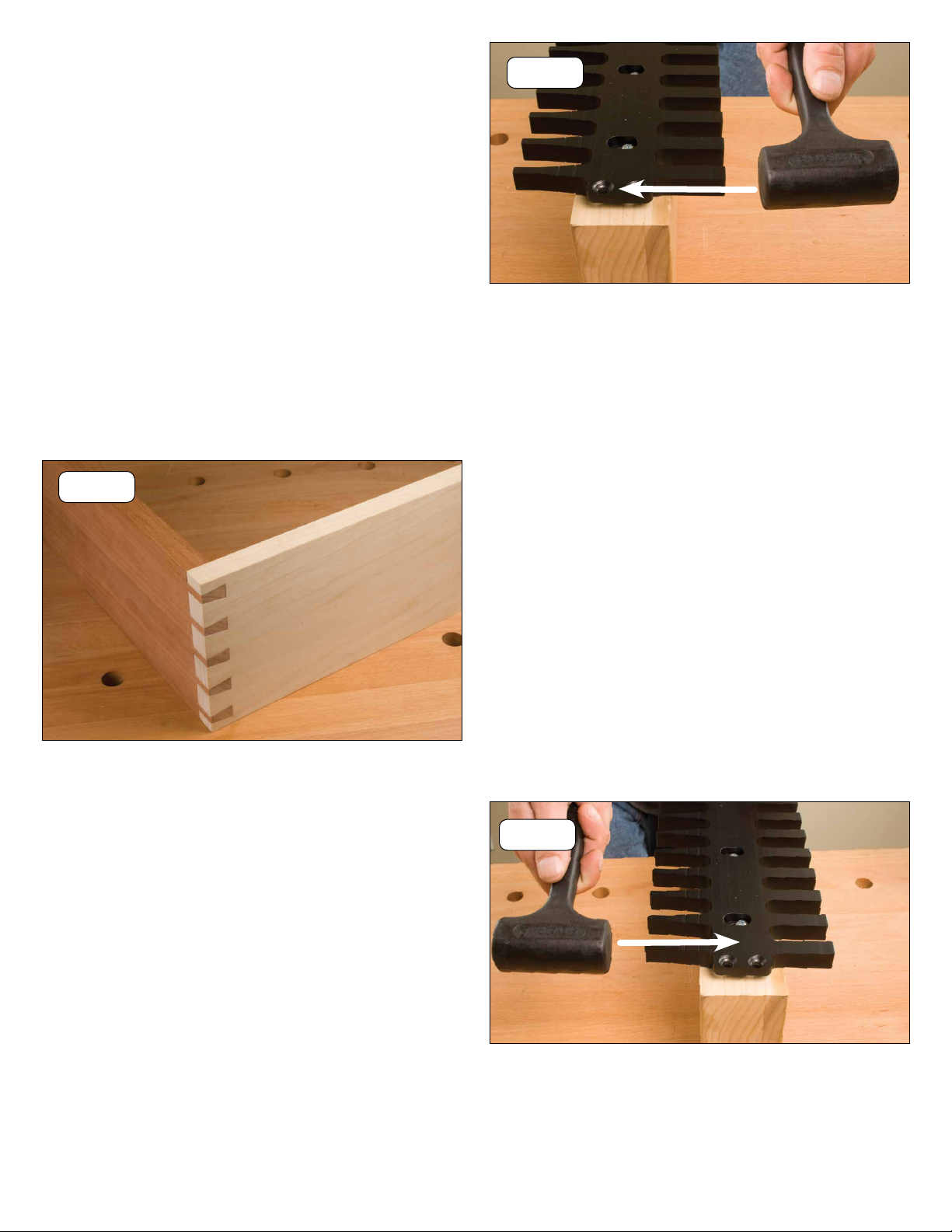

Assemble the Dovetail Joints:

Assemble the pin-board and the tail-board. The Joint

should have a snug - sliding t as shown in Fig. 18.

If you have to force the joint together with a mallet, it

may result in splitting the dovetailed sockets, as well as

forcing the glue out of the joint. To loose of a t, may

produce wobbling and a week dovetail joint. If you

have added the extra 1/32” or more to your joint, it can

now be cleaned up by sanding the joint ush after glu-

ing. If satised with the t of your dovetail joint - glue,

clamp and nish your project. If the dovetails are in

need of adjustment, this is done on the pin side of the

dovetail jig (follow steps below). The tail side or of the

joint remains the same.

