1

Refer to the QuickLIT website for the most up-to-date version of this document.

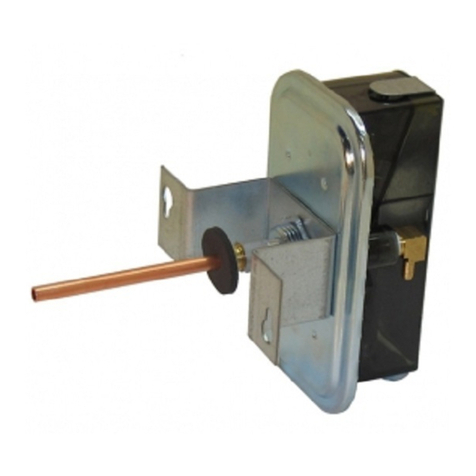

F262 Series Airflow Switch Installation Instructions

Applications

The F262 Series Airflow Switch detects airflow or the absence of airflow by responding only to the velocity of air

movement within a duct. The switch can be wired to open one circuit and close a second circuit (SPDT) for either

signaling or interlock purposes.

Airflow failure during the normal operation of air handling systems may cause overheating, coil icing, or other

conditions that may be detrimental to the equipment.

Typical applications include:

• make-up air systems

• air cooling or heating processes

• exhaust systems

The switch has a Type 3R/IP43 enclosure with an integral mounting plate. A mounting plate gasket is supplied with

each control.

The enclosed SPDT PENN switch has color-coded terminals for ease of wiring. The control is factory set at

approximately the minimum flow rate. (See Table 1) It must not be any lower than the factory setting as this may

result in the control failing to return at a no-flow condition. If a higher flow rate setting is to be maintained, turn the

range adjusting screw clockwise.

The F262 switch can be mounted on the top, side, or bottom of a duct in a horizontal position whenever possible. If

vertical duct mounting is required and the flow is downward, the control setting must be readjusted. If the flow is

upward, refer to Table 1 for minimum flow required to actuate the control.

The switch is not designed for use where it is exposed to outside weather.

IMPORTANT: Use this F262 Series Airflow Switch only as an operating control. Where failure or malfunction of

the F262 switch could lead to personal injury or property damage to the controlled equipment or other property,

additional precautions must be designed into the control system. Incorporate and maintain other devices, such as

supervisory or alarm systems or safety or limit controls, intended to warn of or protect against failure or malfunction

of the F262 switch.

IMPORTANT: Utiliser ce F262 Series Airflow Switch uniquement en tant que dispositif de régulation. Lorsqu'une

défaillance ou un dysfonctionnement du F262 switch l risque de provoquer des blessures ou d'endommager

l'équipement contrôlé ou un autre équipement, la conception du système de contrôle doit intégrer des dispositifs

de protection supplémentaires. Veiller dans ce cas à intégrer de façon permanente d'autres dispositifs, tels que

des systèmes de supervision ou d'alarme, ou des dispositifs de sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de défaillance ou de dysfonctionnement du F262 switch.

F262 Series Airflow Switch

Installation Instructions

Part No. 24-7664-2977, Rev. D

Issued September 2018