FBM(X)20 Basin Mixer Control Panel

Instruction and Service Manual

2

INTRODUCTION:

GENERAL:

Thank you for purchasing your Fairbanks Nijhuis®Basin Mixer Control Panel. To help ensure years of trouble-free operation,

please read the following manual carefully.

BEFORE OPERATION. Read the following instructions carefully. Reasonable care and safe methods should be practiced. Check

local codes and requirements before installation.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related accessories contain chemicals known to the State of California to cause cancer, birth defects or

other reproductive harm.

ATTENTION: This manual contains important information for the safe use of this product. Read this manual completely

before using this product and refer to it often for continued safe product use. DO NOT THROW AWAY OR LOSE THIS

MANUAL. Keep it in a safe place so that you may refer to it often.

UNPACKING PANEL. Remove panel from carton. When unpacking unit, check for concealed damage. Claims for damage must be

made at the receiving end through the delivery carrier. Damage cannot be processed from the factory.

POWER SUPPLY:

WARNING:

Do not attempt to wire this control box unless you have a good working knowledge of electricity and are familiar with the

state and local codes. If you are in doubt about anything, contact a qualified electrician.

Do not attempt to operate this unit on any other voltage or power distribution other than for which it was originally

designed (check nameplate). Failure to comply with this will result in the immediate cancellation of all warranties

and claims.

It is advisable to put the panel on its own circuit using a circuit breaker adequately sized to protect the mixer. Check state and local

codes for the correct wire size and circuit protection to use. The wire should be sized large enough to handle the full load current of

the mixer you are operating and any voltage drop that might occur due to long service runs.

Run power supply lines to the control box and secure (knockouts are not supplied in this box). Select a convenient location on the

bottom to enter the box with the power supply. Cut a hole with a chassis punch. Caution should be taken not to get metal chips in

the components while cutting hole. After the hole is cut, any metal particles must be removed from the box. Failure to do so may

result in premature component failure.

