8

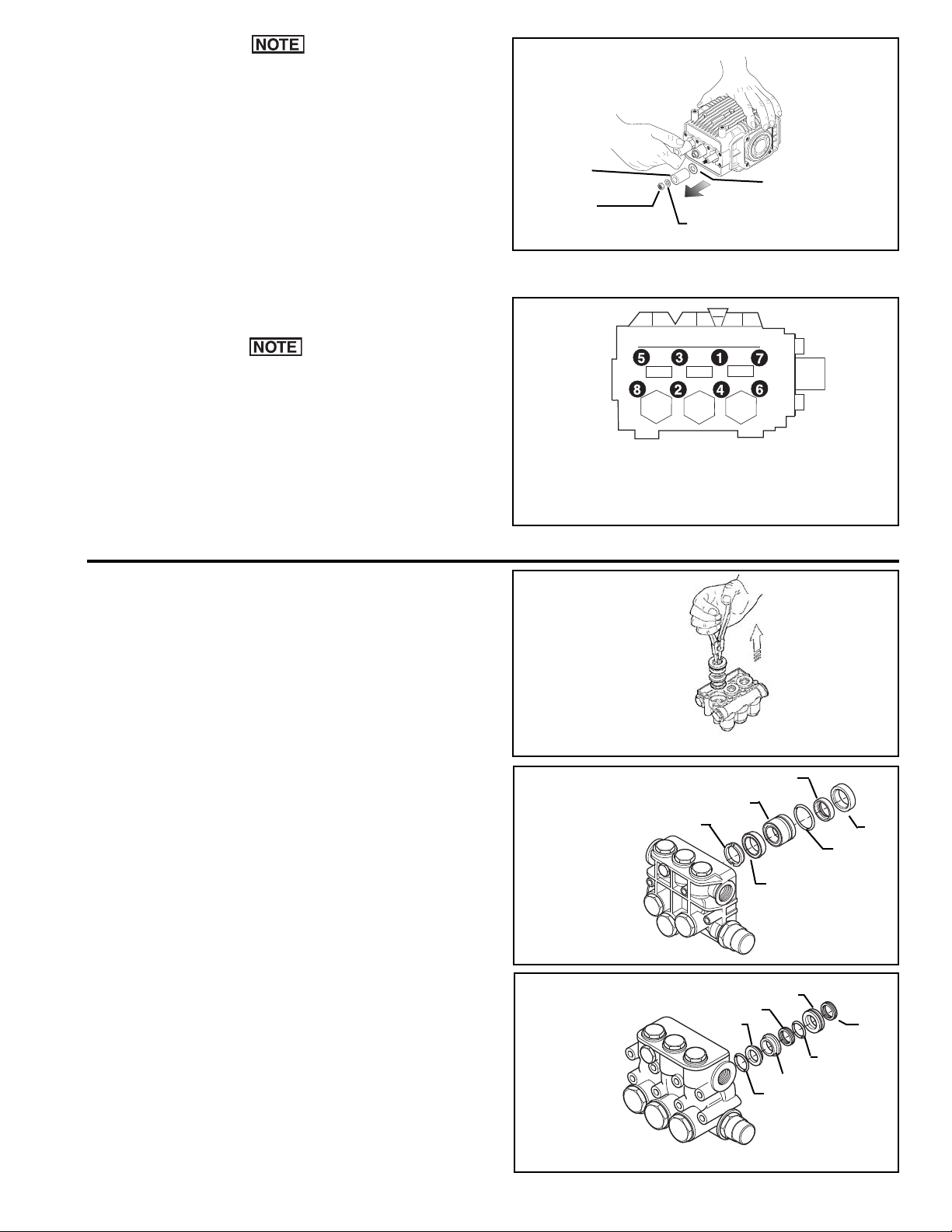

6. nstall new type seal with seal lip facing the large end of the

shaft. Slide the seal over the threaded end of the shaft and

gently push onto the raised area of the shaft. Align the seal lip

to enter the center diameter of the seal spacer and push until

seal body touches seal spacer.

Note: f the seal lip is longer than the seal spacer’s width, please

stop the assembly and review parts being used.

7. Apply a small bead of sealant on outside of the

seal body as shown (Permatex® Form-A-Gasket® No. 2

or Permatex® Gasket Sealant & Dressing No. 09974).

8. dentify new type front spacer provided in kit used only on

old type motors. Discard old front spacer from the

disassembly. (New type front spacer looks like a thick washer

with a counter bore on one side, approx .164 inch thick).

9. nstall new type front spacer by locating the counter

bore side. Face this counter bore towards the seal, and slide

spacer onto small end of shaft until the counter bore fits

onto the seal body.

10. Finished shaft sub-assembly should look like this:

11. Do not press, but place the shaft sub-assembly into the motor

body with threaded end of shaft up, taking care not to dislodge

the front spacer out of its assembled place.

