114605-001 - Product Manual - #1557 Infrared Construction Heater - Revision 09 - 11-11-2014 Page 7

2.0 - Introduction & Product Information

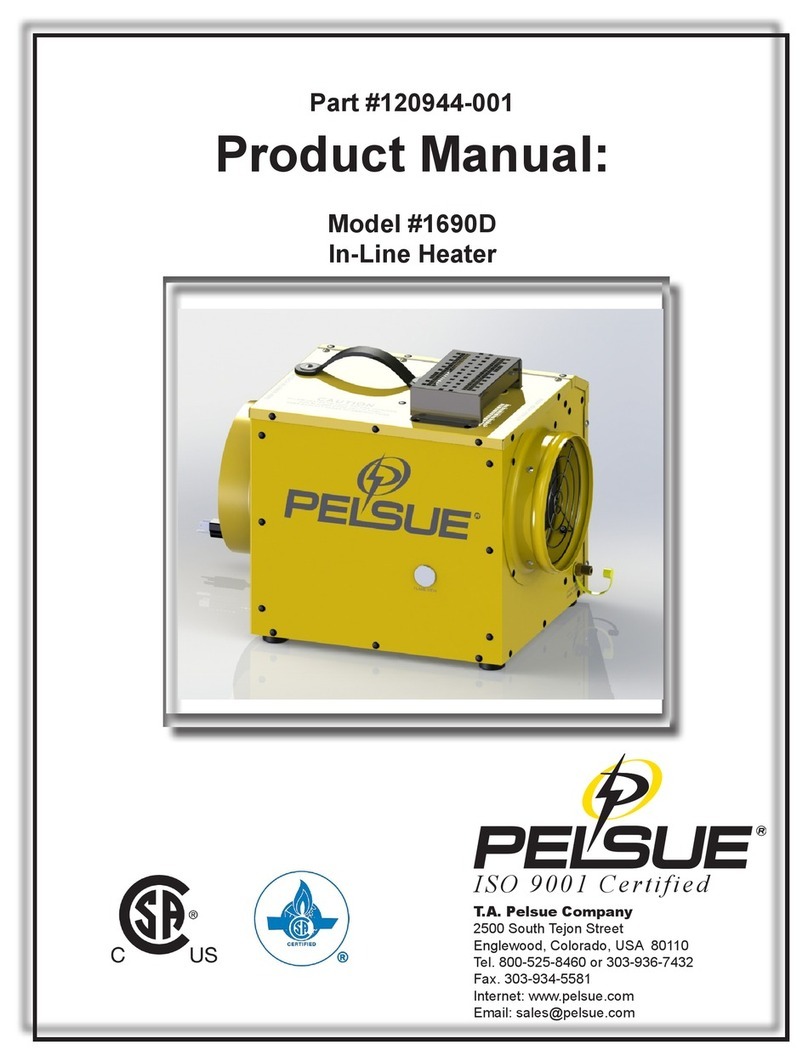

Congratulations on your choice of a Pelsue Model #1557 Infrared Construction Heater. The Pelsue Infrared Heater is

specically designed to provide means of heating ventilated shelters or work areas. Such use includes, but is not limited

to Fire, Police & Hazmat response crews in bio-terror and mass casualty incidents. This equipment has been designed

and manufactured to exceed durability requirements in order to meet the needs of the discriminating operator. Safe,

efcient and trouble-free operation and maintenance of the system requires that anyone who will be operating, main-

taining, or inspecting the equipment, read, understand and follow all the operation, safety, maintenance, and inspection

instructions contained within this manual. This manual covers the Pelsue Model #1557 Infrared Construction Heater.

Use the Table of Contents as a guide to nd specic information.

Keep this manual available for future reference if required, and as a tool in the training of new operators.

This product is part of a system indented for usage

in a climate control scenario. The user must read,

understand and follow the instructions contained in

this manual before using this equipment. Failure to

follow these instructions could result in serious injury

or death.

