F261 Series Flow Switches Installation

Guide

Applications

Important:

• Do not install or use this F261 Series Flow Switch in or near environments where corrosive

substances or vapors could be present. Exposure of the F261 Series Flow Switch to corrosive

environments may damage the device’s internal components and will void the warranty.

• Do not use F261 Series Flow Switches where the fluid in the pipes drops below the fluid’s

freezing point, causing an internal freeze-up.

Important: Use this F261 Series Flow Switch only as an operating control. Where failure

or malfunction of the flow switch could lead to personal injury or property damage to the

controlled equipment or other property, additional precautions must be designed into the

control system. Incorporate and maintain other devices, such as supervisory or alarm systems

or safety or limit controls, intended to warn of or protect against failure or malfunction of the

flow switch.

Important: Utiliser ce F261 Series Flow Switch uniquement en tant que dispositif de

régulation. Lorsqu'une défaillance ou un dysfonctionnement du flow switch risque de

provoquer des blessures ou d'endommager l'équipement contrôlé ou un autre équipement, la

conception du système de contrôle doit intégrer des dispositifs de protection supplémentaires.

Veiller dans ce cas à intégrer de façon permanente d'autres dispositifs, tels que des systèmes

de supervision ou d'alarme, ou des dispositifs de sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de défaillance ou de dysfonctionnement du flow

switch.

WARNING

Risk

This product is made of a copper alloy, which contains lead. The product is therefore not to be used on

drinking water.

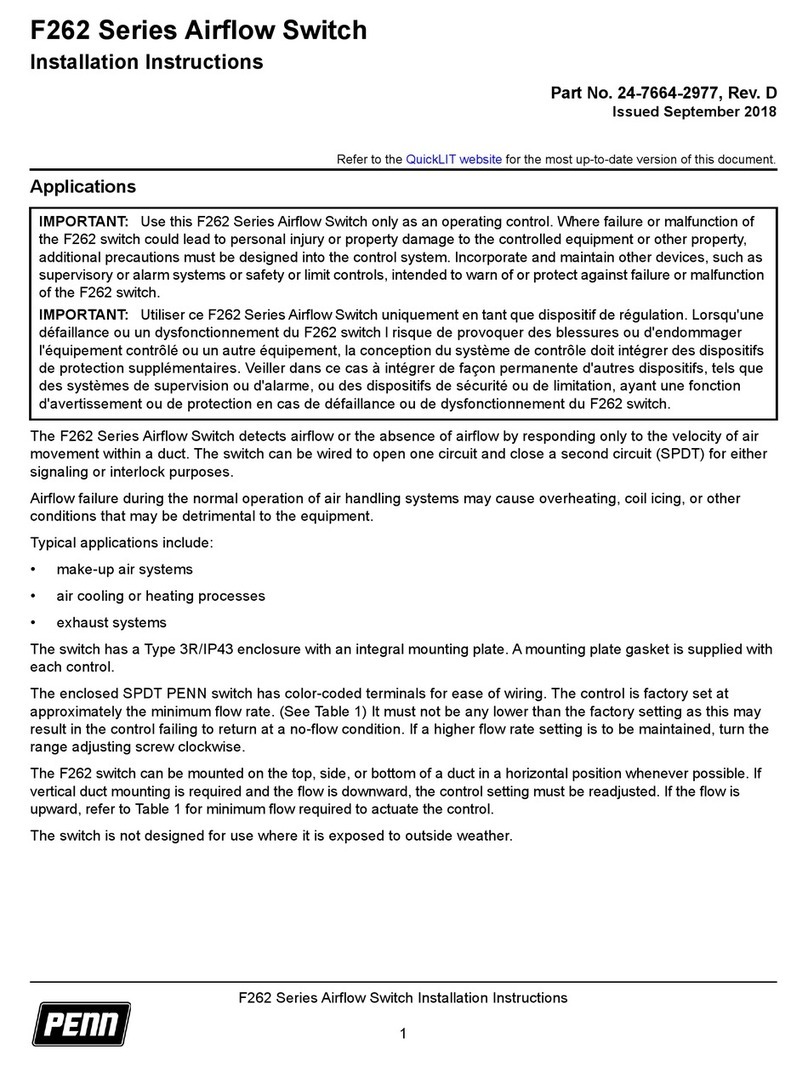

The F261 Series Flow Switches respond to fluid flow in lines carrying water, ethylene glycol, or

other nonhazardous fluids. These models also work in applications with swimming pool water and

lubricating oils.

F261 Series Standard Flow Switches use a variety of paddle sizes to respond to fluid flow rates in

applications with 1 inch trade size (or greater) pipe.

F261 Series Low Flow Switches respond to low fluid flow rates in applications with 1 inch trade size

(or less) pipe.

A low-energy model with gold-plated contacts provides improved electrical performance in low-

voltage, low-current circuits to operate small relays, solenoid valves, and electronic control circuits.

F261KEH, F261MEH, F261KFH, F261MFH

Part No. 24-7664-2969 Rev. E

2019-03-26