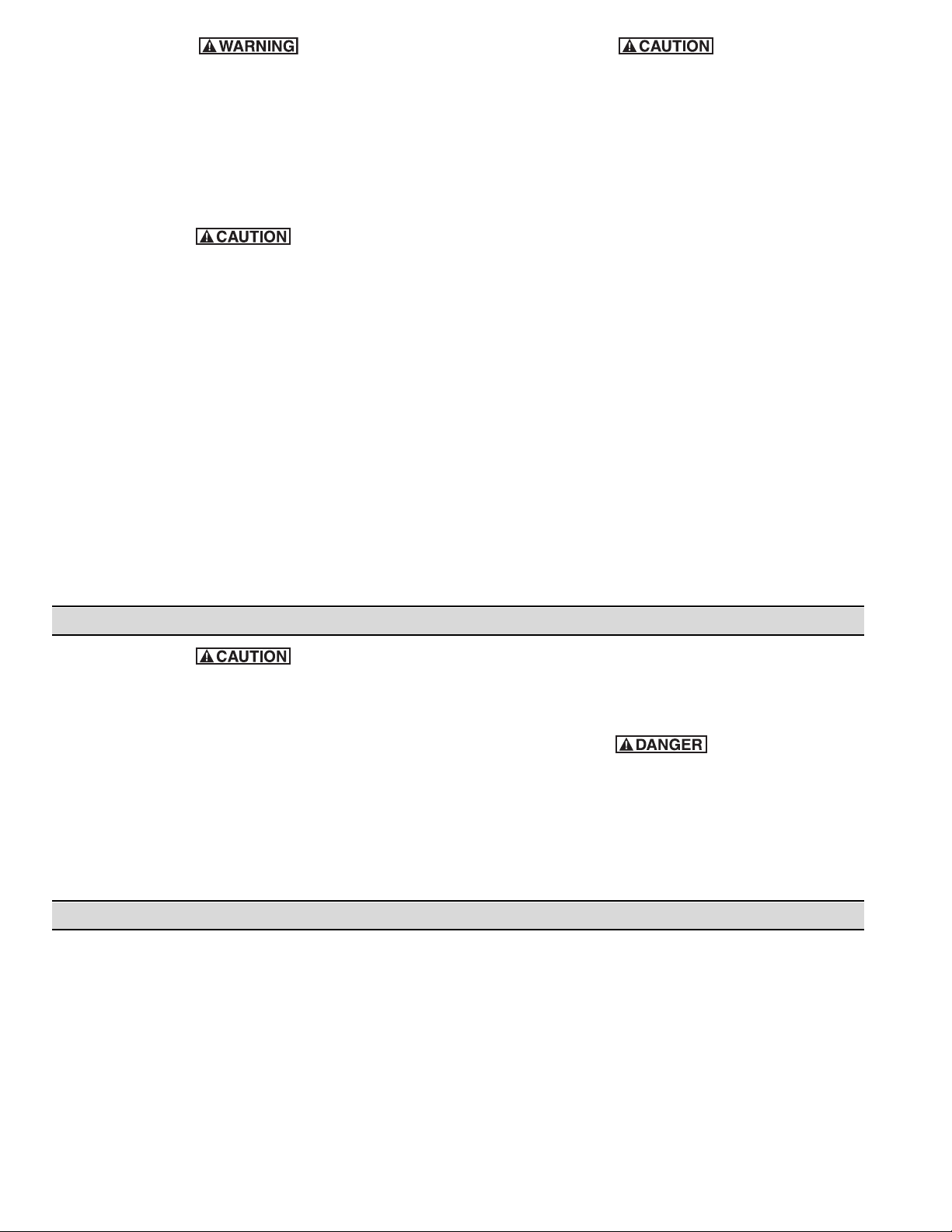

Assembly Instruction for Old Seal-Type Motors

Old Seal Type

Weep hole is present only on motors manufactured with “old” type

hydraulic seal.

1. nstall the large retaining ring onto large diameter end of shaft.

2. From the small threaded end of the shaft, install the following

parts in this order: thrust bearing race, thrust bearing,

2nd thrust bearing race.

Note: The thrust bearing and races should not be reused if they are

showing any signs of wear.

3. nstall new type seal spacer provided in kit. Discard old

spacer from the disassembly. (New type seal spacer

looks like a thick washer, approx .130 inch thick).

4. Before installing the new seal, its lip must be expanded to fit on the

shaft. With the seal lip facing out, slide the seal over the threaded end

of the shaft and gently push the seal onto the raised area of the shaft.

Do not push the seal past the large retaining ring groove on the shaft.

5. Once the seal has been expanded, remove the seal from the shaft.

Weep hole

Reassembly of Remaining ydraulic Motor Parts

1. Place Motor Body in a vise with large end of shaft facing

up.

2. nstall the o-ring in the body.

3. nstall the Roll Pin on the shaft. Place the nner Gear of

the Gerotor onto the shaft making sure Gerotor slot

lines up with the key in the shaft.

The Roll Pin can slide up behind the inner gear of the

gerotor when the gear is installed. Make sure the key is

visible in the slot after the gear is in place.

