NOTE

Always remove and install element

in

the direction of feed flow. The

feed

end (upstream end)

is

the end plumbed

most directly

to

the p

ump.

When lubricating the vessel

chamfer

,

wear protective gloves or finger cots

t

o

prevent cuts or penetration

of

fiberglass.

Replacing

Element

s

The following procedures are provided for

inform-

ation only. Elements should

be

installed

in accord-

ance with the element manufacturer’s

recommend-

ations. Where conflicts exist, contact the element

manufacturer

or Pentair Water for clarification.

To

replace elements, proceed

as follows.

Removing

El

ements

4. Install adapter if required into one end plug.

At

downstream end of vessel, orient end

plug

ports into desired position and push plug

fully

into vessel. A sharp, forceful thrust may

be

needed to enter plug seal into the vessel

bore.

1.

Remove heads from both ends

of

vessels

as

described

in

Opening the

V

e

ss

e

l

.

2.

Push element out

of

vessel from the

upstream

end.

3.

For multi-element vessels, remove the

inter-

connectors and retain for

reinstallation.

Inserting E

lements

Installation of the End Plug Assembly

into the

vessel

5. Carefully insert retaining ring into its

groove.

This is done by inserting the lead end of

the

spiral retaining ring (end without bent tab)

into

the stainless steel retaining ring groove

located

in the shell, and slowly pushing the

remaining

turns into the

shell.

1. Ensure that heads are available in clean,

as-new

condition before proceeding. (If in doubt as

to

head condition see section on inspecting

parts,

page

9).

2. Check that all required elements are ready for assem-

bly, with no dings or other damage which could

scratch the inside of the vessel.

3. Check that the interior of the vessel is clean and free

o f b u r r s , s h a r p e d g e s o r o t h e r d a m a g e .

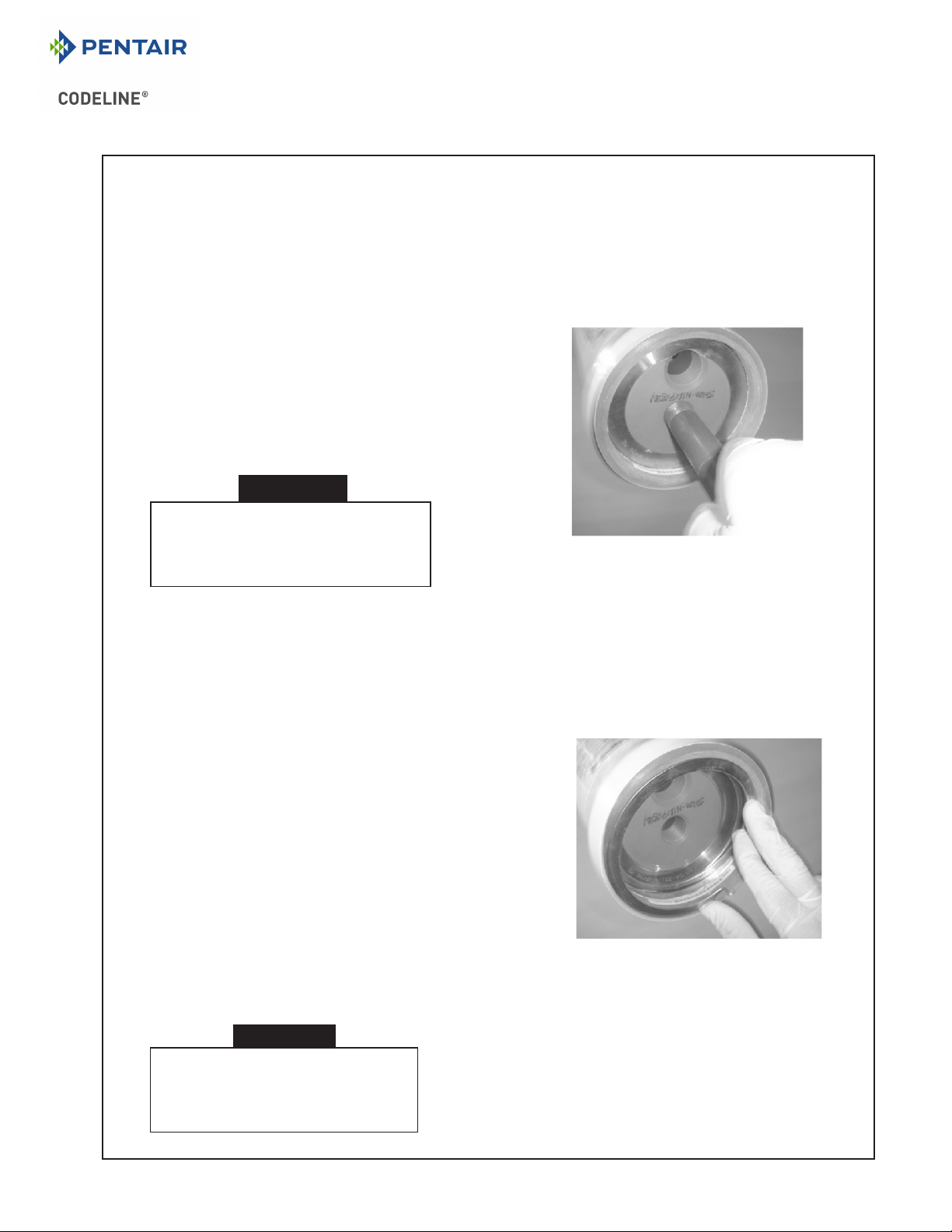

Remove any residual lubricant from the vessel bore

and work a fresh, thin film of Parker-Super O-Lube

TM

silicon lubricant into the lead-in chamfer and an area

approximately ½ inch in from the chamfer

Inserting Retaining Ring into the gr

oove

6. Check that the spiral retaining ring is fully seated

in the groove. If it is not, remove and check for

foreign material that is causing the spiral ring not

to sit into the groove.

Distributed by Applied Membranes, Inc. | www.appliedmembranes.com | (760) 727-3711 | USA