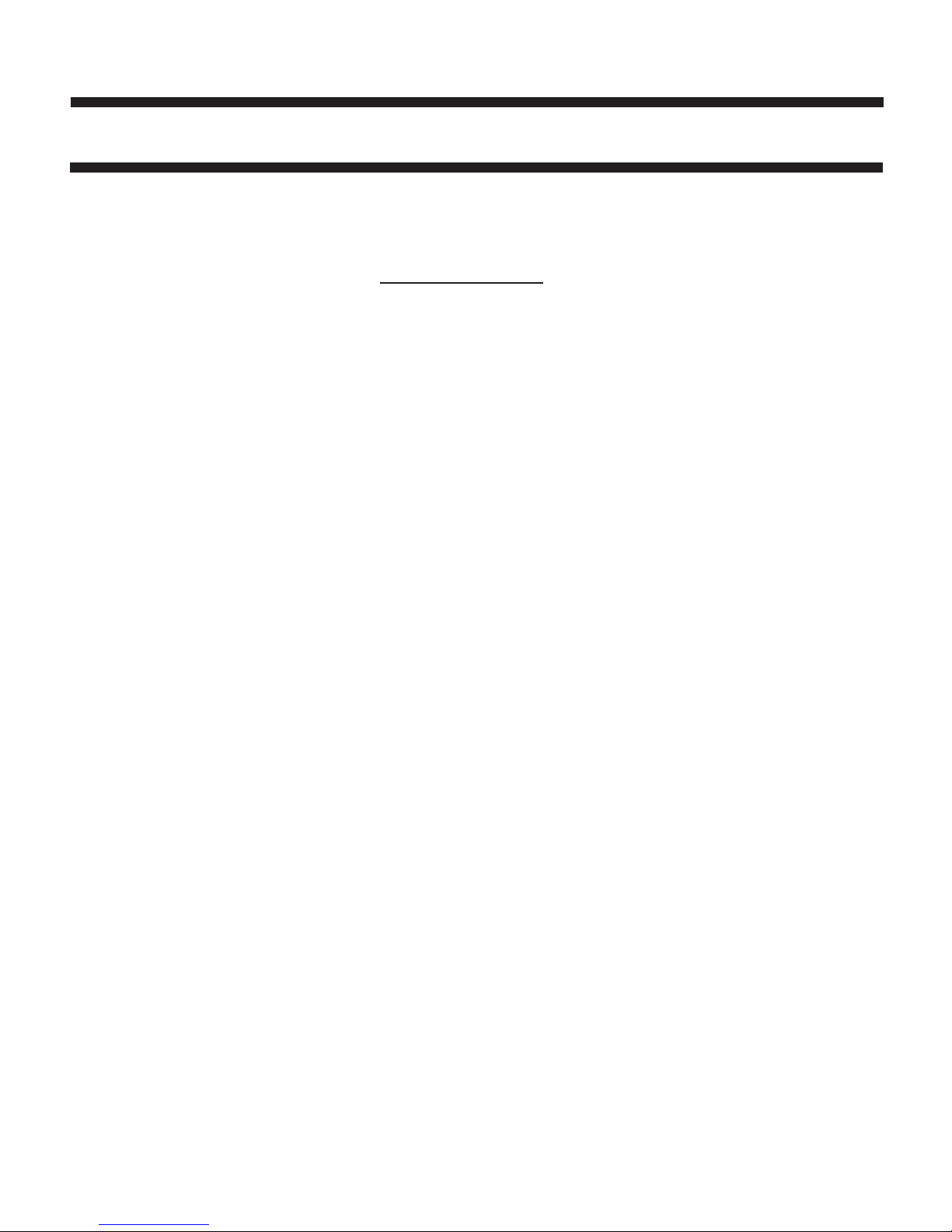

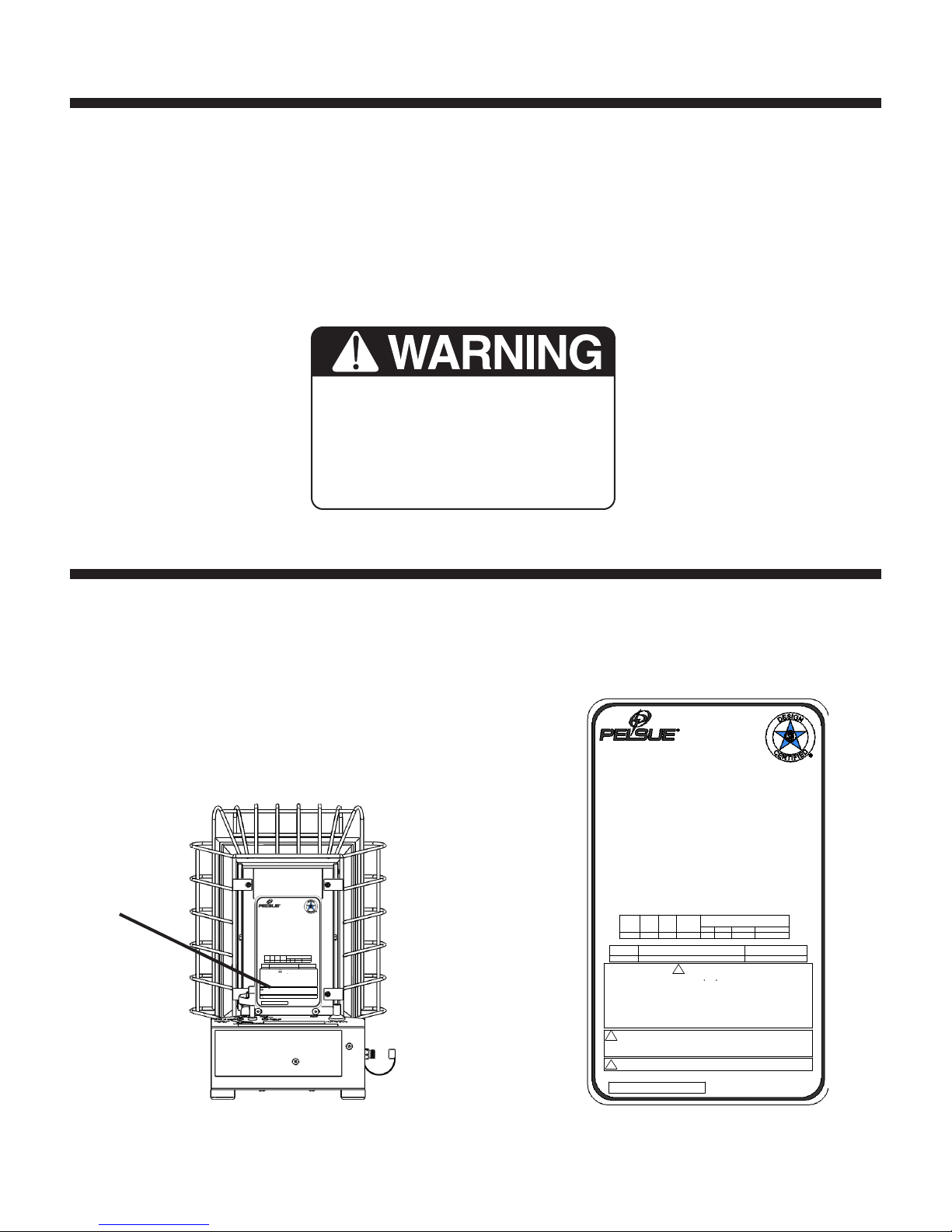

2.1 - Serial Number

Always give your dealer the serial number of your Pelsue portable infrared heater product when ordering parts or request-

ing service or other information.The rating and serial number decal is permanently embossed with a serial number. The

serial number decal is located on the rear heat shield as shown in

Fig. 2a

. The serial number decal will appear as shown

in

Fig. 2b.

A space has been provided below for the recording of the serial number for future reference.

Figure 2b: #1557

Serial Number Decal

MODEL:__________________________________________

Serial Number :_____________________________________

#1557

SERIAL

NUMBER

LOCATION

Figure 2a: Serial Number

Location

NOTES:

MATERIAL: AVERY PX 2071-P/905-MATTE CHROME POLYESTER FILM,

.002 THICK WITH HIGH TACK PERMANENT ACRYLIC ADHESIVE

IAW-UL FILE MH-11912 (N) CAT. PGGU2

