F263 Series Liquid Level Switches Installation Instructions

7

Method of Mounting

Control

Mounting to sensed media vessel/orientation

Type 1 or Type 2 Action Type 1.C (Microinterruption)

External Pollution Situation Pollution degree 4

Internal Pollution Situation Pollution degree 2

Rated Impulse Voltage 4,000 VAC

Ball Pressure Temperature Enclosure: 266°F (130°C )

Switch Component: 252°F (122°C)

Control Adjustment

Instruction

-

Field Wiring Rating Wire/Cord Temperature Ratings:

• 140°F (60°C) only permitted when ambient air and media are less than 113°F (45°C)

• 167°F (75°C) only permitted when ambient air and media are less than 140°F (60°C)

• 194°F (90°C) only permitted when ambient air is less than 140°F (60°C) and media is

less than 167°F (75°C)

• 302°F (150°C) permitted when ambient air is less than 140°F (60°C) and media is less

than 249°F (121°C)

Vessel Pressure F263 Liquid Level Float Switch with Copper Float: 100 psi (690 kPa)

F263 Liquid Level Float Switch with Polycarbonate Float: 150 psi (1935 kPa)

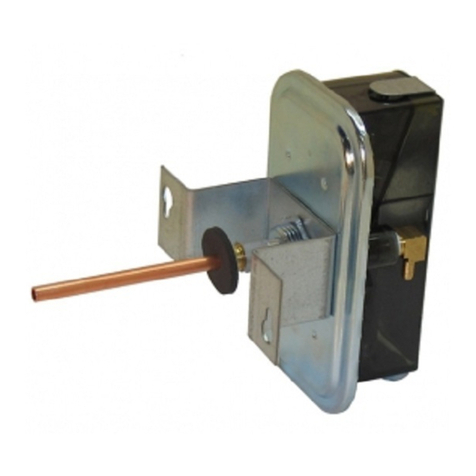

F263 Series Liquid Level Float Switches

Switch SPDT

Enclosure UL: Type 4

CE: IP67

Wiring Connections Three color-coded screw terminals and one ground terminal

Conduit Connection One 7/8 in. (22 mm) hole for 1/2 in. trade size (or PG16) conduit

Pipe Connector 1 in. 11-1/2 NPT threads

Minimum Tank Diameter 9 in. (229 mm)

Maximum Liquid Pressure 100 psig (690 kPa) for copper float

150 psig (1,035 kPa) for polycarbonate float

Liquid Temperature Range Minimum: -40°F (-40°C) or liquid freezing point1

Maximum: 212°F (100°C) polycarbonate, 250°F (121°C) copper2

Ambient Conditions Minimum: -40°F (-40°C)1

Maximum: 140°F (60°C)2

Compliance North America: cULus Listed; UL 60730, File E6688;

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive and the Low

Voltage Directive.

Australia/New Zealand Mark: RCM Compliant

1. Ensure that the low liquid temperature combined with the low ambient temperature does not lead to the freezing the liquid

inside the body (or bellows, where appropriate). Please observe the liquid freezing point.

2. At higher temperatures, the maximum allowed liquid temperature becomes lower. The temperature inside of the electrical

switch should not exceed 158°F (70°C).

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult Johnson Controls/PENN Refrigeration Application Engineering at 1-800-275-5676. Johnson Controls shall not be liable

for damages resulting from misapplication or misuse of its products.

Table 3: UL Conformity Declaration Information (Part 2 of 2)