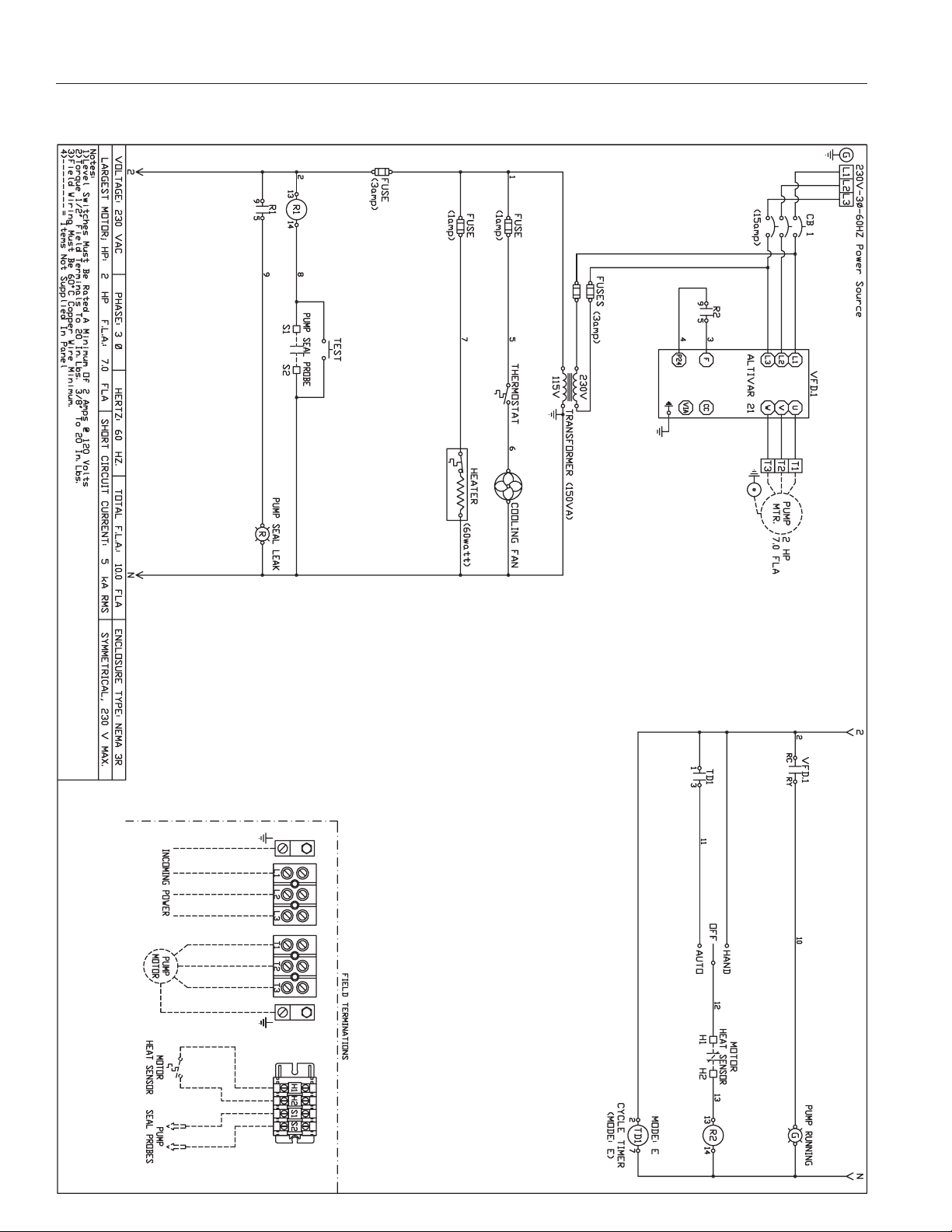

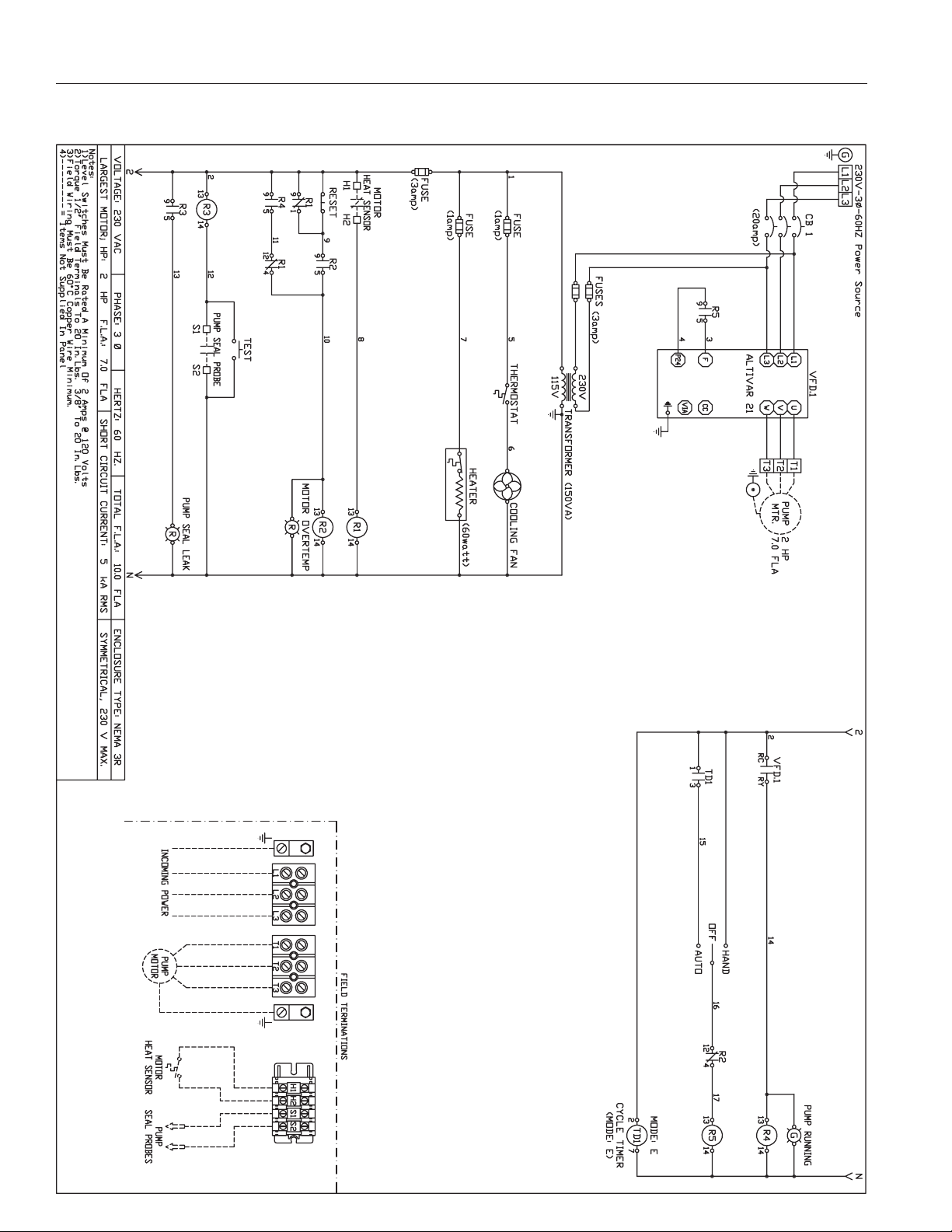

Connect incoming power to the terminal blocks per the included schematic and all necessary ground wires to the ground lug at the

bottom right of the box. The ground lug should be fastened to a good driven earth ground by one of the methods described in the

National Electric Code. NEC does not permit using ground as a current-carrying conductor, therefore a neutral must be provided for

115 volt 1 phase, 208 volt 1 phase, 230 volt 1 phase, or 208 volt 3 phase systems.

WARNING:

Before handling these mixers and controls, always disconnect the power first. Do not smoke or use sparkable electrical

devices or flames in a septic (gaseous) or possible septic sump.

ELECTRICAL CONNECTIONS: The contractor must conform to the latest requirements of the National Electrical Code. All conduit

and cables shall be in accordance with NEC Code NFPA #70. To maintain UL and CSA ENCL rating, use the same type UL and

CSA weatherproof conduit hubs when connecting to this enclosure. Prior to conducting any installation, repair or service with

regard to the control panel, refer to the schematic appropriate for that panel. The schematic will provide guidance with regard to the

terminal block connections.

CAUTION:

A nonmetallic enclosure does not provide grounding conduit connections. Use grounding bushing and jumper wires.

MAKE THE FOLLOWING ELECTRICAL CONNECTIONS:

a. Connect the mixer leads to the control panel.

b. Connect the mixer heat sensor and seal failure leads (if available on the mixer) to the appropriate terminal blocks in the

control panel.

c. Before connecting power to the control panel, make sure all control switches (e.g. H-O-A switch) and protective devices (e.g.

breakers) are in the Off position. Now connect power to the terminal block or the circuit breaker as directed by the schematic.

d. Control panel must be grounded properly per NEC and/or local codes. To facilitate this, a ground lug is provided on the

control panel.