Operation

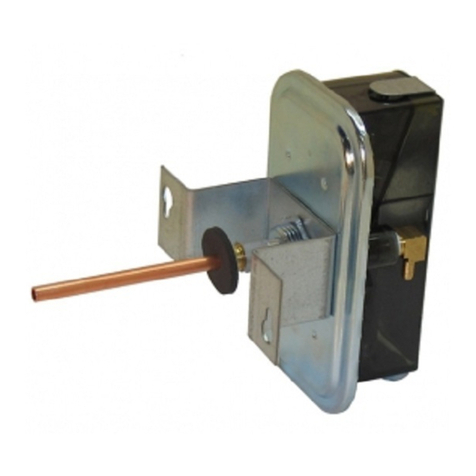

The flow switch responds to pressure that the flowing

fluid exerts on the fluid paddle. A range adjustment screw

adjusts the rate of the flow required to activate the switch.

For flow rates, see Table 7 through Table 9. For pressure

drop against flow rate, see Figure 14.

The red terminal is the Common. Red to yellow closes on

flow increase. Red to blue closes on flow decrease.

Table 10: F261 control switch action

Flow action Switch closure

Increase Red to yellow

Decrease Red to blue

Checkout procedure

Ensure that installation, wiring, and control settings are

according to the application requirements. Refer to the

controlled system’s manufacturer specifications for the

correct settings when adjusting these controls.

Apply power to the control and controlled equipment.

Cycle the controlled system at least three times at normal

operating conditions.

Repair information

Do not make field repairs, except for replacement of the

flow paddle. For a replacement control or paddle kit,

contact the nearest Johnson Controls®/Penn® distributor.

For more information, contact Johnson Controls/Penn

application engineering at 1-800-275-5676.

Troubleshooting

Table 11: Troubleshooting

Symptom Solution

Condensate water

appears within the

enclosure.

If the control has a Type 3R/IP43

enclosure, inspect the grommet

in the field-installed cable gland

or conduit fitting, and replace the

grommet if it is defective.

If the control has a Type 4/

IP67 enclosure, inspect the

case-to-cover O-ring provided

on the flow switch. Ensure

that the O-ring is in place and

undamaged. Ensure that the

control uses a correct cable

gland or conduit fitting for Type

4/IP67 applications.

Fluid from the

tank leaks into the

enclosure due to a

rod seal failure.

Replace the flow switch.

The switch does

not activate due to

debris in the switch

mechanism.

Clear any debris from within

the switch mechanism. Test the

operation of the switch several

times for correct operation.

The control switch

action is reversed.

Ensure that the connections

follow the wiring diagrams.

Table 11: Troubleshooting

Symptom Solution

The control does not

switch.

Check the electrical connections.

The switch fails to

return to the no-flow

position.

The switch may be set lower than

the factory setting. Increase the

setting.

On vertical pipes, ensure that the

direction of flow is up. The arrow

on the switch enclosure must

point in the direction of the flow.

The control does

not switch on flow

increase.

Check for a cracked or broken

paddle. Replace the paddle, if

necessary.

F261 electrical ratings

Table 12: F261xxH Series standard controls electrical

ratings

UL 60730/UL 1059 EN 60730Volts 50/60 Hz

24 120 208 240 24 230

Horsepower – 1 1 1 – –

Full load amperes – 16 10 10 – 8

Locked rotor

amperes

– 96 60 60 – 48

Resistive

amperes

16 16 10 10 16 16

Pilot duty VA 125 720 720 720 77 720

Table 13: F261xxL Series low energy controls electrical

ratings, AC current

UL 60730/UL 1059EN 60730Volts AC,

50/60 Hz 4 VAC 24 VAC 120 VAC

1Resistive

amperes1

10 10 10

2Pilot duty VA212 72 360

1 Maximum dry circuit rating: Resistive only, 400 mW at 28

VAC/VDC. After you use a relay at the general rating level,

the dry circuit rating is no longer valid.

2 Meets UL 100,000 cycle UL endurance test requirement at

switch with Tmin greater than or equal to 32°F (0°C).

Table 14: F261xxL Series low energy controls electrical

ratings, DC current

UL 60730/UL 1059/EN 60730Volts DC

4 VDC 24 VDC 48 VDC

1Resistive

amperes1

111

1 Maximum dry circuit rating: Resistive only, 400 mW at 28

VAC/VDC. After you use a relay at the general rating level,

the dry circuit rating is no longer valid.

F261 Series Flow Switches Installation Guide 9