**THE TEXT: "1557- " IS TO BE IMMEDIATELY FOLLOWED BY

A SERIAL NUMBER STRING EACH DECAL BEING UNIQUE SERIAL NUMBER

DETAIL: CSA LOGO ARTWORK

SCALE 2 : 1

NOTE:

COLOR BLACK: ROUND BORDERS, STAR BORDER

LETTERING & CSA LOGO

COLOR BLUE: INSIDE OF STAR BORDER

SCALE 2 : 1

DETAIL: PELSUE LOGO ARTWORK

NOTE:

COLOR BLACK: ENTIRE LOGO

BTUH

NO.

1557

MIN.

BTUH

INPUT INPUT

1557-

350 PSI

P/N 114609-001

ENG :\

CHAU 08-2 2-11

DRI V E :

250 0 SOUTH T EJON S TREE T

ONEWITHOUT THE PERMISSIONOF THE T.A.PELSUE COMPANY."

SCALE 1:1

DO NOT SC ALE DRA WING

TRE A T M E N T

UNLE SS OTH ERWI SE SPE CIFIE D

TOLERANCE S ARE:

DIMEN SIONS A RE IN INC HES

FI NI S H

PAR T NU MB E R

DA T E TITLE

APP R O V AL S

CO N T R A C T NO .

DR A W N :

08-25-11DU K E

TO B E REPR ODUC ED, US ED, OR D ISCL OSED I N WHOL E OR IN P ART TO A NY-

ENG LEWO OD, CO LORA DO 8011 0 USA

SHE E T

FS C M NO . DW G . NO . RE V .

