F261 Series Fluid Flow Switches Product Bulletin2

Application

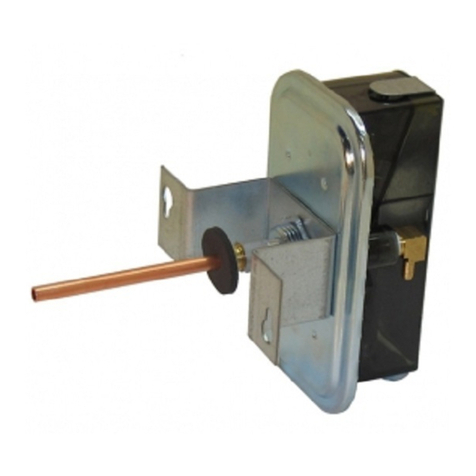

Standard Flow Switches

Use F261 Series Standard Flow Switches in

applications with fluid pressures up to 290 psig

(20 bar). A typical application for a standard F261 flow

switch is to shut down the refrigeration compressor on

a fluid chiller system if flow stops, reducing chances of

chiller freeze-ups.

Type 3R (NEMA) / IP43 Enclosures

Use models with Type 3R (NEMA) / IP43 enclosures

for indoor or outdoor applications where they are

protected from weather and splashing water. Use these

models with pipes carrying fluids at temperatures in the

range of -20°F to 250°F (-29°C to 121°C). A drain hole

allows Type 3R (NEMA) models to be used in

applications where the fluid temperature is below the

ambient dew point temperature. The drain hole

knockout is plugged on IP43 models to prevent the

intrusion of objects 1 mm Ø and greater. Removing the

plug reduces the enclosure rating to IP23, allowing

these models to be used in applications where the fluid

temperature is below the ambient dew point

temperature. Do not use these models in applications

or environments where the temperature may cause the

fluid to freeze.

Type 4 (NEMA) / IP67 Enclosures

Use models with Type 4 (NEMA) enclosures for indoor

or outdoor applications in high humidity environments.

Use these models with pipes carrying fluids at

temperatures in the range of -20°F to 250°F (-29°C to

121°C). A sealing O-ring between the cover and case

allows these models to be used in high-humidity

environments, or applications where the fluid

temperature is below the ambient dew point

temperature. Do not use these models in applications

or environments where the temperature may cause the

fluid to freeze.

Media Compatibility

F261 Series Flow Switches are compatible with several

common media:

• water

• ethylene glycol

•brine

•seawater

• swimming pool water

• lubricating oils

IMPORTANT: All F261 Series Flow Switches are

intended to control equipment under normal

operating conditions. Where failure or malfunction of

an F261 Flow Switch could lead to an abnormal

operating condition that could cause personal injury

or damage to the equipment or other property, other

devices (limit or safety controls) or systems (alarm

or supervisory) intended to warn of, or protect

against, failure or malfunction of the F261 Flow

Switch must be incorporated into and maintained as

part of the control system.

IMPORTANT: Do not install oruse this F261 Series

Flow Switch in or near environments where

corrosive substances or vapors could be present.

Exposure of the F261 Series Flow Switch to

corrosive environments may damage the device’s

internal components and will void the warranty.

IMPORTANT: Do not use F261 Series Flow

Switches where the fluid in the pipes drops below

the fluid’s freezing point, causing an internal

freeze-up.