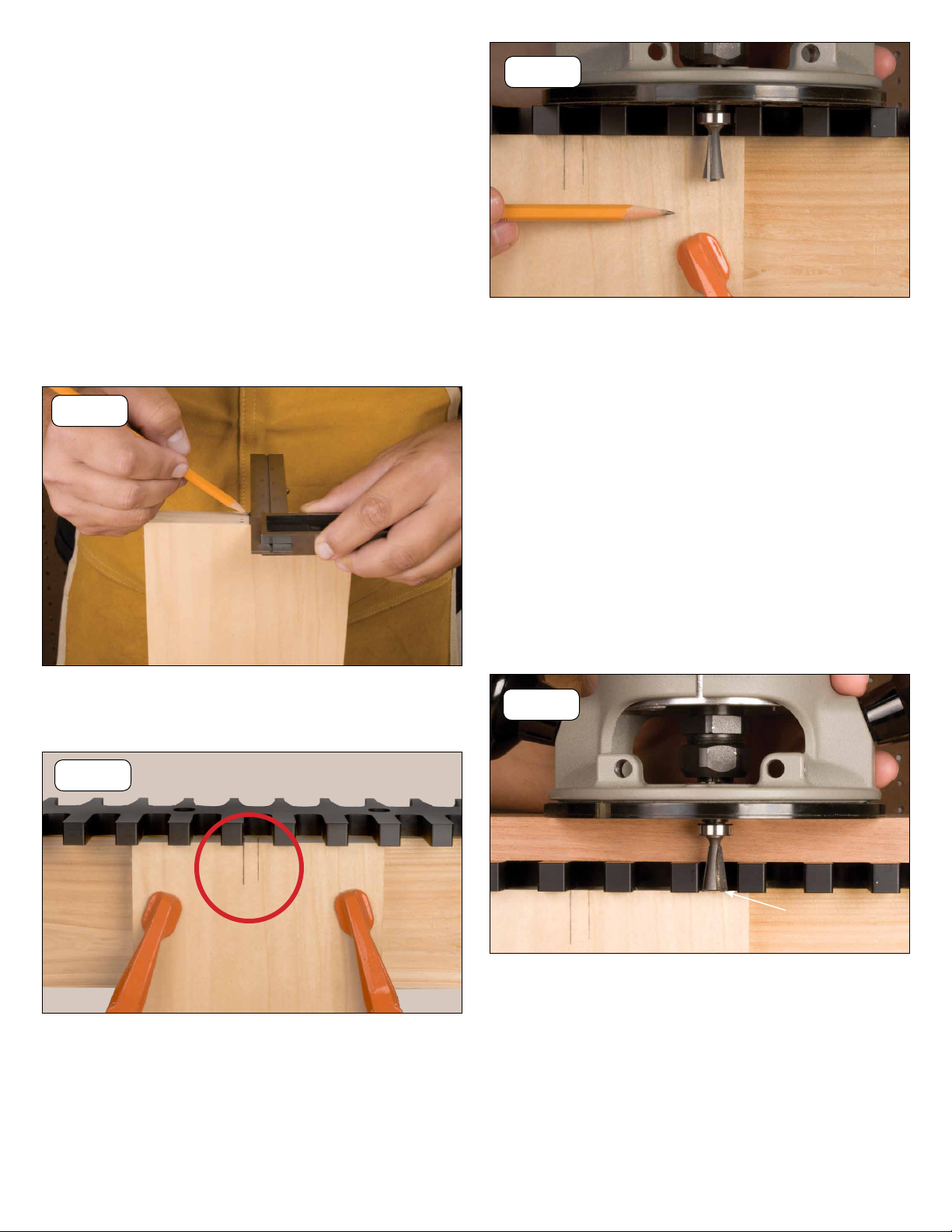

If Joints Are To Loose:

You will need to make the joint tighter, by making

the pins larger, lightly loosen the 4 screws that hold

the dovetail jig to the mounting block, just enough to

be able to tap the jig forward with a wooden mallet

or scrap block of wood (do not use a metal hammer

directly on jig as it may damage the dovetail jig). Tap

the dovetail jig forward on the mounting block. The

distance of this adjustment usually is made in .001”

depending upon how loose the joint is. Start out by

tapping the dovetail jig forward on the block .002” See

Fig. 19. This means that each pin size is increased by

.004” wider (.002” on each side of the pin = .004”).