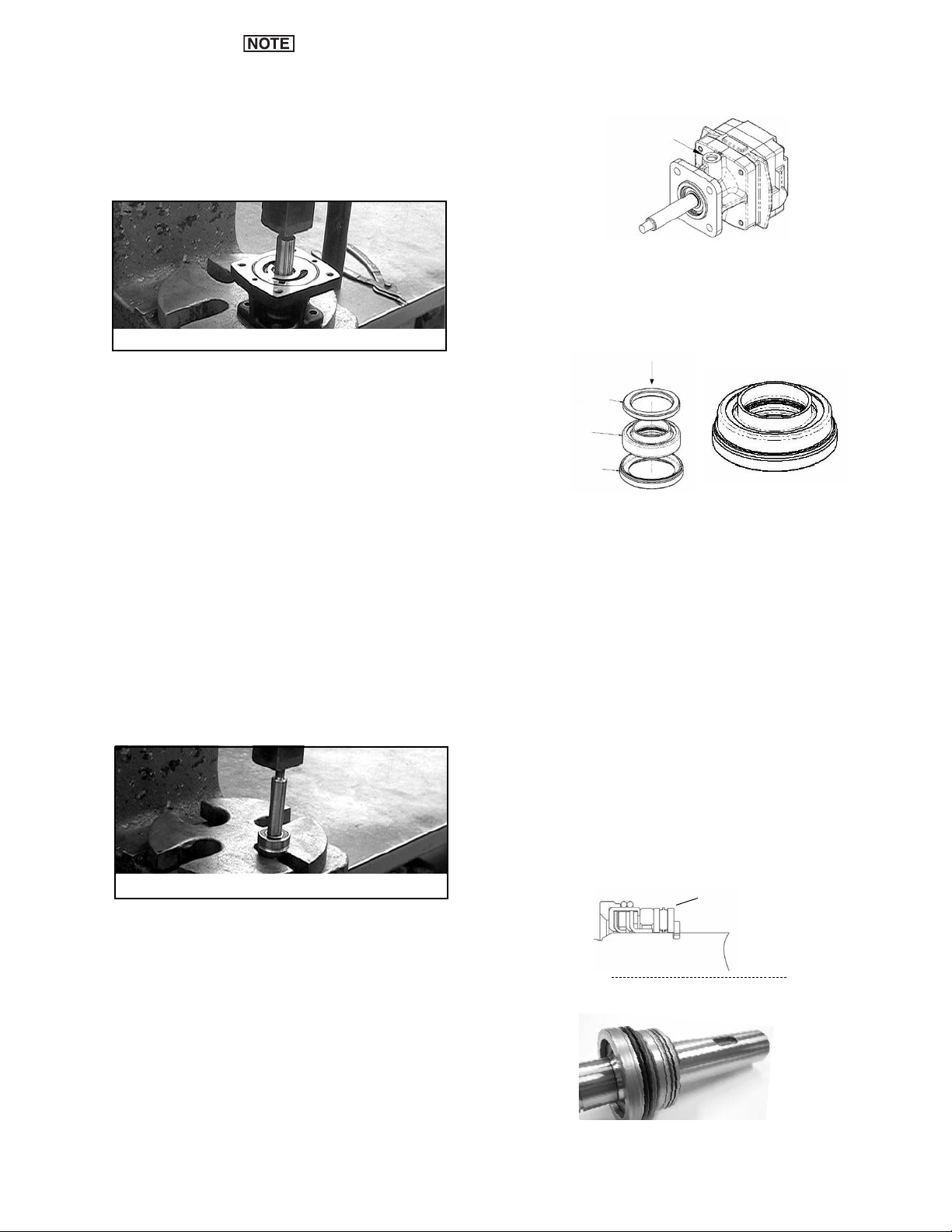

2. nstall the new ball bearing onto the small diameter

end of the shaft. Press down using the 1” x 4” pipe

until the retaining ring can be installed in its groove in

the bearing core of the motor body. nstall the retaining

ring.

3. Turn the motor body assembly over (threaded shaft

end down) on the arbor press. Press the shaft down

into its “final position” until the small retaining ring can

be installed in the shaft next to the ball bearing.

4. nstall small retaining ring on shaft.

5. Check shaft rotation at this point. t should rotate

smoothly with only slight resistance from the seal lip

pressure on the shaft. f you feel any gritty or sticking

movement, return assembly to the arbor press and

lightly press on the threaded end of the shaft to relieve

press fit compression on the thrust bearing. Note:

Don’t over do this press. The objective is to move the

small outer retaining ring installed in the

previous step back to ” touching only” the ball bearing

inner race.

Important: f gritty or sticky movement persists, it’s likely

due to re-used parts or the body needle bearing is in

need of replacement.

Figure 15

Install Shaft Sub-Assembly Into Motor Body

Important: Make sure the surface edge of the arbor press

fixture is smooth and clean. An unthreaded piece of

pipe (1” x 4” high) is needed to support the outer race

of the seal cartridge sub-assembly and outer race of

the ball bearing during assembly. Place this pipe over

the shaft threaded end for assembly of the following

steps.

1. Place the body on a support fixture in the arbor press.

Using an unthreaded piece of pipe (1” dia. x 4” high),

press the shaft subassembly down into the body until

it bottoms out. This is a light press fit and should be

done slow and easy.