114609

114609-00 1

PLA TE DE CAL - I. D. & SE RIAL #

HEA TER O PERA TING I NSTR UCTI ONS

#15 57 CON STRU CTIO N HEAT ER

B

1 0F 1

05

O:\P ortab le\Dr awing s - Porta ble\11 4609. SLDDR W

NO N E

REF ER TO N OTES

06- 09- 95

SI Z E

0.010

PO RT AB LE

"T HIS DO CUME NT AND T HE DAT A DISC LOSE D HERE IN OR HE REW ITH IS N OT

REV IS I O N :

LAT E S T

F. K. H OWEL L

FRACTIONS DECIMALS ANGLES

1/16 X.XX 0.03 2

X.XXX

CHE C K E D &

REL E A S E D :

ZONE REV. DESCRIPTION DATE B Y

00 ISSUED FOR FABRICATION 09-06-95 HOWELL

01 TEXT UPDATED 10-09-95

02 NEW CSA LOGO. WAS B-SIZE DRAWING 07-25-01 D. HAM

03 CHNG. WORD PUSHING WAS ROTATING, CHNG.

WORD BUTTON WAS KNOB. LINE #4 02-04-02 D. HAM

04 CHNG. WORD BRASS WAS RED, LINE 4 & 5 LINE 4

LEFT WAS RIGHT & RIGHT WAS LEFT 12-02-05 D. HAM

ALL 05

DRAWING REVISED, REMOVED REFFERENCE TO

QUICK CONNECT FITTING, REMOVED

REFERENCES TO "BRASS" BUTTON

08-22-11 CHAU

NOTES:

MATERIAL: AVERY PX 2071-P/905-MATTE CHROME POLYESTER FILM,

.002 THICK WITH HIGH TACK PERMANENT ACRYLIC ADHESIVE

IAW-UL FILE MH-11912 (N) CAT. PGGU2

**THE TEXT: "1557- " IS TO BE IMMEDIATELY FOLLOWED BY

A SERIAL NUMBER STRING EACH DECAL BEING UNIQUE SERIAL NUMBER

DETAIL: CSA LOGO ARTWORK

SCALE 2 : 1

NOTE:

COLOR BLACK: ROUND BORDERS, STAR BORDER

LETTERING & CSA LOGO

COLOR BLUE: INSIDE OF STAR BORDER

SCALE 2 : 1

DETAIL: PELSUE LOGO ARTWORK

NOTE:

COLOR BLACK: ENTIRE LOGO

BTUH

NO.

1557

MIN.

BTUH

INPUT INPUT

1557-

350 PSI

P/N 114609-001

ENG:\

CHAU 08-22-11

DRIVE:

2500 SOUTH TEJON STREET

ONE WITHOUT THE PERMISSION OF THE T.A. PELSUE COMPANY."

SCALE 1:1

DO NOT SCALE DRAWING

TREATMENT

UNLESS OTHERWISE SPECIFIED

TOLERANCES ARE:

DIMENSIONS ARE IN INCHES

FINISH

PART NUMBER

DATE TITLE

APPROVALS

CONTRACT NO.

DRAWN:

08-25-11DUKE

TO BE REPRODUCED, USED, OR DISCLOSED IN WHOLE OR IN PART TO ANY-

ENGLEWOOD, COLORADO 80110 USA

SHEET

FSCM NO. DWG. NO. REV.

1146 09

114609-001

PLATE DECAL - I.D. & SERIAL #

HEATER OPERATING INSTRUCTIONS

#1557 CONSTRUCTION HEATER

B

1 0F 1

05

O:\Portable\Drawings - Portable\114609.SLDDRW

NONE

REFER TO NOTES

06-09-95

SIZE

0.010

PORTABLE

"THIS DOCUMENT AND THE DATA DISCLOSED HEREIN OR HEREWITH IS NOT

REVISION:

LATEST

F. K. HOWELL

FRACTIONS DECIMALS ANGLES

1/16 X.XX 0.03 2

X.XXX

CHECKED &

RELEASED:

ZONE REV. DESCRIPTION DATE B Y

00 ISSUED FOR FABRICATION 09-06-95 HOWELL

01 TEXT UPDATED 10-09-95

02 NEW CSA LOGO. WAS B-SIZE DRAWING 07-25-01 D. HAM

03 CHNG. WORD PUSHING WAS ROTATING, CHNG.

WORD BUTTON WAS KNOB. LINE #4 02-04-02 D. HAM

04 CHNG. WORD BRASS WAS RED, LINE 4 & 5 LINE 4

LEFT WAS RIGHT & RIGHT WAS LEFT 12-02-05 D. HAM

ALL 05

DRAWING REVISED, REMOVED REFFERENCE TO

QUICK CONNECT FITTING, REMOVED

REFERENCES TO "BRASS" BUTTON

08-22-11 CHAU