Make sure your adjustment remains parallel across

the dovetail jig to the mounting block. Once adjusted,

tighten the four screws - repeat cutting process with dif-

ferent piece of stock until you obtain the desired t.

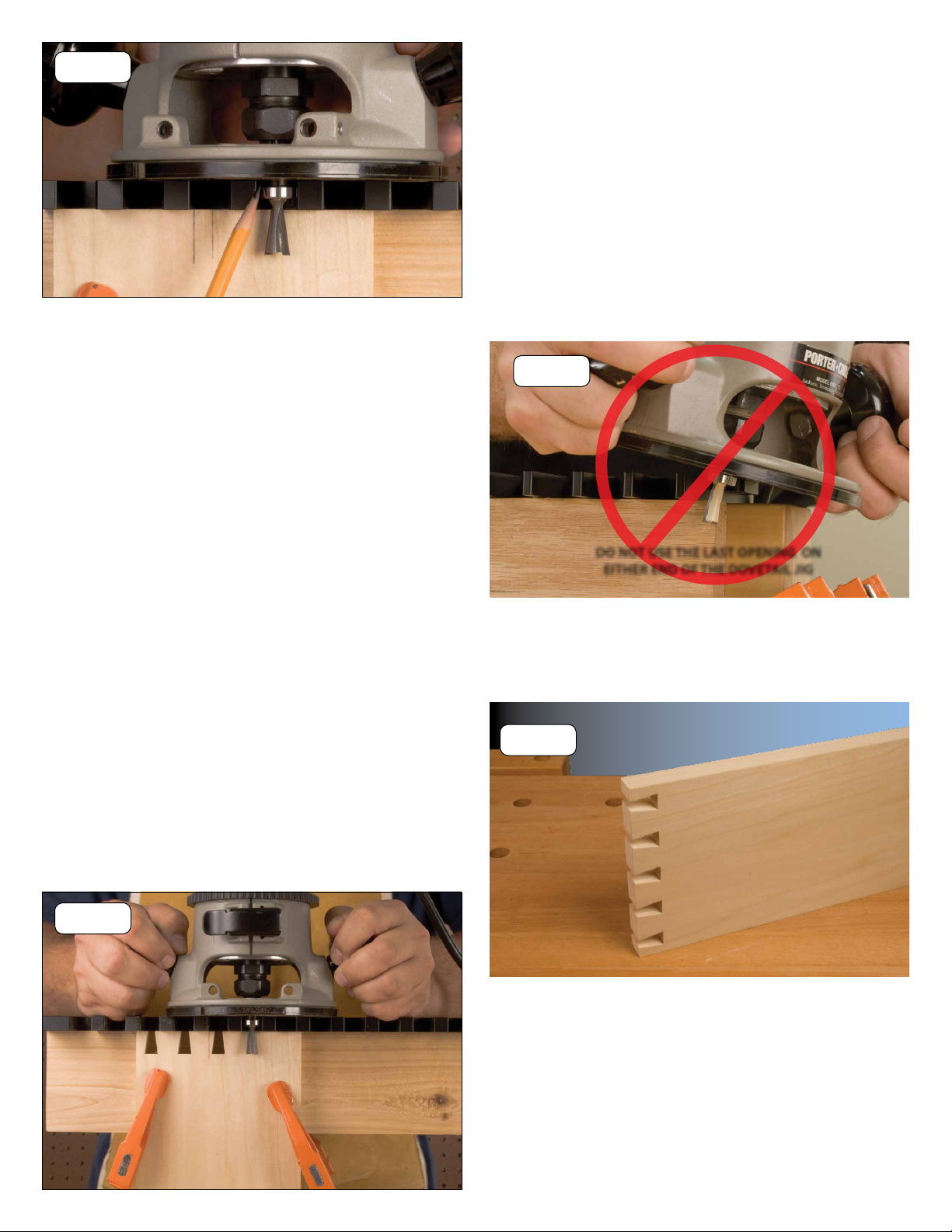

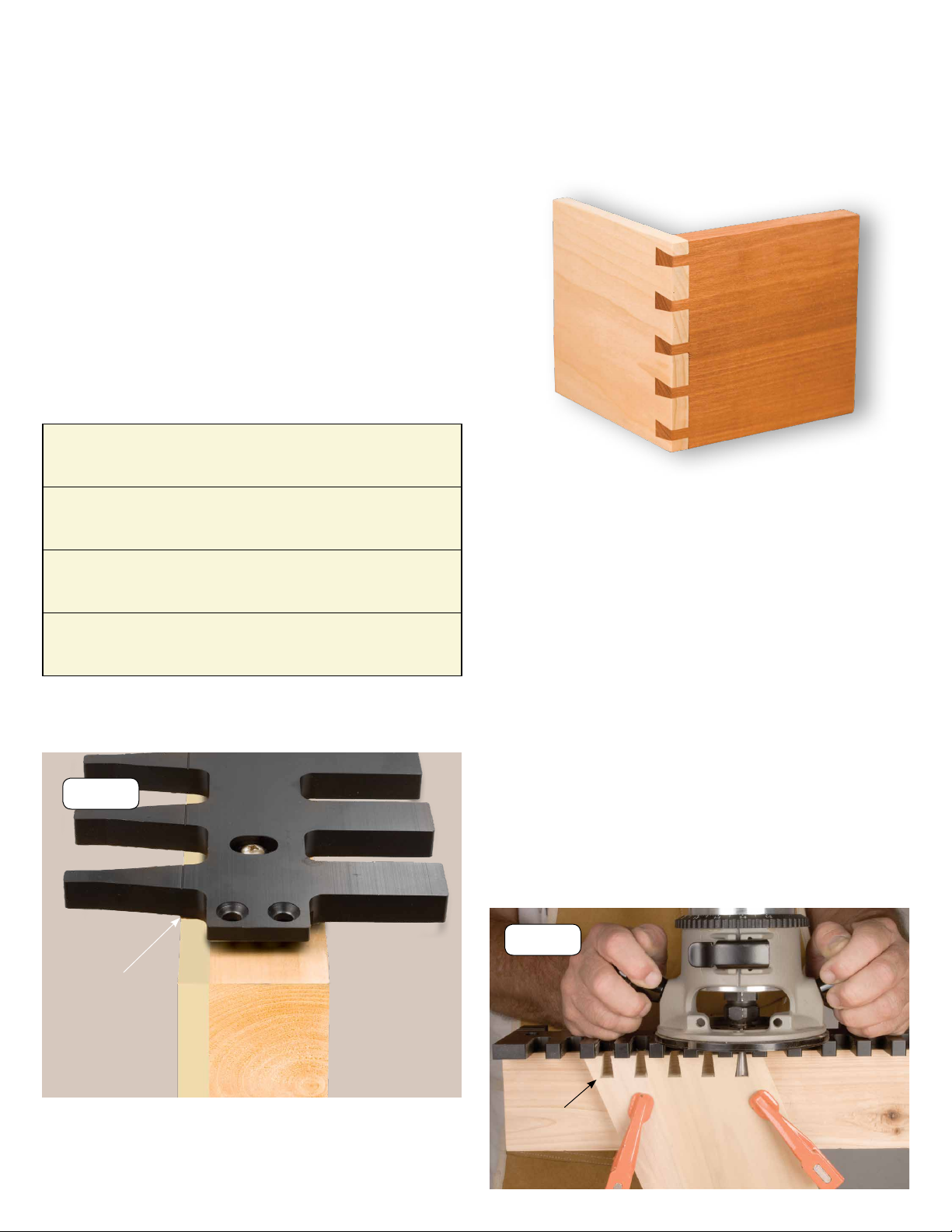

If joints are to tight:

You will need to make the joint looser by making the

pins smaller, slightly loosen the 4 screws that hold

the dovetail jig to the mounting block, just enough to

be able to tap the jig backward with a wooden mallet

or scrap block of wood (do not use a metal hammer

directly on jig as it may damage the dovetail jig). Tap

the dovetail jig backward on the mounting block. The

distance of this adjustment usually is made in .001” de-

pending upon how tight the joint is. Start out by tapping

the dovetail jig backward on the block .002”. See Fig.

20. This means that each pin size is decreased by .004”

smaller (.002” on each side of the pin = .004”). Make

sure your adjustment remains parallel across the dove-

tail jig to the mounting block. Once adjustment is made,

tighten four screws and repeat cutting process with dif-

ferent piece of stock until you obtain desired t.

Fig.20

Fig.19

Fig.18

Tap jig

Tap jig

Shop Notes:

When making test cuts it is important that your test

stock is exactly the same size thickness as your project

stock. Each time you change the thickness of your stock,

you must adjust the dovetail jig accordingly.

Shop Notes:

When making test cuts it is important that your test

stock is exactly the same size thickness as your project

stock. Each time you change the thickness of your stock,

you must adjust the dovetail jig accordingly.